The basic structure of coffee roaster the structure, manufacture and operation technology of coffee roaster are analyzed in detail.

On the surface, the coffee roaster seems to be very complicated, but in fact, the structure is relatively simple. The roaster is composed of raw bean holder, drum, dust collector, dust collector, cooling tank and so on. The whole baking process of raw beans turning into ripe beans is mainly controlled by control panel, adjusting turntable, sampling spoon, baking / cooling switch and so on. Of course, good or bad roasting requires some experience and skills. This only belongs to the category of human level experience. Here we only focus on the main parts of the coffee roaster to explore its function.

Air valve:

The main functions of the gas valve are as follows: the exhaust function of waste such as smoke and broken layers, providing the necessary oxygen during bean combustion, and adjusting the heat in the drum. Basically, the air valve mainly has the function of "the temperature of the drum rises when it is opened and decreases when it is closed". After putting the raw beans, immediately enter the "steaming mode" (need to close the gas valve) to homogenize the beans, which is also one of the important functions of the gas valve.

The air valve has exhaust and cooling sharing type, and the two separate types. The shared type requires a "baking / cooling switch" to control the baking of raw beans and the cooling of cooked beans out of the tube.

Roller:

The drum structure of direct fire type and semi-hot air type is very different, but the basic condition is that the stirring blade which can bake beans evenly is also suitable for rotating speed. If you put as many raw beans as the capacity of the roaster, it will cause uneven baking and difficult exhaust. Most of the causes come from the structure of stirring blades. The roaster pushes the beans to the front of the drum according to the centrifugal force generated during rotation, so that the beans are fixed in a ball. In general, it is best to bake up to 80% of the beans.

Smoke exhaust equipment:

Raw beans in baking produce quite a lot of dust, broken layers, and silver skins, and dust collectors are the machines that collect these things. There is a horizontal pipe connection between it and the roaster, and then to the chimney outside the house. The curved part of the chimney will cause turbulence, so it is installed in a straight line as far as possible, so that the chimney extends to a considerable height. The chimney is not just a simple exhaust outlet, it is also its job to extract the air accumulated in the dust collector.

Cooling device:

If the beans are not cooled immediately after baking, the beans will continue to bake with their own waste heat, which will make the taste more bitter.

Firepower device:

The temperature of the roaster is controlled according to the firepower of the burner and the multiple adjustment of the gas valve. The firepower setting end depends on the gas pressure gauge, and the micro-adjustment depends on the gas valve.

A Collection of Coffee Taste

Source:

VisibleCafe's blog

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

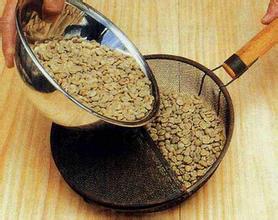

A brief introduction to the technical skills of using hand net to bake coffee beans at home

Hand net is also called manual roaster. The biggest advantage of hand net baking is that it can remove smoke, avoid the smoky taste of coffee, and make it easier to observe the changes in the appearance of beans during baking. When baking coffee beans with a hand net, the firepower is fixed in a strong medium fire. After fixing the firepower intensity, the distance between the hand net and the flame is adjusted according to the firepower intensity. The position of the hand net and the tile

- Next

Prevent the extraction of coffee tannins if you make a good coffee correctly to prevent the astringency in the coffee.

Coffee contains a variety of ingredients, extraction is not to extract all of them. There is usually this rule: if the amount of coffee powder is constant, the amount of extraction of soluble components is determined by the degree of grinding and time. The finer the grinding degree of coffee powder is, the longer the extraction time is, the more ingredients will be obtained. According to the experiment, if all the ingredients that can be extracted from the quantitative coffee powder are extracted.

Related

- What is the meaning of lactic acid fermentation with coffee bean treatment?

- How to judge the state of foam by sound?

- How does the latte pull out the unicorn pattern? Come to get for a little trick to improve the flower pull!

- Will flower pulling affect the taste of the latte?

- Do you know the history of coffee?

- The difference between honey treatment and sun washing what is raisin honey treatment?

- What kind of milk can a novice use to make coffee foam to keep the foam longer? The correct method and skills of milking tutorial sharing

- Why do washed coffee beans taste sour? Flavor characteristics of washed Coffee

- Introduction to the skill of how to practice the size and height of water injection around the circle of hand-brewed coffee

- How do beginners practice coffee flower drawing from scratch?