What are the ways to handle coffee beans? Sun treatment and water washing treatment are introduced and compared in detail.

There are three traditional coffee bean treatment methods: sun treatment, water washing treatment and honey treatment. Honey treatment is between sun and water washing, whether it is the treatment method or taste, so today let's talk about the biggest difference between sun exposure and water washing.

A delicious coffee bean is very important in the processing of raw beans. Whether a coffee bean is good or not, the planting environment accounts for 1/3, the treatment method accounts for 1/3, and roasting accounts for 1/3, so the treatment of a coffee bean is very important to it.

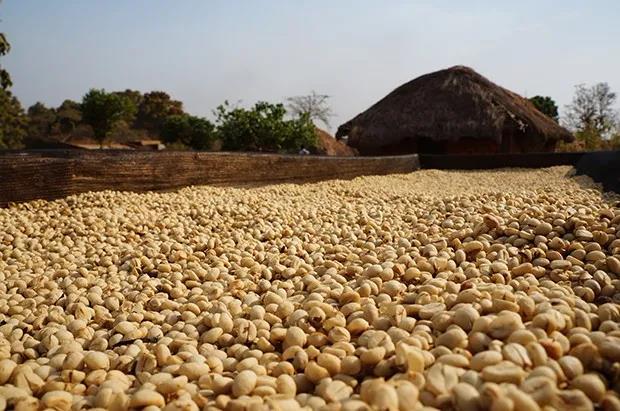

Sun treatment is an ancient method of raw bean treatment, which is generally common in dry, warm and sunny areas. Now, the fruit tone that sun treatment brings to coffee also makes coffee growers around the world take risks to do sun treatment.

The first step is to collect and screen water washing treatment.

After picking the coffee fruit will be hand-selected first to select the defective coffee fruit, including overripe, immature, moth-eaten and, of course, foreign bodies in addition to the fruit.

Step 2; drying

After screening, the coffee fruit will be sent to a drying place for drying, and different regions may use different drying racks, some with tarpaulins, some with high beds, some with cement floors, etc., and the average drying time is 3 to 4 weeks. the drying process was not completed until the moisture content of the coffee was reduced to 11%.

Step 3: peeling

After drying, the coffee fruit is sent to the processing plant for peeling and shelling, and even polished. Peel, pulp and other parts will be removed in this step.

Step 4: sorting, warehousing

Peeled raw coffee beans will be screened again to remove coffee beans that do not look good. This reflects the quality of the coffee drying process, over-dried coffee beans will be more fragile, peeling process will be broken into debris; while under-dried coffee beans have too much water content, water is too active, easy to breed bacteria, mildew and so on.

After screening, it will be sent to the warehouse for storage until it is exported.

The origin of washing treatment is that all treatments are inseparable from sun drying. Coffee fruit contains a lot of sugar, if exposed to high temperature for a long time, the sugar inside is easy to ferment, so that coffee beans produce pungent fermentation acid. At the same time, the sun treatment needs to watch the day to eat, in case of wet season or continuous rain, coffee fruit does not have time to dry / dry uneven, it will begin to rot, coffee beans produce rotten taste. To solve this problem, people began to try to remove the pectin from the peel and pulp first through the water source to reduce the water content of the coffee fruit before drying, so the sun drying time will be greatly shortened, so there is a washing method.

The first step: cleaning / collection / flotation / bleaching

The coffee fruit is actually sent to the processing plant to be weighed within 6-12 hours after picking, and then soaked and cleaned in order to pick out the "little villains" who float on the surface due to insufficient density and clean up the sand and gravel of the branches.

Step 2: peel and flesh off the fruit

Use a machine to remove the skin and pulp, leaving only coffee beans wrapped in parchment. At this time, there is also a layer of mucous membrane on the outside of the beans, so it is necessary to produce acidity through fermentation to make the mucous membrane fall off.

The third step: fermentation-degumming

This mucous membrane is the pectin part. The mucus in the pectin part has strong adhesion and is not easy to remove, so it needs to be placed in a clean sink for about 18-36 hours to allow pectin fermentation to produce acidic decomposition mucus.

Step 4: wash the pectin

After the mucus decomposes, a small amount of water is injected and stirred, causing the pectin decomposition of coffee beans to fall off. After cleaning, you will get coffee beans wrapped in parchment and hard skin.

Step 5: sun drying

After cleaning, defective coffee beans will be selected and then laid on the cement floor / tarp / drying bed for sun exposure. The drying time depends on the weather, and the general drying time varies from 5 to 14 days. The water content of dried coffee beans will be reduced from 55% to 11%.

Step 6; store

After drying, the coffee beans are stored with parchment, which is removed before the coffee beans are exported.

In the traditional treatment of sun-treated coffee, it has the lowest acidity, the highest sweetness, the clearest touch, but slightly lower cleanliness. The flavor is exposed to the sun. Due to the rough conditions and rough treatment, the quality of the old sun-cured coffee is uneven and the defect rate is high. At the same time, the cause of the defect also comes from the strong dependence on the weather. A month of drying requires a continuous and stable high temperature and dry weather. If it rains during the drying period, it will cause mildew of the coffee fruit. However, with the popularity of the sun trend in recent years, many producing areas continue to optimize the details of the sun treatment steps in order to improve the taste of the sun coffee cup. Before drying, flotation will be carried out to remove coffee fruits with insufficient density, and drying sites are also strictly controlled, such as the construction of high beds in Africa, cement drying platforms, and so on, and in order to dry evenly in the process of sun drying, many treatment plants or estates will employ workers to turn them regularly to evenly dry while avoiding excessive fermentation and reducing defects.

Compared with the sun treatment, the acidity and cleanliness of the washed coffee is higher, but the complexity is not as good as that of the sun, while the sun-washed coffee has a heavier berry flavor, complex and sweeter than the washed coffee. Will produce more berry tonality, but also more complex. But the disadvantage is also very obvious, the most primitive and traditional sun treatment method will put the coffee fruit on the drying terrace or directly on the side of the road to direct exposure, due to rough conditions and rough treatment methods, the quality of the old sun-cured coffee is uneven and the defect rate is high. At the same time, the cause of the defect also comes from the strong dependence on the weather. A month of drying requires a continuous and stable high temperature and dry weather. If it rains during the drying period, it will cause mildew of the coffee fruit.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Basic knowledge of barista basic knowledge of hand-brewing coffee brewing skills coffee bean grindability water temperature ratio parameters

[dissolution] and [diffusion] are the principles of hand-brewed coffee, so what does dissolution and diffusion mean? [dissolution] refers to the chemical reaction of coffee beans after roasting to produce coffee ingredients that give off the aroma and flavor of coffee, in which there are a variety of chemical macromolecules and small chemical molecules.

- Next

What kind of tea is Sawduo? how much is a jin of tea? Which is more expensive and tastes better than the fragrant duck shit?

Origin: Hucuo Village, Fenghuang Town, Chaozhou City, Guangdong Province, China season: spring tea harvest date: may 8, 2021 dried leaves: strips compact and neat, dark brown glossy. Bouquet: roasted aromas with hints of flowers and fruit. Tea color: bright orange-red taste: mellow and smooth liquid, with strong aroma, long-lasting and tender aftertaste. Tea varieties:

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?