Structure understanding of Coffee Roaster

Pay attention to coffee reviews (Weixin Official Accounts vdailycom ) and find a beautiful cafe to open your own shop

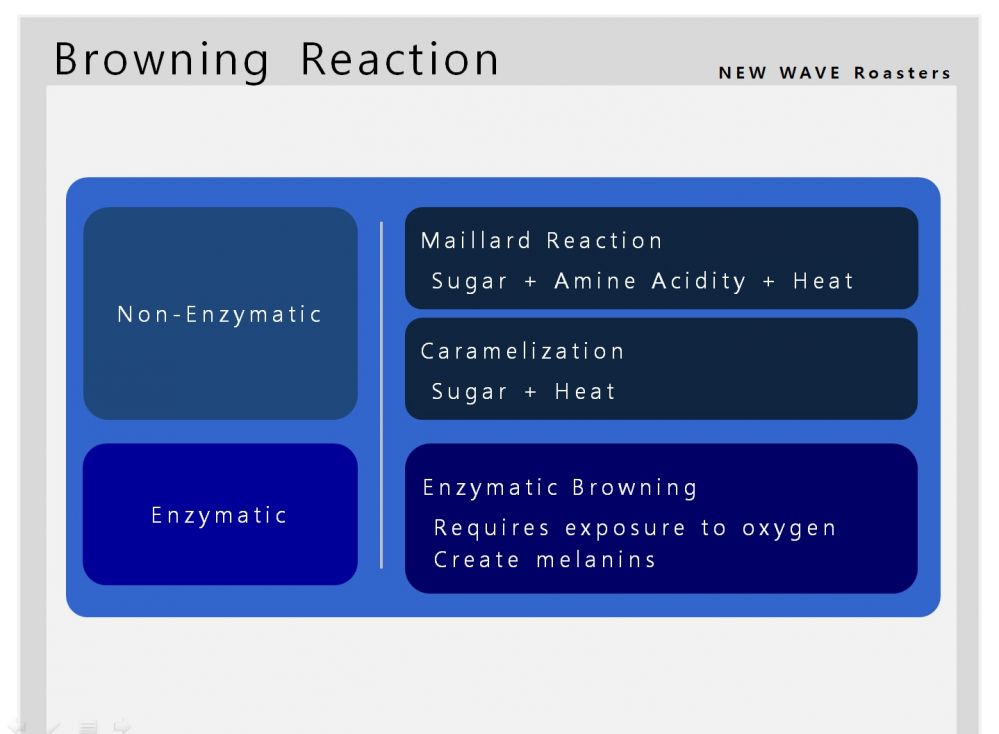

If coffee roasters understand the structure of their roaster, they can effectively control the entire roasting process. The coffee roasting process is a process of changing the flavor of green beans into mature beans through thermal Non-Enzymatic Browning.

Heat is a physical property quantity, measurable and proportional to temperature. The heat of roasting plays a leading role in coffee flavor change, so it can be said that antipyretic is equivalent to understanding roasting. No overheating is difficult to quantify, and it is impossible to bake with exactly the same amount of heat every time. Therefore, it is important for bakers to understand the types, functions, and differences of heat in order to maintain complementary relationships.

Types and Understanding of Heat

The heat used in baking can be divided into convection, conduction and radiation. Each roaster uses a different ratio. General drum roaster (Solid Drum), then through the combustion furnace heating drum, drum inside the beans by convection and conduction heat.

For example, Probat's Type-1 uses Conduction 2: Convection 8, but the new Type-2 uses almost 100% Convection.

Giesen's W6 model uses conduction 4: convection 6, while the W15 model uses conduction 1: convection 9.

Probat on the left and Giesen on the right.

Conduction is the transfer of heat from a higher temperature part of an object to a lower temperature part of the object, and the heat transfer rate to the green beans is slower. After baking, the proportion of conduction is very large in the process of heat absorption of green beans. However, overheating of the drum can lead to scorching.

Convection is the process of heat transfer through macroscopic flow of gas or liquid through its various parts. Convection is more efficient and uniform than conduction. The proportion of heat transfer to green beans is the most in the whole baking process. However, poor exhaust balance can lead to baking times that are too fast or too slow.

Radiation is emitted outward in the form of electromagnetic waves and particles, and heat can be transferred without a medium. Heat transfer to the outside and inside of the green beans is uniform, but it is difficult to control, and the actual roasting accounts for a small proportion.

▲ Types of heat

Types and characteristics of burner (Lamp)

The combustion furnace of the baking machine can be divided into two, the Environment-Lamp and the Infrared-Lamp.

The flame of an ambient furnace (or gas furnace) is blue and low in height. It is used in most commercial baking machines. The taste is characterized by good acidity and body.

The flame of the infrared furnace is red and has no height. A typical roaster using this oven is the American Diedrich. The taste is characterized by a balance of sourness and sweetness.

Left-infrared stove, right-gas stove

Drum and heating method

The structure of the drum baking machine (Solid Drum) is that there is a combustion furnace under the general drum. Therefore, if the single drum is used, it is easy to cause scorching phenomenon. Some roasters avoid this problem by installing a heat sink between the burner and the drum, but this does not control the heat from the heat sink and it is not easy for the baker to control the roaster.

Double Drum is made of two steel plates, some of which are made of different materials for the outer and inner plates. Because of the double layer, the heat conduction is low and the probability of burning is low. Therefore, the double roller baking results are more uniform and stable than the single roller baking.

Left-double roller, right-single roller

The baking machine with 100% convection mode (hot air type) will not directly heat the drum, so it will hardly burn. The baking curve of this baking machine is HTST(High Temperature Short Time), baking time period, high production efficiency. A typical roaster that uses this approach is the Loring in the United States. The taste is characterized by high acidity and low Body.

It can be seen that the heat transfer ratio and mode of each roaster are different, and coffee roasters should understand the structure and characteristics of their roasters to apply them. The more detail the roaster knows, the more complete the coffee will be.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Top6 recipe of 2017 World Coffee Brewing Competition

At the World Coffee Brewing Competition held in Budapest, Hungary last month, our BlackWaterIssue's official website introduced the contents of the champion Wang ce and the fourth Michael manhart. Today we will introduce to readers the contents of the other four finalists and their extraction recipes. Sam Corra (Ona Coffee) / Australian specified brewing (

- Next

The brewing formula of Dylan Siemens, the champion of 2017 American coffee brewing contest.

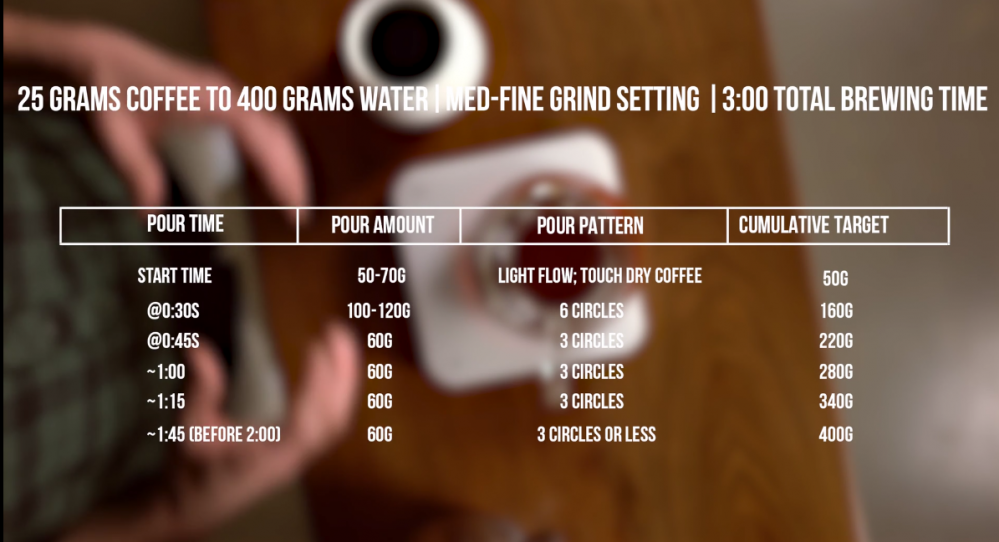

Dylan Siemens, winner of the 2017 American Coffee Brewing Competition, unveiled Kalita Wave's brewing recipe on Onyx Coffee Lab's official website. Dylan's formula is different from the existing one, and he will introduce his Pouring in more detail. ■ Kalita Wave Formula Coffee Powder: 25g Water: 400g Grinding scale: medium Fine Water temperature: 90-96 degrees in pre-soaking stage

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?