Espresso Machine Cleaning Backflush Steps Process Semi-automatic espresso machine maintenance tutorial

If the machine is not maintained, it is easy to break down. It's the same with the coffee machine, if one day you find that the coffee doesn't taste right, or if you find that something is wrong with the extraction, there may be a big problem with the coffee machine.

Therefore, we usually have to do a good job of cleaning to avoid these problems. This is divided into two parts: daily cleaning and regular cleaning, aiming at the Italian semi-automatic coffee machine with independent head (full-automatic coffee machine is not applicable).

The first point: keeping the outside of the coffee machine clean and tidy is the most basic requirement, and no one wants to see a dirty coffee machine. Coffee stains should be cleaned up after extraction of espresso. The second point: the more important point is to wash the coffee residue on the water distribution network. After the coffee is extracted, a small amount of coffee grounds on the surface of pressed powder will be attached to the watershed. If it is not cleaned, it will affect the flavor of the next cup. Therefore, after the extraction of coffee, pull out the handle, and then open the cooking head, flush the residue on the powder water net, if the outer ring part of the cooking head and rubber ring, the water can not be washed directly, then it needs to be cleaned with a brush.

The third point: the cleaning of coffee handle, especially the shunt handle. Coffee powder bowls should be washed clean after each extraction, and some will choose to ignore this step when there is a large amount of cups. Qianjie thinks that this is not advisable. Of course, most coffee shops still follow this principle. At the end of the day, be sure to pry open the powder bowl and clean the inside of the handle when using the shunt handle. After a day of extraction, the shunt pipe in the handle will leave a lot of coffee residue and grease, if it is not cleaned, it will give off a bad smell, which will naturally affect the quality of the coffee behind. (Qianjie has seen that the inside of the handle is not washed for a week, which is unforgettable for the rest of his life.)

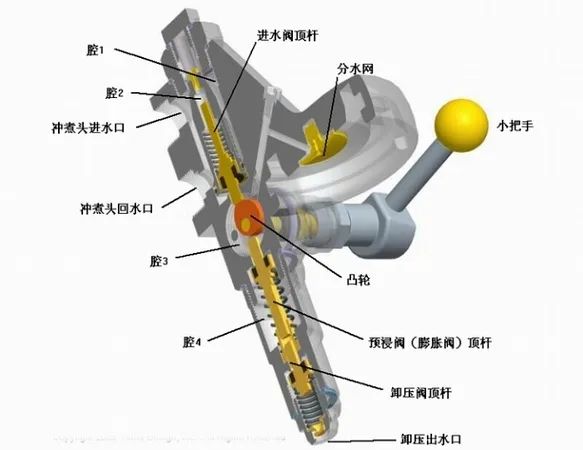

This picture shows the situation after one extraction, because Qianjie mainly uses bottomless handles, so it is difficult to imitate the dirt map accumulated over the years. Therefore, Qianjie suggests soaking in hot water 5g coffee machine cleaning powder for 30 minutes, and then rinsing it with clean water. This effect will be more significant. The fourth point: backwash and clean the inside of the coffee machine. This involves the structure of cooking. Here in front of the street, a structure diagram of E61 cooking head is released for your reference.

"when making coffee, move the handle up to the horizontal position, the microswitch behind the handle is pressed, and the pump starts. At this point, the prepreg valve and the pressure relief valve are closed, while the intake valve is open. When hot water is injected into the open pipes and cavities of the cooking head, the pressure rises. When the pressure exceeds 1.5 atmosphere, the prepreg valve (expansion valve) opens and hot water enters cavity 4. As a result, before the hot water is filled with 4, the coffee cake is pre-soaked at 1.5 atmospheric pressure. Once cavity 4 is filled, the hot water pressure begins to rise again until the required 8-10 atmospheric pressure is required. After the coffee production is completed, the handlers are moved to the vertical position, the fretting switch is closed, the water pump is stopped, and the cam releases the intake valve ejector rod and the pressure relief valve ejector rod, and the pressure relief valve is opened. the pressurized hot water in the cavity between the brewing filter bowl and the water distribution network, cavity 3 and cavity 4 is discharged from the pressure relief outlet to the coffee machine drain tank. "in this extraction process, a small amount of fine coffee powder will enter the pipeline through the water distribution network, and if it is not cleaned for a long time, it will accumulate a lot of coffee residual powder, affecting the extraction. Therefore, in order to clean the inside of the cooking head, we will use a "blind bowl", that is, a powder bowl without fine holes. Buckle on the handle, then buckle on the cooking head to open the cooking. The time is recommended to be controlled within 10 seconds, repeat several times, each time to pour clean the water in the blind bowl, usually the first one or two, coffee residue will fall out.

Another item is to clean the interior of the coffee machine with cleaning powder. This is not used every day. If it is used frequently, once a week is recommended. If it is used at home, 2-3 cups of extract per day is recommended once a month. Put 3G coffee machine cleaning powder in the blind bowl, then buckle the handle to open the first 10 seconds, then pull out the handle, pour out the surface water (normally there is still cleaning powder left in the blind bowl), buckle the handle again and wash repeatedly for 3 times.

Then pull out the handle, clean the blind bowl, open the brewing head at the same time, and release the water (the water is mixed with cleaning powder foam and coffee residue). After the water is a little cleaner, continue to buckle the handle and open the brewing head for 5 seconds. Repeat this step 5 times, each time to pour the water out of the blind bowl. Finally, clean the water diversion net with a brush.

Fifth point: regular cleaning of the water distribution network, replacement of rubber rings and boiler maintenance. If the water from the head is uneven, it may be that there is coffee powder left on the water distribution network, then it is necessary to open the powder water network to clean it, which usually occurs in about half a year. The function of the rubber ring is to seal the coffee handle. For a long time, the rubber ring will harden and the sealing effect will become worse. The most obvious feature is that the handle angle is more than 90 degrees when the coffee handle is fastened. At this point, it needs to be replaced. The life of aprons is usually 6-12 months. Long-term use of the boiler will leave a lot of scale (unless pure water is used), which needs to be handed over to a professional to clean up. If it is a new machine, it will be maintained about 1-2 years.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

What is the shelf life of freshly roasted coffee beans? How long is the best cultivation period for hand-brewed coffee beans?

In the past, when we bought food, we would pay attention to the production date, and then look at the expiration date, because it is common sense that we should try not to eat food after the expiration date. But on the coffee beans, the production date refers to the baking date, that is, the time node when the coffee beans are cooked. But we keep an eye on this baking date.

- Next

Hand-brewed coffee beans appear green and bitter taste solutions what coffee beans are not astringent recommended

Whether the coffee is mellow or not may be imperceptible for a while, but the unpleasant feeling of coffee, such as the rough astringency of sand, is clearly noticeable. Therefore, we need to recognize and avoid the occurrence of such things. Qianjie has also been popular in previous articles. Astringency is not a taste, but a taste.

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?