Professional coffee roasting | how to bake coffee with delicate flavor?

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

To write this topic is not to declare that I can do it personally, but to adhere to the principle of be humble and open mind and once again review the master's exposition, and at the same time find some phenomena that I have observed and confirm each other.

Main quote: "The Flick" created by Scott Rao 08Accord 04 Universe 2015

The "flick" at the end of the roast causes the charred flavor and loss of delicacy. The flick indicates an acceleration in the bean ROR. Several factors may contribute to a flick, including a "crash" in the ROR early in first crack, drying of the beans, and overheating of the roasting environment. The most damaging cause is an increase in the roasting drum's surface temperature.

Is it beside the point to quote Scott Rao "The Flick"? In fact, this is a kind of logical reasoning. According to Scott Rao, if a pot has "crash" and "flick" before the end of the baking, especially "flick", the coffee will lose its meticulous delicacy, even with a scorching flavor. Therefore, if you want to bake the delicate flavor of coffee, first, add the bean temperature warming curve (RoR) to your baking monitor, not just watching, listening and smelling; second, set to rule out the "crash" and "flick" phenomena in the roasting process.

There are several reasons for "flick", such as the process of drying and dehydration of beans, the overheating of the baking environment in the roaster, the increase in the surface temperature of the baking bucket, and the "crash" phenomenon at the beginning of an explosion. As for the effect of "flick" on bean flavor is compared, that is, Scott Rao believes that the same kind of beans, the same baking degree, the same baking rhythm, the pot that does not have the phenomenon of "flick" is more delicious and meticulous, and the pot that produces "flick" will even have the bad taste of overbaking, such as smoke and scorch.

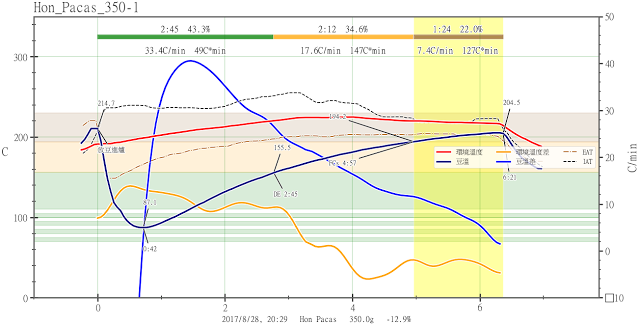

Let's look at the two pictures in the original text.

Figure 1, natural curve. Blue: bean temperature and bean temperature RoR; brown: ambient temperature and ambient temperature RoR (commonly known as RoC)

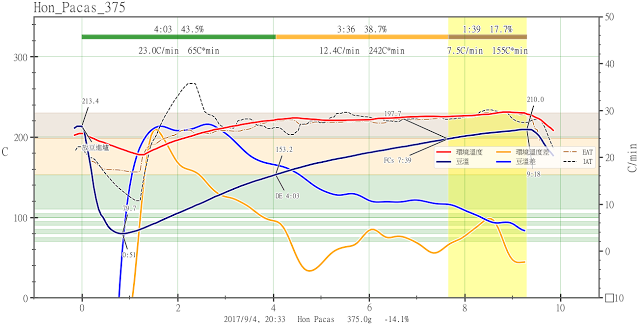

Figure 2, well-controlled bean temperature and RoR curve, which Scott Roa says is the curve recorded by the pot with the deepest memory and the best flavor he has ever drunk.

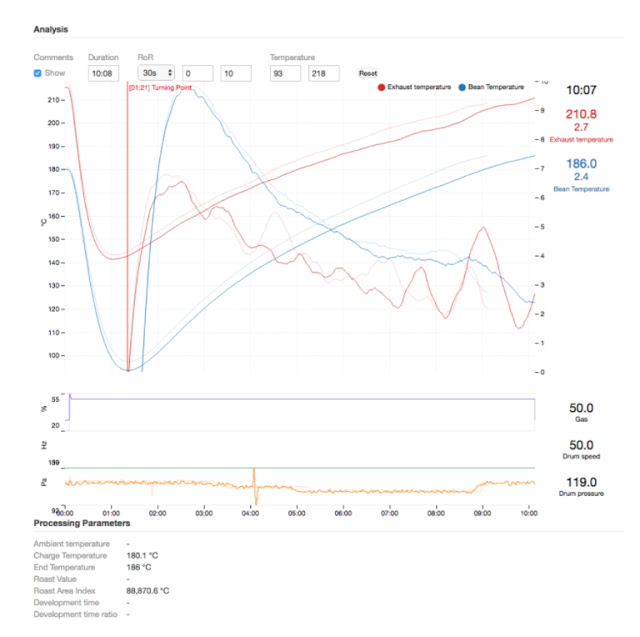

Why did you add RoR to the object of real-time monitoring in the first place? because you can't see the phenomenon mentioned by Scott Rao by just looking at the bean temperature curve or recording the bean temperature every 30 seconds, and connecting the temperature sensor to the computer is a basic requirement.

Figure 1. As soon as the explosion begins at 11:46, the bean temperature RoR drops sharply. This phenomenon is what Scott calls "Crash". A similar situation does not appear in the RoR curve of figure 2. Then, before figure 1 14:21 lowered the gas firepower, the bean temperature RoR climbed sharply at about 14: 00:00. This phenomenon is what Scott calls "Flick". At 14:21, it is too late to lower the firepower when the bean temperature rises too fast. The bean temperature RoR continues to rise sharply for about a minute. This phenomenon is also not seen in figure 2. After reaching the peak in nearly 3 minutes, the bean temperature RoR in figure 2 steadily slopes all the way to the right. It constitutes the most memorable and perfect flavor in Scott Rao's mind, and this curve has become a classic for him to convey the above ideas.

We know that another famous argument of Scott Rao is that DTR (Development Time Ratio: the proportion of time from the beginning of the explosion to the total baking time) is the best at 20: 25%. He said that many people reflected to him that when DTR falls in the range of 20: 25%, there will always be the smell of excessive baking, and when they spread out their curves, they will always find obvious Flick phenomenon. The scorched smell is caused by Flick. It is not caused by the relatively long DTR (in fact, it is more difficult to avoid Flick after lengthening the DTR). All of the roasters who were open-minded enough to stick with the higher DTRs while learning to smooth their RORs eventually f ound the roasted notes disappeared and their coffee was sweeter than it had ever been. (translating Scott Rao's words into vernacular means that as long as these people are open-minded and come to me to learn how to eliminate the Flick phenomenon, they will eventually find that not only will the bad flavors of DTR not appear, but their coffee will be sweeter than before.)

In a typical pot of baking at 10: 14 minutes, Flick usually appears 90 seconds and 120 seconds after the start of an explosion, so as long as you put in the beans before that, there will be no Flick phenomenon, and crash and flick will come out as time goes by. If the temperature sensing rod is too thick or the sampling interval is too long, it is not conducive to rule out the phenomenon of flick. If the temperature sensing rod is sensitive enough, the furnace temperature RoR will usually react earlier than the bean temperature RoR. For example, in figure 1, when the furnace temperature RoR rises between 12:00 and 13:00, measures can be taken in advance (such as reducing the fire, etc.).

This is the end of the original abstract. There are always believers, but of course there are plenty of unbelievers. In fact, the two pictures raised by Scott Rao are not drawn by the same software, and the completeness of the mark is also different, otherwise it will be more convincing.

One thing is certain, when the wind and fire is fixed, the phenomenon of crash and flick is a natural phenomenon, which will happen, no matter what kind of machine you are using. But how to avoid it depends on the characteristics of the individual machine, so Scott Rao will not and is unlikely to tell you a general method. What I'm interested in is how to avoid the "Crash" phenomenon. Let's take a look at some curves.

One of the 2016 WCRC championship curves, there is Crash, but the beans were dropped before the occurrence of Flick (fixed firepower only throttle)

One of the 2016 WCRC runner-up curves, RoR smoothing without Crash/flick

2015 SCAE German champion, crash is not obvious, no flick (throttle can not be adjusted, only firepower can be adjusted)

2015 SCAE German runner-up, no crash/flick (throttle can not be adjusted, only firepower)

Can you find out what they have in common? In the fire control mode of semi-hot fan (Giesen W6A, Probat 5Kg) with high hot air ratio and good temperature retention, Ramping is divided into stages. What should I do to my own machine?

Their own machine can only find their own answers!

My pot is a mess. Don't take it seriously.

When the article is finished, the only function is to rearrange the things in the head, and then the master's words are deliberated again, and there is still something to be done. After trying three pots, it can only be said that in principle, the direction I want is not wrong, low molecular weight, medium molecular weight, high molecular weight no matter in the cup test or cup test, the hand impulse presents a state of equilibrium, and all the empirical data are on the graph below. At present, what bothers my own machine is that the temperature is relatively unstable, and it will take more time to adjust this part.

Even if the development ratio reaches 25%, this pot is still sure that flick will not occur, because there is still room to reduce fire or increase ventilation.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Evaluate the standard of espresso and the skills of making espresso

Professional baristas Please follow the coffee workshop (Wechat official account cafe_style) We often hear customers complain that the coffee is too cold in the coffee shop. Customers walk into the coffee shop to experience the charm of the third wave of coffee and expect professional baristas to make them a cup of warm, fragrant coffee, but why do they have the idea that the coffee is too cold?

- Next

The difference between iced coffee and iced coffee distinguishes "iced coffee"

There is an essential difference between ice-drop coffee and ice-cold coffee. Ice-drop (or ice-brewed) coffee and ice-cold or ice-cold coffee seem to be different in one word, but they are essentially different in extraction and cannot be treated in the same way. Ice drop (also known as ice brew) coffee is a coffee beverage extracted by soaking in water below 5 degrees Celsius for a long time at a low temperature. Iced coffee or iced coffee refers to quick extraction with hot water

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?