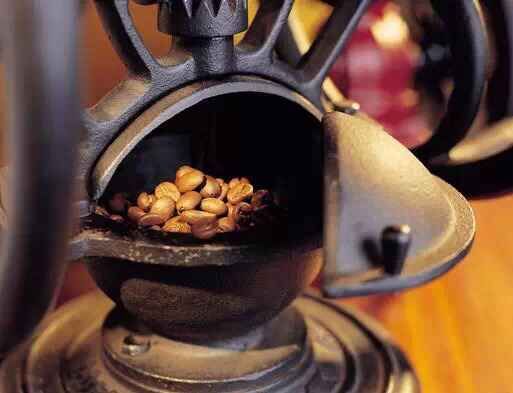

The small details that should be paid attention to in roasting coffee beans determine the success or failure of the roasting effect.

Baking this heat treatment causes significant chemical and physical changes in the structure and composition of raw coffee, causing the beans to darken and emit the unique aroma of roasted coffee.

1. The purpose of coffee roasting

The main purposes of coffee roasting are: 1, aroma; 2, increase the complexity of coffee; 3, to obtain color; 4, to form the unique flavor of coffee and so on.

2. The way coffee is roasted

According to the baking time, it can be divided into two types: fast baking and slow baking. According to the baking machine, it is divided into two types: family workshop type and industrial type.

3. The roasting process of coffee

The first stage of baking is heat absorption, in which raw coffee beans are slowly dried until they turn yellowish, when the baking smells like baked toast or popcorn.

The second stage, commonly known as the first explosion, usually occurs around 205℃, during which the coffee beans double in size, change to a light brown color and lose about 5 per cent of their weight.

The third stage is from the first explosion to the second explosion, the temperature rises from 205℃ to 220℃, the color changes from light brown to moderate brown, and the weight loss is about 13%. This chemical process, called pyrolysis, converts the chemical composition of coffee beans and releases carbon dioxide. The third stage is the second endothermic period, followed by the second exothermic period, called the second explosion, the second pyrolysis takes place at about 225230 ℃, baking about medium-deep brown, the sound of the second explosion sounds dense and fast, and the surface of the coffee bean is covered with a layer of oil.

In the process of segmented heating in a bean dryer (usually using a large, hot rotating cylinder), the remaining water in the coffee bean cells turns into steam, prompting the rich carbohydrates, proteins, lipids and minerals to undergo a variety of complex chemical reactions. Coffee beans begin the caramelization process at 170200 ℃. At 185240 ℃, carbohydrates combine with amino acids, peptides and proteins for caramelization, which is known as the "Mena reaction". Caramelization is one of the most important factors affecting the flavor of coffee. After baking for 6-7 minutes, raw beans absorb a lot of heat and start the pyrolysis reaction. Pyrolysis can last until the second explosion, although caramelization is an important process to awaken the aroma of coffee, but with the extension of baking time, some ingredients will also be carbonized to form a bad astringent bitter substance, how to get the highest caramelization. At the same time, carbonization should be reduced to the lowest point, which is the highest technical link of roasting coffee beans. During the roasting process, the volume of coffee beans increases by at least half, while the weight of beans decreases by 1. 5%.

Source: network

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Four classic Espresso introductions and drinking methods

The person who translated Espresso into Kung Fu Coffee must have worked hard and knew that Espresso was second to none in the coffee world. Like Kungfu Tea, in addition to the nature of tea, there is also a sense of fighting, high-end fighting equipment, sophisticated fighting techniques, but also the ability to distinguish guests. Espresso is the soul of coffee. People call it espresso, as its name implies.

- Next

The effect of bean grinder on the flavor of coffee-it is important to choose the right bean grinder

Like drinking coffee, is a hobby, like making coffee, is a kind of mood, like making coffee, is a way of life. In China, more and more people begin to fall in love with coffee and coffee life. Baristas constantly study how to make better coffee. Constantly try different flavors of coffee beans, different tastes brought by various brewing utensils, and all kinds of brewers.

Related

- What is the meaning of lactic acid fermentation with coffee bean treatment?

- How to judge the state of foam by sound?

- How does the latte pull out the unicorn pattern? Come to get for a little trick to improve the flower pull!

- Will flower pulling affect the taste of the latte?

- Do you know the history of coffee?

- The difference between honey treatment and sun washing what is raisin honey treatment?

- What kind of milk can a novice use to make coffee foam to keep the foam longer? The correct method and skills of milking tutorial sharing

- Why do washed coffee beans taste sour? Flavor characteristics of washed Coffee

- Introduction to the skill of how to practice the size and height of water injection around the circle of hand-brewed coffee

- How do beginners practice coffee flower drawing from scratch?