Professional coffee roasting| Double Bake, Light Bake, Nordic Bake

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

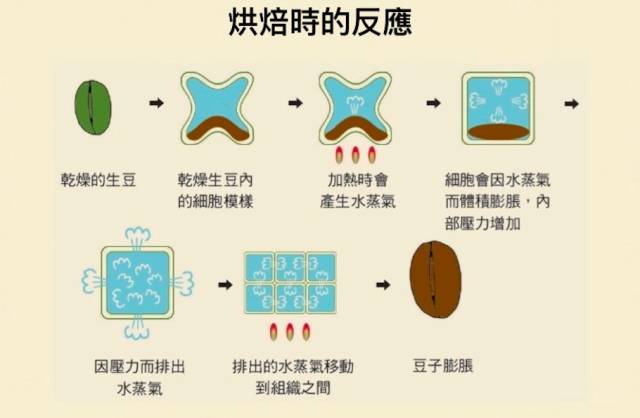

The roasting of raw coffee beans is a very technical work. In the process from raw to ripe, raw beans gradually lose moisture, swell, browning, Maillard reaction, caramelization and other changes, in order to better show the original regional flavor of coffee.

Caramel reaction [coffee roasting | caramelization]

The sugar in the coffee bean is caramelized at about 170-200 ℃, which is exactly the melting point of sucrose (185 ℃) and the temperature of the explosion stage when the coffee bean is roasted. The product of caramelization is divided into two parts:

In general, the aroma, caramel and color of the caramel reaction are produced, as well as other aromatic substances such as maltol, Cyclotene, furan compounds, etc., which can also be found in red wine, fruit juices, cream and other foods.

However, if caramel is too much in the baking process is not a good thing, but will cause carbonization, making the coffee dry and choking. If the caramel is not enough, it will make the aroma monotonous and lack of layers.

Mena reaction

Mena reaction refers to amino acids and reducing sugars (glucose, fructose, lactose, etc.) in food. ) A series of reactions in the heating process. Mena reaction produces a variety of aromatic substances and pigments such as Pyridines, Pyrazines, Oxazoles, Thiazoles, Pyrroles. The Mena reaction plays an important role in the flavor of food cooking, whether it is the blackening and fragrance of the sausage when baking sausages, the soft roast chicken on the outside and the delicious baked bread. Mena reaction is responsible for the complete color, smell and flavor of these barbecue foods.

Among these many baking methods, we specially pick out "double baking", "small fire baking" and "fire baking" to introduce to you.

Double baking

Let's start with "double baking". Some people call it "secondary baking". Literally, we can clearly explain that when baking beans for the first time, we use low heat to bake beans until the moisture begins to decrease, when the beans become lighter, and when the beans are dehydrated, stop baking. The beans taken out must be completely cooled (usually for up to a day) and make sure that the "bean heart" has cooled completely before proceeding with the second baking.

However, you may ask, why do "double baking (secondary baking)"?

This can be divided into appearance and taste of beans to show that through "double baking (secondary baking)", the moisture of beans can be removed first to avoid uneven baking. in addition, in this way, the appearance of beans will be more consistent and consistent, if for the seller of baked beans, it can make the baked beans more beautiful. But I think what is more important is that through "double baking (secondary baking)", astringent taste can be removed, excessive aroma and flavor in some beans with different characteristics can be suppressed, and taste balance and stability can be achieved.

Of course, most of us carry out "double baking (secondary baking)" because of the latter, but we also know that during the roasting process of raw coffee beans, with the increase of baking time, the aromatic substances are also produced and then gradually disappear, so how to take into account the above characteristics, to achieve a balance point is even more a knowledge.

Under all the same conditions, the coffee liquid extracted from "double roasting (secondary baking)" beans shows obvious relative calm and balanced taste, and there will be no "too much" unnecessary aroma and too prominent flavor. For drinkers who like to taste docile and smooth and homogeneous, there is no doubt that "double baking (secondary baking)" is the best baking method, on the contrary. The coffee liquid extracted from non-"double roasting (secondary baking)" beans is more lively and full of vitality, with rich changes in bitterness and sweetness at the same time.

Thin fire baking

In addition, "small fire baking" is also known as "long-time baking", and the vernacular point is "slow fire pie." this baking method is handled properly and can be skillfully adjusted to increase bitterness. for some drinkers who like bitter taste, it is also possible to boldly choose beans that are "suitable" for shallow baking in this way, which is really a great blessing! However, it should be specially emphasized that this does not mean that beans baked in the way of "thin fire baking" will not be sour, but "increase bitterness"!

Now that we mention "small fire baking", let's also say "fire baking", that is, "fast fire pie" to shorten the baking time. This baking method is operated properly, and it can also skillfully adjust the sour taste, remove unnecessary residual sour taste, and leave a wonderful and lively sour taste, but because the baking temperature is higher, it will be easier to bake unevenly or have excessive smoke smell. However, these two situations can still be solved through the adjustment of baking skills.

As mentioned by Taguchi in the Collection of Fine Coffee, the most suitable roasting degree for Ethiopia's Yega Xuefei in category c coffee is medium depth, which is also in line with what he said in systematic Coffee that thick, fleshy coffee beans from medium and high producing areas are suitable for "thin fire roasting".

According to the information guide of Japanese coffee master Taguchi: on April 7, 2012, 253 grams of Yejiaxuefei were baked, half a minute after the second explosion, French baked beans, defective beans 0.5%, cooked beans 202 grams, dehydration rate 19.8%.

First of all, the stove is heated to 200 degrees, the cease-fire and other stoves are cooled to more than 150 degrees, and then re-ignited and blanked; the beans are preheated for 6 minutes and 46 seconds; to 180 degrees, complete dehydration; to 199 degrees, an explosion starts at about 12 minutes 36 seconds; to 203 degrees, an explosion is dense, 208 degrees is completely over, 14 minutes and 40 seconds; the second explosion starts at 19 minutes, ends at 222 degrees, 22 minutes 40 seconds, and then stops for 40 seconds, 23 minutes 20 seconds.

The beans are brown and black.

Nordic baking

With regard to Nordic baking, that is, "fire baking", the problem of shallow baking is not only that the baking degree is set in the explosion (usually the time to drop beans can not be separated from the explosion), there are many other factors that are quite noteworthy, such as the change of firepower, the total time of baking, temperature and humidity, throttle control, and so on.

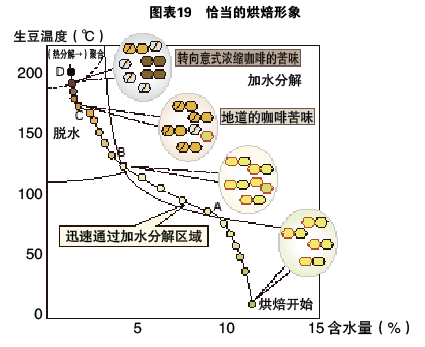

Although shallow baking (or very shallow baking) sweet and sour shock, sour beauty, sweet charm is one of the baking goals, but it often brings uncomfortable acid at the same time, usually from the above changes due to lack of mastery. As a result, the built-in acid degradation and development of chlorogenic acid, citric acid, malic acid and so on are incomplete. Or the poor mastery of caramelization reaction and the incomplete reaction of Mena lead to the feeling of sweet powder. These marginal baking methods are easy to screw up because of these troublesome chemical changes. As a result, long-term bean cultivation and cooked achievements have become the only solution.

Excerpt from the new version of coffee science, although Nordic baking is a very shallow baking style, it is "shallow roasting without hurry or slow". The control of firepower is simply a big fire until before the explosion, reduce or turn off the fire to glide, so that the important stage of the explosion is not urgent and complete caramelization, Mena reaction, and the fire before the explosion with the fully open throttle, let the hot air play its due effect. As a result, even if the beans are dense or even before an explosion, the acid has its complete degradation time.

Another key is the time to turn off the fire or set it to a very small fire. I'm afraid it depends on the lock temperature parameters of the roaster. In any case, there should be enough thrust to let the temperature rise slightly and slowly reach the target of a burst.

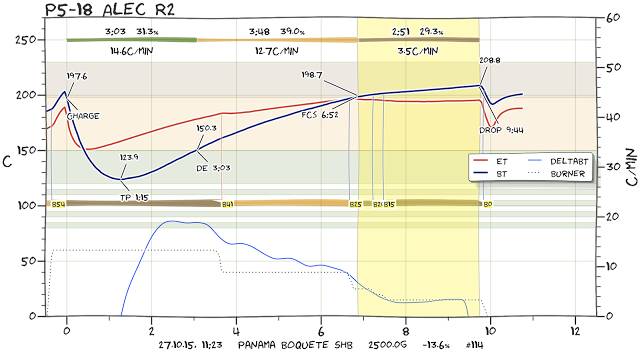

For example, the curve of a ProbatOne 5Kg bean roaster using a fixed throttle in the German 2015 SCAE Baking Competition.

The initial firepower of ALEC is 60%. With this firepower and a fixed exhaust air volume, the RoR can reach 18 degrees per minute. After the dehydration stage is completed, the firepower is reduced to 40% and the ROR is also significantly reduced. Before the explosion, the firepower is reduced to 30%. At this time, the bean temperature begins to exceed the exhaust temperature (ET), indicating that under the combination of 30% firepower and a fixed exhaust air volume, the inlet air temperature is lower than the furnace temperature, and the heat energy is transferred. It has changed from hot air to the conduction of baking buckets and the radiant heat of beans into exothermic reactions. the function of ventilation is to remove smoke and dust, and to slow down the heating rate of beans during the development period.

In the end, the firepower dropped to only 20%, and the bean temperature was further apart from the discharge temperature. This is the champion curve that bakers make good use of ProbatOne, which uses thick cast iron pans and emphasizes that hot air accounts for 70% of the machine's efficiency.

[moderate baking bitterness] and [deep baking bitterness]

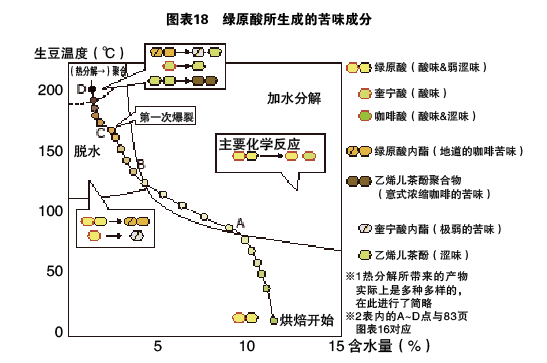

"the bitterness of coffee is roughly divided into two types. That is, 'moderate baking bitterness' and 'deep baking bitterness'.

The chlorogenic acid lactone produced by chlorogenic acid is moderately baked bitterness, and the vinyl catechol polymer produced by caffeic acid is deeply baked bitter taste, which is a kind of bitterness with scorched and bitter taste. The coffee baked by moderate roasting with failed moisture removal will be very astringent, and if it is further roasted into deep roasting, it will produce a more pungent bitter taste and become a slightly stronger flavor than astringency. Therefore, is it true that everyone has taken the name of Deep Bakery School? "

Photo source: Taguchi, coffee formula

Summary

① moderate baking bitterness (chlorogenic acid lactone)

② deeply baked bitterness (vinyl catechol oligomer).

① is the so-called "authentic bitter coffee."

② is the bitterness of deep-roasted coffee such as espresso.

Therefore, medium and deep baking is an intermediate flavor between ① and ②.

The bitter taste of ① is mild, and people who are afraid of bitterness can easily accept it. If the roasting is medium and deep, even if there is such a bitter taste, some people will still think that "this coffee is not bitter at all and easy to drink." Having said that, since bitterness is bitter after all, it will still be unbearable if it is too strong.

When most of the ② is combined, it becomes a "vinyl catechol polymer" (bitter taste), which is defined here as a "bad scorched taste".

② 's vinyl catechol oligomer may be just one step away from the "bad charred smell".

Photo source: Taguchi, coffee formula

To explore roasting from a scientific point of view, if the moisture is not cleverly removed during baking, the roasted coffee is sandwiched bitter coffee. On the contrary, if the water can be removed well, the dehydration reaction will be accelerated, resulting in a "authentic bitter taste of coffee", coffee will taste better.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

How long after the coffee beans are roasted, can you still drink the coffee that expires?

Communication of professional baristas Please pay attention to the shelf life of coffee beans in the coffee workshop (Wechat official account cafe_style): generally, the shelf life of coffee beans is as long as two years, only properly preserved, the shelf life can be extended. But if the coffee beans are damp, they will quickly go bad. Generally speaking, it won't do much harm to quote a small amount of expired coffee, but if you find coffee beans

- Next

Practice beans for the treatment of expired coffee beans

Professional barista communication Please pay attention to the coffee workshop (Wechat official account cafe_style) the simplest thing is to use it as practice beans, to practice hand flushing, siphon and Italian style, which can also be used for cleaning: grind expired coffee beans into powder, scrub copper products and polish the floor; wrap ground coffee powder in gauze and wipe the stove and pot lid for effective decontamination

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?