Interesting baking curve (1) the problem of bean temperature and temperature recovery point

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

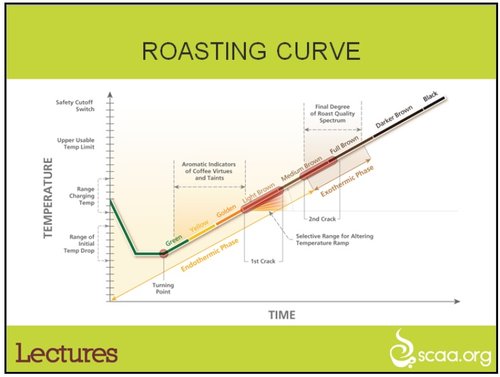

Rosting Curve

This picture is also Karl Schmidt, one of the slide of The Art & Science of Roasting. When I saw this baking curve, it immediately aroused a lot of feelings for me, because there are a lot of things to discuss, and I like it very much, so I share it with you here.

I wonder if you have carefully observed the changes in bean color during the process of roasting coffee, keeping records of bean temperature, stove temperature, throttle and firepower changes. The change in the color of beans during baking can tell us a lot of things. If we can understand it, it will be absolutely helpful to baking, even to the highest level. The ideal coffee can be baked by directly observing the condition of beans without using the data we measured.

There are three stages in the learning process of many things: the first stage is to see a mountain is a mountain, the second stage is to see a mountain is not a mountain, and the third stage is to see a mountain is still a mountain, and coffee baking is no exception. In terms of the learning process of roasting, it can be described like this: when you first step into the baking process or bake with a hand net, you don't understand where the beans are baked. However, on the one hand, the baking results are unstable, and on the other hand, success depends on accidentality. if you want to improve your stability and success rate, you have to use some instrument measurement parameters to help us, so some people begin to pay attention to the furnace temperature, bean temperature, firepower and so on. The baking presentation of beans becomes these data, and there is no comparative discussion on the state of beans. In my humble opinion, most people are still in the second stage. I am no exception.

Needless to say, everyone must want to enter the third stage, at this time, we have to put aside some of the shackles of data and return to the bean itself, which is the topic I want to discuss today.

Frankly speaking, this is a very "teaching book" baking area line, to be honest, he is not a big deal, but what I like is that he represents the various stages of the baking process in color, and these colors reflect the color and condition of coffee in each period. Let's start with the beans.

At the beginning of baking, the raw beans are thrown into the pot, the beans begin to be heated, and the bean temperature bar begins to drop until the temperature point (turning point), when the beans begin to be heated, the color is the color of the raw beans, so it is green, because the beans will not yet expand, the structure is relatively hard, and the sound is louder at this time.

As the beans are heated, the beans will expand and the volume will increase. At this time, I think it is very critical. At this time, it belongs to the steaming area. The purpose is to make the beans soft and expand. If the beans are slowly heated, you can observe the changes in the surface color of the beans, which will begin to fade from green (fadding, pale) and then expand to the whole bean to cause the bean to fade or turn white. Once you see this phenomenon, it means that the bean has softened, and the sound is not that crisp.

"this process, even if it is hard beans, there should be", but often hard beans directly from green to yellow. The result is easy to occur and lack of dehydration.

This process is critical because the structure of the beans affects the integrity of the subsequent dehydration.

But in practice, for M3 or small machines with less than 500 g, the temperature rise at this stage is about 14 Murray 15 degrees per minute. Because at this stage, the bean will absorb heat as much as it can. As long as the boiler stores heat enough, the bean will absorb it as quickly as possible until it reaches the temperature balance with him, but this speed is too fast for me now. This seems to be very helpless, because the small machine has few beans, so the beans are heated very quickly.

Beans are rolled and heated in the boiler, according to the index that beans can contact the unit area of the boiler wall, beans in small capacity boilers will enjoy more unit heating area than large pots, to put it simply, heating will heat up faster, at this time is just entering the beans, the effect of hot air is not yet significant, the heat source should be the heat conduction provided by the boiler wall. This will cause the beans to be heated quickly in a small capacity boiler, which is very troublesome, and the structure will not be soft enough if the temperature is heated too fast, but at this stage, for M3, it is not so fast to turn down the heat, and on the other hand, it may lead to the dilemma of losing temperature and not pulling up at the next stage.

(the only way I can think of is to increase the amount of beans or secondary steaming, and I hope to have the same idea to provide this area.)

As you can see, the difference between this picture and the curve of M3 near the temperature recovery point is that I probably have a V-shaped reversal, but it will turn again and again, or a U-shaped shape will be formed at the bottom. In the book "High-quality Baking Technology of famous Coffee shops in Japan," there are many baking curves that are passivated before and after the recovery point. It is worth mentioning that they all use large machines (mostly 5 kilograms). On the one hand, they roast a lot of beans, and on the other hand, the unit contact area of beans is smaller, so heating is slower than small computers. But they are the same, the firepower replenishment capacity of the large machine is enough, the big fire and big throttle can be corrected, the small machine is really very difficult.

In any case, once it is determined that the beans are white and soft, the silver skin will come off and moisture will come out, so it will usually open the throttle for about 1 minute to blow the silver skin and moisture, ready for the next stage.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Make your own coffee! Japanese coffee hand net baking!

Professional barista communication, please pay attention to coffee workshop (Weixin Official Accounts cafe_style) because 50+, but think of 90+ coffee. This is not about life after the age of 90, but Ninety plus (90+), which was founded in 2007. This company broke through the concept of traditional coffee hunters, not only collecting wholesale boutique manor beans, but further exploring coffee varieties and experimental planting methods.

- Next

Roast your own quality coffee beans. Master roasters teach you the secret of roasting.

Professional barista communication Please pay attention to coffee workshop (Weixin Official Accounts cafe_style) People who like desserts always want to make their own cakes. Similarly, people who like coffee will not be satisfied with buying ready-made coffee beans. Sometimes, so-called premium coffee in coffee shops has a bitter taste, or is infused with defective beans, which is very addictive. Sometimes you meet a great bean, but you're afraid to save it.

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?