Professional coffee roasting | what fragrance is added by "burning and increasing fragrance"?

Professional barista communication, please pay attention to coffee workshop (Weixin Official Accounts cafe_style)

Since the establishment of this text space, most of the ideas played by foreigners, the baking rhythm of foreigners, especially Home-barista, Nordic Forum, Scott Rao, Rob Hoos, Cafeculture, WCRC or German SCAE competition, etc., for no other reason, information is open enough, empirical easy, on the contrary, domestic related information is closed, willing to share publicly rare, Shao teacher's blog is the top of the emphasis on sharing, personal benefit.

Before the individual by Shao teacher "coffee flavor and baking time thinking" this masterpiece, extended to the "ignition" this method to make some discussion "I see Mena reaction period ignition effect", now look back, at that time I still feel that there are doubts, did not fully get the answer, it is necessary to use the current concept, think again, for example, the result of ignition bean temperature rise per second is not affected, but the furnace temperature rise per second increased by 43%, and, It's better to cook in a fast cooker.

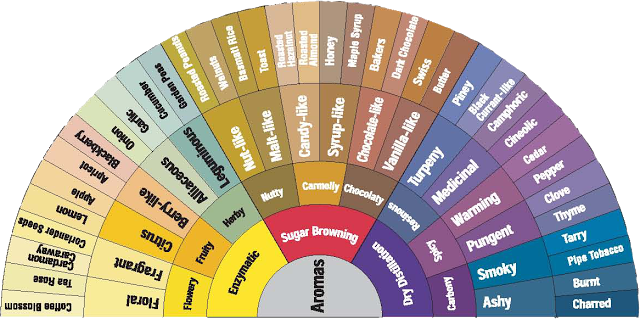

Before discussing the method of ignition, let's first define the purpose of ignition is to increase the aroma of coffee, but what aroma is it to increase? Think of the fast cooking stove is more fragrant this matter, fat fragrance, caramel fragrance immediately emerge, whether the two can be so related? The easiest way to explore coffee aroma is to go back to the old version of the flavor wheel, which divides aroma into three categories: enzymatic (enzymatic, floral, fruity, herbaceous), caramelized (sugar browning, nuts, caramel, cocoa), dry distillation (dry distillation, resin, spices, carbon incense), among which enzyme aroma, molecular weight is small, appears early, volatile, after a burst of development temperature is too high for too long, it is easy to burn it out; caramelization aroma, molecular weight is medium, a large number of development before and after a burst, but accompanied by caramelization process will also produce a large number of acids, aroma development and sour degradation is the main topic; Dry distillation aroma, the largest component, caramelized to a certain extent will enter the dry distillation reaction, it can remove the herbal astringency of coffee, but also generate bitterness and deepen the color of coffee.

Nordic baking method, no fire, fire from large to small adjustment, pay attention to the enzyme aroma, and sour and sweet balance, it caramelization and dry distillation reaction degree is relatively low, so the requirements for the quality of raw beans are relatively specific, how to bake a sour and sweet balance and no light baking often bitter feeling, is the basic requirements of Nordic baking, and the use of a large number of hot air to create fruit bomb-like aroma, is its enzyme aroma further emphasized operating guidelines. Therefore, purely on logical reasoning, the object of fire enhancement should not be the small molecular weight aroma of enzymes, nor is it likely to be the high molecular weight aroma of dry distillation, unless someone wants to create the flavor of charcoal coffee. Therefore, we should focus on caramelized aromas.

One of the few books on the market where a store openly explains its baking tools and baking curves

We know, of course, that the numbers on the baking curve are meaningless if you change machines, so these famous stores should not worry about the problem of flavor reproduction and customer loss. The baking machines used in the book, direct fire, semi-hot air, hot air all occupy a considerable proportion, each store open furnace times are different, there are a total of 26 stoves, of which the hot air machine accounts for 7 stoves, the remaining 19 stoves, whether it is direct fire or semi-hot air, between the beans into the explosion of the operator has increased the firepower accounted for 4 stoves, the remaining 15 stoves or take the firepower from large to small way of operation. Most of these 26 stoves were baked into the second explosion. In addition, the text in the book did not mention it. Therefore, it cannot be inferred that the operation mode of increasing the fire power in the middle is to promote incense. I posted 3 baking records for everyone's reference.

Direct fire baking, increase fire power after the yellow dot, reduce fire at the beginning of the first explosion, is one of the few baking books that does not enter the second explosion

Diedrich infrared semi-hot air, after browning beans shrink stage fire, a burst of fire again until the next beans do not drop fire, roaster self-evaluation to give excessive heat, forming a strong taste of coffee

Then adjust to the next table.

Diedrich infrared semi-hot air, after browning beans shrink stage, 28 seconds after the first explosion again until the next beans do not reduce the fire, baking self-evaluation because of the temperature increased by 5 degrees, the overall baking time shortened by 10 seconds, the flavor is ideal

This book was placed at the bedside. I flipped through it N times. Except for the hot air fan, I could not prove it, the firepower and damper configuration of the other direct fire and semi-hot air could almost be summarized into a truth. Most of the books do not make fire action to increase the fire power, even if there is a middle fire, the purpose is not to increase incense, or similar to frying incense with high fire in a fast furnace.

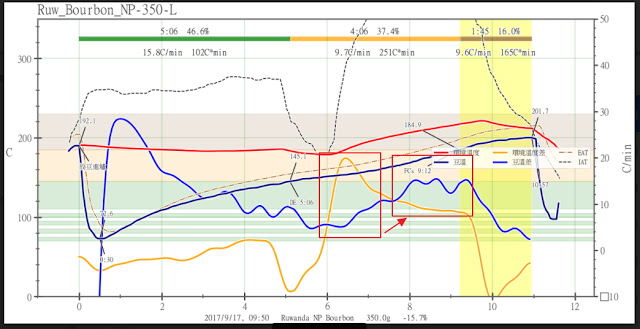

Returning to the ignition effect discussed earlier by quoting Teacher Shao's masterpiece, it only affects the furnace temperature but not the bean temperature. I think there will be blind spots in calculating the heating rate by averaging. It is better to turn on Artisan and take samples every 3 seconds to observe the changes of furnace temperature and bean temperature RoR. My inference is that in the same time section, the ignition has an effect on the furnace temperature but has no effect on the bean temperature. Perhaps it is because it takes time for the change of furnace temperature to react to the change of bean temperature, and the length of this time varies according to different machines. The observation comparison interval is extended, and not only compared with the same time section, it is better to have RoR curve comparison, and the influence of ignition on bean temperature can be seen. Below is my curve, IAT changes due to the amount of ventilation for multiple adjustment has a large fluctuation do not look. The EAT curve is my 2nd bean-warming stick, don't look either. In the part of red frame, the environmental temperature difference rises rapidly due to the increase of fire power, but the reaction of bean temperature RoR is delayed by nearly 30 seconds, and when the effect of fire ignition on environmental temperature rise has stabilized, bean temperature RoR also reaches plateau period until after explosion.

If I look at my own curve, the point of ignition is about 160 degrees in the yellow point, and the role of ignition is to play a browning at 175 degrees to 185 degrees, which is equivalent to the beginning of caramelization to enter the peak stage. The beans baked in this way, as long as the fire after explosion, as well as the control of the next bean point, caramel fragrance is very sufficient, sour to melt and sweet fragrance are also quite in place.

If you ask me where it is better to ignite the fire, or whether to lower the fire after igniting the fire, or to lower the fire at that point, I dare not say anything, but there is a direction you can think about.

The purpose of reducing the fire before and after the explosion is to make the beans, which are relatively dry and fragile, do not heat up rapidly and cause scorching under the condition of exothermic reaction, so if your ignition point is very close to the explosion, where will the ignition effect occur? Will it be the point where the beans need to reduce the fire? Also, if you only push the fire, for example, 10 seconds, 20 seconds, and then restore the fire, although it depends on the machine, I think that operation will only increase the instability of the baking environment, which may affect a part of the pot of beans. If this instability is what you want, it is not a problem to create a unique flavor.

Therefore, if I want to use the ignition method, I should increase the fire at the point where the beans turn yellow. How much fire should be added depends on the change of RoR of the bean temperature. For example, I hope that the RoR at the time of the first explosion is between 8.5 and 10.5, so that my development time can be extended to 2 minutes without obvious flick or stall problems.

In principle, the baking method of ignition is classified as Slow Start Fast Finish(SSFF) baking rhythm, and the RoR is pulled open in the middle with a larger fire power to highlight the level of fragrance, but it will be a pity for those who like enzyme action aroma. But isn't baking beans a choice?

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Why are Ethiopian coffee beans always big and small? Is there any difference in flavor?

For professional baristas, please follow question 1 of the coffee workshop (official Wechat account cafe_style): why are Ethiopian coffee beans always big and small? If you are very fond of African beans, it should be easy to find that Ethiopian beans are generally of different sizes and have significantly lower evenness than those in Kenya. Whether it's Yega Sheffield or Sidamo,

- Next

Practical paste of coffee grounds | how to effectively dry coffee grounds

Professional barista communication please follow the coffee workshop (Wechat official account cafe_style) do you know? In fact, coffee grounds can help us solve many small problems in life, and there are many wonderful uses. But first, complete a very important step to dry the coffee grounds. Because if you use the coffee grounds directly without completely removing the moisture from the coffee grounds, the coffee grounds will be sent first before you see the effect.

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?