Professional coffee roasting | difference and difference between semi-hot air baking and direct fire roasting

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style)

First of all, I would like to declare that this is my experience, and it is not objective, because very few people can change the core component of the bean baking machine [baking bucket] from semi-hot air to direct fire bucket under the same structure and system, and then make a comparison. This is not a conjecture, but my personal demonstration, and through the process and results of this demonstration, we can finally get rid of the framework of foreign arguments, after all, their foundation is based on hot air and semi-hot air, whether it is Scott Rao, Rob Hoos, Tim Wendelboe, Willem Boot, Joe Marocco, or the winners of WCRC, SCAE, etc., I try very hard to stand on their shoulders at a small price and thank them. Thanks to the borderless network, I have really gained a lot.

Once upon a time, I naively thought that when I bought a bean baker, there was no opening in the body of the baking bucket, so it could only be fed through the mesh at the bottom of the bucket. If the ventilation was not enough, I would change the fan to the fire row if I felt that the firepower was too weak, and the differential pressure meter would be used as an assistant. I have a semi-hot fan that can use hot air as the main source of baking heat. In fact, I just have a bean dryer that simply purifies the air into the baking bucket, which is still a long way from the degree of the semi-hot fan.

In the process, no one will tell me, nor have I seen you discuss related issues. after all, the machines that most people buy are completed, and for similar money, I don't even have a fire chop, and I have to assemble the DIY002 by myself, and the hidden DIY blood makes me fall in love with this machine as soon as I try it. I didn't even consider it, and I placed an order in the middle of the night that day. Also because they have been assembled many times, they are really familiar with the structure of their machines, adjust bit by bit, and carry out non-destructive transformations. as long as the baked beans are found in doubt, or well-founded discussion, they will find a way to prove it. until you confirm that your machine can achieve what kind of state of the semi-hot fan, what kind of furnace operation method can be used to achieve the goal you want to challenge.

After that stage, there is no hope for semi-hot fans, even for the world's top famous brands. After all, it is impossible for them to enter the coffee industry and do not need any machines that can stabilize mass production. It is time to study another more complex type of baking beans, that is, straight-fire baking.

In fact, every time you participate in a bug sharing meeting in Atti, you can drink bugs and other advanced straight-fire baked products, of which bug coffee is the most distinctive and highly recognizable, and that characteristic flavor, I call it [bug flavor], and bugs always say, that is the taste of straight-fire baking. The bug is good at using barrel speed at different stages to create the flavor of coffee. for a machine of 1 to 2 kilograms, the speed range can be changed from 10 to more than 100 revolutions per minute. If you add air conditioning and fire adjustment, the spectrum created is so large that it is hard to imagine. I often drink coffee with at least three flavor levels after the entrance. I personally try my best to use all the theories I have learned and try to get close to that level, but I have never reached it. Well, I can blame it that there must be a bug roaster to reach that level, because a lot of things cannot be simply summarized and restored. And in retrospect at this point, perhaps, straight fire is really an answer. Direct fire can do what semi-hot air cannot do, that is, the high-temperature heat of the flame, instantly heating part of the tissue of beans.

Putting aside the difficult theories such as Mena reaction, caramelization reaction and high temperature pyrolysis reaction, according to the experience of contact with food in daily life, the aroma and taste produced by high temperature barbecue are always the most prominent. For coffee, as long as you overcome three problems, direct fire baking will be because of its aroma and taste. Becoming an irreplaceable baking method (uniformity of the whole pot, scorching and overcooked endogenesis are three common defects in direct-fire baking).

The problem of the uniformity of the whole pot is caused by the improper design of the rotating speed of the drum and the mixing blade, the coke burning is caused by the rapid heating of firepower and fire when heating the drum and beans, and the endogenesis is caused by the rapid heating when the thermal energy intensity is higher than the thermal conductivity and thermal diffusion capacity of beans. All forms of bean dryers may have the above defects, but because the direct-fired bean dryers have the most direct fire source and the highest heat, it is most obvious that as long as there are structural defects (for example, the small machine also imitates the large machine fire row directly to the rolling bucket, or the drum blade group is too small, the speed is too slow), or the fire control is too careless, it is easy to destroy a pot of beans.

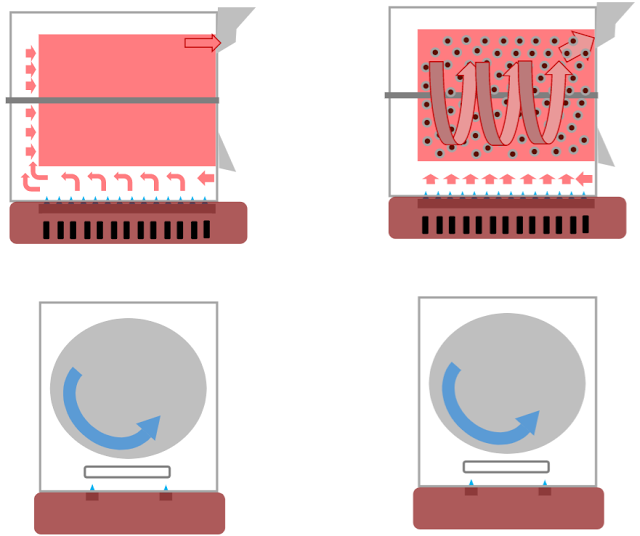

There is a picture of a semi-hot fan manuscript with a double-pot structure, which is suitable for discussing the straight-fire bean baking machine.

Indication of semi-hot fan for double-layer boiler body

In the picture above, in such a structure, the fire row can be heated to 350 degrees for the outer layer of the baking bucket and 260 degrees for the air about to be pumped into the baking bucket. because of the double-layer wall structure, the high temperature of the outer pot will not be transmitted directly to the inner pot, keeping the inner pot at a low temperature of 180 to 200 degrees, ensuring that the wall of the pot will not burn beans under any conditions, while ensuring that hot air is the main source of baked beans. Baking beans with uniform, stable, clean and consistent flavor is the design direction of the machine.

If the double-layer pot is replaced with a single-layer thin pot under the same mechanism, as shown below, the firepower of 260 degrees hot air will reach the high temperature of 350 degrees (where the beans are in direct contact). It is really difficult to estimate how much the whole baking rhythm will be improved. it may also produce charred, externally cooked and endogenous beans as a result of heating up too quickly. In order to avoid being too fast, the firepower can only be reduced, so the hot air temperature will decrease accordingly. In the same baking time, the proportion of hot air heat energy eaten by beans to the heat energy of the pot body and the machine of the double pot must be greatly reduced.

Semi-hot fan with single-layer boiler body

The semi-hot air pot with no hole in the barrel body has the above situation. What if the pot is replaced with a direct hot pot full of holes? On the one hand, we should consider the heat of the pot body, but also consider the heat of the flame acting directly on the beans. Where's the hot air? Under the same exhaust air volume, because the air intake area becomes larger, the wind speed into the baking bucket becomes softer, and because the whole barrel body has holes, and some even the bottom of the bucket has holes, the hot air entering the baking bucket simply comes from all directions, and the heat varies, so its hot air effect can not be observed by a single point of intake temperature, and the temperature of the hot air outlet is the only data that can be used for reference.

Back to the heat of the flame acting directly on the beans, it can heat the pot body to 350 degrees, obviously the temperature must exceed 350 degrees, and the effect on the beans is larger than the heating of the beans by the pot body (flame is a kind of high temperature hot gas, beans can be easily covered by convection). Therefore, in a comprehensive consideration, on the basis of the same amount of exhaust air, the hot air baked by direct fire is considered. It's completely different from semi-hot air. In my opinion, put it in the water vapor, smoke on the exclusion of consideration, if the drum speed can not be adjusted (but fast enough), as long as the mind on fire control.

The above is the corollary, and then there is the empirical evidence. The following picture is a schematic diagram of my semi-hot air and direct fire baking.

Left half hot air, right straight fire

I control the ventilation according to the reading of the differential pressure meter, in principle, because my semi-hot air structure can not use too much air flow, otherwise the pot will be too hot in order to make the intake air reach the required temperature. I always control the maximum wind pressure so that the size of the silver skin can be completely taken away as the upper limit. After changing to a straight hot pot, I still maintain the same wind pressure control. Because the fire platoon structure is the same, it can be concluded that under the same wind pressure and the same firepower, the inlet air temperature should also be similar (not the same can only be similar, because there is also the environmental temperature factor). The difference is that the wind speed of the direct fire acting on the beans is lower, and the inlet air temperature is different in different parts. According to the measurement, the wind temperature at the bottom of the beans can reach 475 degrees, while at that time the wind temperature close to the upper half is about 270 degrees. After heat exchange with the beans, the air outlet temperature is about 240 degrees, which is the biggest difference from the inlet air temperature of 270 degrees of semi-hot air and the exhaust air temperature of 240 degrees.

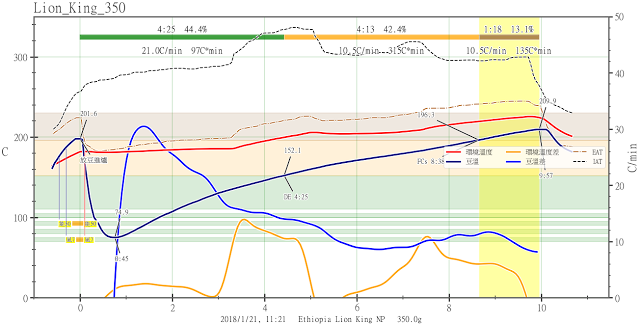

Semi-hot air structure baked Lion King

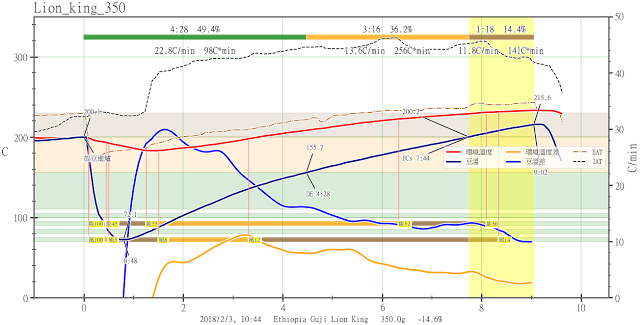

Direct Fire Architecture Baking Lion King

Take the same kind of beans (Ethiopian Guji Lion King Sun) respectively in the structure of semi-hot wind and straight fire, baking with similar rhythm and the same development time, the aroma of the straight fire is relatively strong, and the taste is relatively thick.

The direct fire because the heating is relatively direct, the impact of firepower adjustment on the curve is also very fast and direct, as long as the internal environment of the roaster is stable (does not change due to changes in the external environment), the exhaust air temperature goes according to the expected temperature, the wind and fire does not need to be adjusted. The heating mode of semi-hot air is more indirect. When the exhaust air temperature is found to be too low, the firepower is increased to increase the air temperature, but it is often found that the response is too slow or the effect is not as good as expected. Therefore, I compare baking a semi-hot hot pot to sailing, which requires a pre-reaction; a straight hot pot is like turning on a GO CART, but the reaction should not be too big.

My conclusion is that due to the high heating temperature of the beans, the aroma created by the direct fire is relatively strong, and because of the rapid response to rising and falling temperatures, after proficiency (for me), it is much more refreshing to bake, which is my experience at this stage.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Starting from Coffee cultivation-the upcoming planting and Environmental problems in Coffee growing areas in Yunnan

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) A coffee tree bears fruit several times a year. Coffee is one of the agricultural products, and its yield varies by region, climate, altitude, planting mode and other factors. From coffee sweeping the world to becoming the most popular drink in western countries, the whole world

- Next

Is there any difference between coffee or cafe' written at the door of the coffee shop? What does cafe mean?

Professional coffee knowledge exchange more coffee bean information Please follow the coffee workshop (Wechat official account cafe_style) this question has always been in my mind, obviously how some doors of coffee shops write Dou big Coffee, while others write Cafe? What's the difference? Of course, the generation on the Internet is looking for it with the search engine Google, with the keyword coff.

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?