Coffee treatment | Coffee treatment that you know or don't know?

Wow! This is what kind of beans, how the flavor is so unique, there is wine, there is fermented flavor, the taste is still so strong, I drink coffee bar! Why doesn't it feel like drinking coffee? let's talk about the treatment of coffee. You know, in addition to brewing and roasting coffee, the treatment of raw beans also has a great impact on the flavor of coffee. What are the coffee treatments you know or don't know about today?

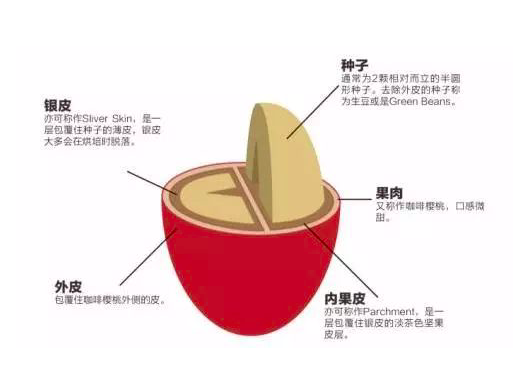

Let's take a look at how the coffee beans come from, let's take a look at the pictures.

From the outside to the inside, it can be roughly divided into pericarp, pulp, pectin layer, hard shell (or sheep's skin), silver skin, and the innermost coffee bean seed. after that, the outer skin and pulp pectin are removed by various treatment methods, and finally sent to people's hands is the innermost coffee bean seed, and finally baked. After extraction with utensils, it becomes the coffee we usually drink ~ do you suddenly have a feeling of knowing in seconds ~ hee hee ~

All right, let's get back to the point. let's first take a look at the treatment of raw coffee beans.

| | Solar treatment |

Sun treatment, one of the most primitive and oldest treatment, the cost of sun treatment is lower, but also a relatively simple treatment, sun treatment is only through a large number of drying to reduce the water content of coffee.

First of all, after screening the coffee fruit, spread the whole coffee fruit with meat belt directly on the cement floor or on the sun bed and dry it naturally to about 12% of the water content, which takes about two to four weeks, depending on the climate of the place of origin. After the coffee fruit is dried, the hard peel, pulp and sheep skin are removed by a shelling machine, and finally it becomes a raw bean. Of course, this method also has its advantages and disadvantages.

Advantages:

Under the premise of proper treatment, alcohol has better thickness and sweetness, which increases the flavor of fruit. for example, beans that we often drink in the sun often have aromas of ripe strawberries, blueberries and berries, or aromas of ripe fruits and fermented wine.

Disadvantages:

However, if it is not handled properly, it is easy to destroy the quality of the coffee and is prone to bad taste, such as soil, fermented taste, wild taste and so on. Because the coffee is basked on the ground and completely opened in the surrounding environment, there are many uncertain factors. However, in weather-dependent treatment such as the sun, the degree of dryness is difficult to control. It is easy to mix with miscellaneous odors during the sun exposure. At the same time, because the pulp has not been removed, it is prone to mildew and lack of stability.

Coffee Flavor: Ripe strawberry, blueberry, berry aromas or ripe fruit aromas, fermented wine aromas.

| water washing process

1. Bean selection

Place the harvested fruit in a tank of water and soak for about 24 hours.

Second, remove the flesh

The ripe fruit will sink, while the underripe and overripe fruit will float up and can be removed by machine to remove the skin and pulp, leaving only the coffee beans wrapped in the endocarp.

III. Fermentation

At this time, the outside of the beans there is a layer of mucosa, washing process is to wash this layer of mucosa and the adhesion of the mucosa is very strong, and not easy to remove, must be placed in the tank for about 18-36 hours, so that its fermentation, and decomposition of mucosa. There are two methods of fermentation, wet fermentation and dry fermentation, as the name suggests, the former with water, the latter without water. During fermentation, the seeds and inner pulp undergo special changes, which is one of the most important steps in washing coffee flavor. Farms that use water washing must build water washing tanks and be able to introduce an endless stream of fresh water. When processing, the fermented beans are put into the pool and moved back and forth, using the friction of the beans and the power of the running water to wash the coffee beans until smooth and clean.

IV. Washing

Finally, after washing, the beans are still wrapped in the endocarp, with a moisture content of 50%, and must be dried to reduce the moisture content to 12%, otherwise they will continue to mellow and rot. The better treatment is to use sunlight drying, although it takes 1 - 3 weeks, but the flavor is excellent and quite popular. In addition, some places use machine drying, which greatly shortens the processing time and makes the flavor inferior to sun-dried coffee.

V. Drying

The dried beans can then be stored in a warehouse or sent to a factory for shelling, removing the endocarp and silver coating.

This washing method can remove impurities (stones or garbage, etc.) and defective beans through each step, so the appearance from the raw beans is relatively consistent, generally regarded as high-quality coffee, the transaction price is higher than the natural drying method refined coffee beans, but the biggest disadvantage of washing coffee is that coffee beans are easily contaminated with the smell of fermentation during the fermentation process. If the beans are stained with fermented flavor, most of them are due to the lack of management and maintenance of the fermentation tank. Although the coffee beans with mucous membrane on the endocarp can be soaked in the fermentation tank for one night to remove the mucous membrane, if the microorganisms in the fermentation tank change, the coffee beans will be stained with fermented flavor. Moreover, the equipment cost of coffee washing method is relatively high, and the washing step is also quite time-consuming. The production cost is relatively increased, but due to water washing, the coffee quality is more stable.

Coffee Flavor: It retains the coffee flavor of a bean, which enhances the brightness of the coffee, that is, acidity, and special fruit.

| | half sun |

It is a method between sun exposure and water washing, which can be divided into two categories: peeling and tanning and honey treatment. The two kinds of treatments are basically very similar, first, like washing treatment, removing the outer skin of coffee cherries, but skipping the process of "pool fermentation and rinsing with clean water" and directly drying in the sun. Although the methods seem to be similar, because of one of the important differences, there are two very different flavors, which are worth explaining separately.

This treatment uses much less water than the water washing method, and some of it is similar to the water washing treatment (removing the peel and pulp) and some is similar to the sun treatment (without fermentation in the pool), so it is also known as the semi-washing method (semi-washed method).

| Wet planing method

I. screening

Peel the coffee fruit, put the shell beans into a vat or sink filled with water, and remove the defective shell beans floating on the liquid surface.

2. Fermentation

Wash the dense shell beans that have sunk to the bottom of the water, put them in a bucket or plastic bag, and do dry body fermentation, that is, to ferment and flavor the pectin sugar on the surface of the seed shell. Basically, the longer the fermentation time, the more sour. The fermentation time varies from person to person, generally only a few hours, but some manors omit the dry body fermentation stage and directly expose the shell beans, which can always be sour and improve the sticky taste, so that the pectin sugar can be fully fermented to increase the flavor, usually between 12-36 hours, depending on the specific situation.

Third, shelling and drying

With shell beans exposed to the sun for one to two days, the moisture content of the bean body is up to 30% Mel 50%, and the bean body is still semi-hard and semi-soft. Wipe off the seed shell with a shell planer to speed up the drying process. After about two days, the moisture content of the beans reaches 12% Rue 13%. The coffee beans will be collected into woven bags, usually 40 kg and 80 kg each, and will be sent to the coffee processing plant for shelling, and the success will be completed in about four days.

The shelling process is to grind off the bean shell with a shell planer and then bask it in the sun until the moisture content reaches about 12% Murray 15%. The coffee beans are then sent for machine selection to remove a variety of impurities and then sorted by particle size.

However, the wet ploughing method also has some disadvantages, in the shell planing process, the coffee bean temperature will rise to 30-60 degrees, and completely destroy the parchment, which is likely to trigger the bean sprouting. And it will also occur because the peel is shaved off in the production process, and let the beans come into direct contact with the air, so defective beans such as moldy beans are much higher than washing and tanning.

The effect of early removal of the seed shell is that the raw beans are half dry without the last two layers of protection (note: the four layers of coffee beans: pericarp, pectin, seed shell, silver skin), which is like taking off your clothes and basking in the sun. Although the wet planing method solves the problem of drying time, the relative probability of raw beans contaminated by molds, fungi and yeasts is also greatly increased. Paradoxically, however, these factors have become the key factors in creating Manning's special aroma.

When it comes to wet ploughing, we have to mention sheep's hoof beans! If you look at Manning's raw beans, you will find that there are a lot of sheep's hoof beans. Because semi-hard and semi-soft wet raw beans are easily crushed by mechanical force when removing seed shells, beans are easy to crack like sheep's hoof, which is why there is a high ratio of sheep's hoof beans in Sumatra.

Coffee flavor: low acidity, relatively mellow, obvious caramel and fruit aromas, even with herbal or grass aromas and woody aromas.

| | Honey treatment |

Honey treatment process: the process of making raw beans by sun-drying with mucous membrane. After the outer pulp of the coffee bean is removed, there will be a layer of sticky jelly. In the traditional washing method, it will be washed away with clean water, but because of the water resources limitations of some high-altitude areas, this method of drying directly with pectin has been born.

Honey-treated coffee has higher sweetness, higher sugar content and higher alcohol thickness than washed coffee. (only if the same baking degree is compared)

According to the thickness of pectin planing, the length of sunshine time (or drying thickness), and the frequency of turning when drying, honey treatment can be divided into black honey, red honey, orange honey, yellow honey and white honey.

According to the thickness of the pectin:

Black honey: hardly removes pectin, so it takes the longest time to dry and lasts for more than 14 days. In order to avoid drying too fast, cover will be used to block too strong sunlight to make sugar conversion more fully.

Red honey: remove 25% pectin (the specific methods of each manor vary), the sun lasts for about 12 days, and shading sheds may also be used in the process.

Yellow honey: remove 40% pectin and receive maximum light drying for about 8 days.

Some producing areas and estates are distinguished according to the drying thickness and the number of turns, such as yellow honey and white honey, both retain 20-30% pectin:

Yellow honey: thick layer drying, less turning times, long drying time

White honey: thin layer drying, more turning times, short drying time.

Coffee flavor: retains the cleanliness of the washing method, although not as bright as the washing treatment, but increases the sweetness and caramel taste.

| Kenyan 72-hour fermentation water washing treatment

Originated in Kenya, the cycle repeated treatment method of washing after fermentation was adopted to select the best quality cherries for peeling and fermentation. the fermentation time was 24 hours and washed with clean river water after 24 hours. Then, it is fermented again with clean river water for 24 hours, then washed, and repeated 3 times to reach 72 hours, so it is called Kenyan 72-hour fermentation water washing treatment, referred to as [K72].

Specific process:

First washing and fermentation

After the high-quality and ripe fruits are selected, the peel is removed, washed and soaked, and the pectin mucus attached to the outer layer of raw beans is fermented. Pectin has natural sugars and alcohols, which play an important role in the development of sweetness, acidity and overall flavor of coffee. The fermentation time is as long as 24 hours. after fermentation, 80-90% of the pectin can be removed, leaving only the flavor in the coffee beans.

The second washing and fermentation

Then enter the second washing fermentation process, the coffee beans in the previous stage are washed and soaked in water for 24-48 hours. This process increases proteins and amino acids, and the acidity of coffee beans creates complex and delicate layers of taste. Finally, remove all remaining pectin and move the coffee beans to a high shelf for sun drying.

For up to 24 hours, 80% of the pectin is removed after fermentation, leaving only the flavor in the coffee beans.

Finally, remove all the remaining pectin and move the coffee beans to a high scaffolding for sun drying, depending on the weather, which usually takes about 10 days.

Coffee flavor: strong acidity, delicate layering, bright, clean but full flavor of beans.

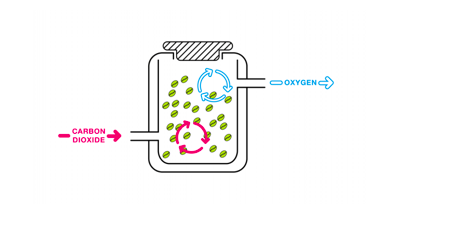

| anaerobic fermentation treatment

Anaerobic (Anaerobic) fermentation is a very popular post-processing method in recent years. Coffee fruit is usually fermented in water by placing the coffee fruit in an airtight container or in a washing tank. In this process, different microorganisms are used to ferment to produce a special flavor.

The first time I heard about anaerobic fermentation was in the 15-year WBC competition, an anaerobic fermented bean from Sasa Sestic, Australia. The reference bean of SASA injected carbon dioxide into a sealed fermentor and discharged oxygen from it. In an anaerobic environment, it slowed down the decomposition rate of sugar in pectin and mucus of coffee, and the PH value decreased more slowly, the fermentation time was longer, the taste of coffee was more round, and the cleanliness was lower than that of aerobic fermentation. The thicker the alcohol, the more malic acid / tartaric acid.

The characteristics of this anaerobic treatment are as follows:

1. There must be a completely closed opaque container that can be monitored.

2. then seal the container, fermentation is actually a process of converting sugar into a variety of compounds to produce alcohol and carbon dioxide, resulting in high pressure in the sealed container, and high pressure is beneficial for seeds to absorb flavor substances in pectin.

3. The container is placed indoors, and the indoor temperature should be strictly controlled. The degree of fermentation of the container can be controlled by controlling temperature and time.

4. Finally, carbon dioxide is continuously injected into the container to discharge oxygen. In the process of fermentation, PH value is an important reference index in the fermentation process. It is necessary to strictly control the change of temperature and PH value. When the sugar in pectin and mucus has just been completely consumed, immediately open the seal to stop fermentation, and immediately dry in the sun to avoid excessive fermentation.

Coffee flavor: with fuller mellow thickness, bright aroma, low acidity and better sweetness.

| Red wine treatment

Red wine treatment, also known as carbon dioxide impregnation, is inspired by the brewing technology of red wine. different from the traditional process of pressing grapes and fermenting wine, it puts the whole bunch of red grapes directly into an airtight container full of CO2, and finally gets a red wine with light color, strong fruit aroma and excellent taste after slow anaerobic fermentation.

The concept of this process is introduced into the coffee treatment process, and the peel of the coffee bean is removed and put into a stainless steel container filled with carbon dioxide and oxygen in the fermentor, thus creating a closed and anaerobic environment, so that the coffee fruit undergoes strictly controlled anaerobic fermentation, thus developing more aroma and high-quality sour taste of the coffee.

Coffee flavor: with strong fruit aroma, strong wine aroma and high quality fruit acid.

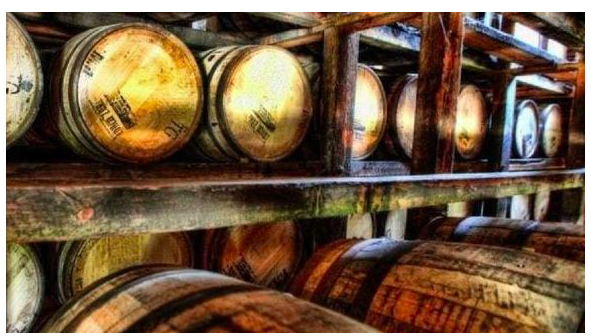

| | Shirley barrel fermentation treatment of fine washed whisky |

"Sherry barrel" is used as an aging barrel by the Sherry winery in the whisky industry. Sherry is a famous fortified wine produced in the sunny Jerez region of southern Spain. Sherry must be aged through the Solera system (Solera System) in the process of making sherry.

Solera system essentially refers to the process of mixing sherry of different ages after sherry is fortified. In the Solera system, all the barrels are stacked according to the vintage, with the oldest sherry at the bottom and the youngest sherry at the top, extracting some of the wine from the bottom barrel each year for bottling and sales, and then extracting the appropriate proportion from the upper barrel to replenish it.

The exquisite washing Shirley bucket fermentation method is to first carry out the delicate washing treatment of the picked coffee cherries, then put the processed coffee cherries into the whisky-ripe sherry buckets and ferment at a low temperature of about 15-20 ℃ for 30-40 days, and then dry them in the shade.

Coffee flavor: it has amazing aroma, thick taste and strong aroma of wine.

| | treatment of raisin honey |

Costa Rican musicians' series of raisin honey treatment is to retain 100% pectin and zero water treatment. In general, the fresh coffee fruit is harvested without removing the peel, directly placed on the drying bed and dried into a raisin state. Then remove the peel and retain the pectin before drying. At this stage, climatic factors are the key to the success of honey treatment.

Keep turning these coffee cherries during the drying process to make them dry evenly, but control the turning frequency and dry slowly to ensure that the coffee is fermented, but not so slowly that it is overfermented.

Coffee flavor: with the aroma of white wine and more balanced fruit acid, the fermented aroma is relatively rich and obvious and the finish is full of sweetness.

| Lactic acid fermentation method

Lactic acid fermentation is to obtain higher concentration of lactic acid bacteria in the process of coffee fermentation by anaerobic method. Because the ideal flavor of coffee is "mellow", "high sweetness", "caramel", "wine acidity" and "silky taste", all of which depend on the concentration of lactic acid in the fermentation process.

Before you begin to remove the peel, put the cherries in an airtight jar. Record the sugar content, temperature and pH value; ripe cherries have a high sugar content, and they provide sufficient food and fermentation for yeast and bacteria that naturally exist in the air and coffee cherries.

One of the by-products of the fermentation is carbon dioxide, which is slowly filled with carbon dioxide when the jar is sealed, draining the air. Under these anaerobic conditions (that is, no oxygen), the living bacteria produce lactic acid, hence the name. After lactic acid fermentation, LPET will ferment the coffee cherries in a container for about 70 hours before removing the peel.

If you want to know whether coffee cherries have undergone lactic acid fermentation, the easiest way is to look at the beans after removing the peel and pulp. If all goes well, some of the colors in the pulp will be transferred to the beans because a little alcohol will be produced during the fermentation process.

After drying, these raw coffee beans still need to be manually screened before they can be exported. In the final screening process, the ratio of raw coffee beans to coffee cherries was about 1:85, which means that LPET needs an average of 85 kilograms of coffee cherries to produce 10 kilograms of raw beans.

Coffee flavor: the overall taste is mellow, with aromas of caramel and wine, full-bodied and smooth.

| fermentation in vivo

The method of fermentation in animals is a relatively cruel method of coffee treatment. the most typical is civet coffee (Kopi Luwak). Civets often come out at night, relying on their eyesight and sense of smell, specially selecting the most mature and reddest coffee cherry fruits to eat. the indigestible coffee beans are excreted from the body through feces, and these precious internal fermented beans are obtained after cleaning and processing.

This treatment uses lactic acid bacteria and digestive juices from the animal digestive tract instead of machine or water washing to remove the pectin from the pulp and pods, which also doubles the flavor of coffee and has its own unique fermented taste.

Coffee flavor: has a unique fermented taste, mellow taste, partial nutty belt, chocolate.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

How long does it take to soak and extract in the smart cup? What is the smart cup suitable for cooking with coffee beans? flavor and taste characteristics

Today, let's talk about that beginners can easily get started, and they can easily make themselves a good cup of coffee at home. It is one of the necessary coffee brewing utensils at home. The smart cup is simple, convenient and easy to use. it is extracted by soaking without much skill. it can reduce mistakes in brewing techniques and make coffee flavor.

- Next

Let's enjoy the coffee producing area of Colombia!

People who like to drink single beans like to drink Colombian coffee very much. Super Colombian coffee has a rich and thick aroma. It does not taste as strong as Brazilian coffee, nor does it have an obvious sour tone like African coffee. But with clear high-quality acidity, high balance, sometimes nutty, memorable, no matter in appearance, quality, Colombian super

Related

- Can I make coffee a second time in an Italian hand-brewed mocha pot? Why can't coffee be brewed several times like tea leaves?

- Hand-brewed coffee flows with a knife and a tornado. How to brew it? What is the proportion of grinding water and water temperature divided into?

- What is the difference between Indonesian Sumatra Mantinin coffee and gold Mantinin? How to distinguish between real and fake golden Mantelin coffee?

- What does bypass mean in coffee? Why can hand-brewed coffee and water make it better?

- Unexpected! Ruixing Telunsu lattes use a smoothie machine to foam milk?!

- % Arabia's first store in Henan opens into the village?! Netizen: Thought it was P's

- Does an authentic standard mocha coffee recipe use chocolate sauce or powder? Mocha Latte/Dirty Coffee/Salty Mocha Coffee Recipe Share!

- What is the difference between Vietnam egg coffee and Norway egg coffee? Hand-brewed single product coffee filter paper filter cloth filter flat solution!

- What is the difference between sun-cured and honey-treated coffee? What are the differences in the flavor characteristics of sun-honey coffee?

- How to make Italian latte! How much milk does a standard latte use/what should the ratio of coffee to milk be?