Professional coffee roasting | experience of air temperature measurement

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

Personally, I think that no matter how high-end the roaster is, if you really want to grasp its characteristics, you must have at least four measurement data to compare, otherwise you can only spend a lot of time and beans constantly trial and error. The four measurements are

Intake air temperature (Inlet air temperature): the temperature before the outside air enters the combustion chamber after heating by the fire row, and the semi-hot fan usually measures the ambient temperature outside the air intake hole at the bottom of the baking bucket; the direct fire machine has more air intake points because of more holes, or it can be represented by the ambient temperature above the baking bucket; the hot fan can measure the air temperature at that point before the hot air enters the baking chamber.

Furnace temperature (ambient temperature, Environment temperature/Drum temperature/ Ambient temperature): the probe is usually installed with a hole in the front plate of the roaster, where the probe does not come into contact with the bean pile, and the temperature of the air in the baking bucket is measured.

Bean temperature (Bean temperature): usually install a probe with a hole in the front panel or the lower bean baffle of the baking machine, which is located just so that the probe is buried in the bean pile, ensuring that most of the measured temperature is the bean temperature.

Exhaust air temperature (Exhausted temperature): the position of the probe is located on the exhaust air path, which may be in the exhaust port of the baking bucket, the middle of the trigeminal tube of the bean exhaust, the back end of the exhaust pipe of the baking machine, etc., depending on the design of each manufacturer, the influence of the setting position and the measured value is very great. The farther the setting position is from the exhaust outlet of the baking bucket, the greater the difference in value will be. Since the exhaust temperature is the measured number after the baking bucket and the inhaled air are heat exchanged with the beans in the bucket, it is very important for the control of the baking process. At the Home-barista Forum, a proper term MET (maximum ambient temperature of Maximum Environment temperature) is selected for the number measured at the exhaust port of the baking bucket, which is separated from the ET (furnace temperature Environment temperature, exhaust air temperature Exhausted temperature) set at other locations. MET is a very important measure for me, especially when thinking about the hot air ratio of bean baking, so my current exhaust temperature is MET.

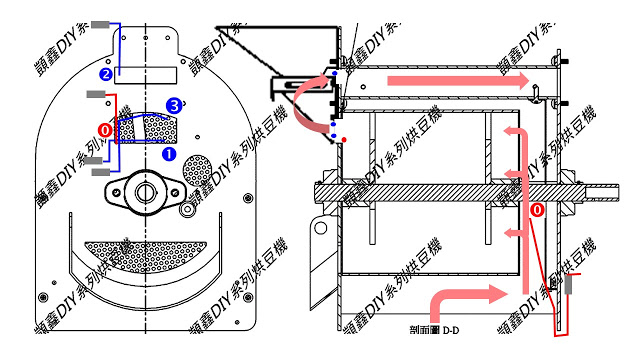

For the measurement of bean temperature and furnace temperature, the general bean dryer should be equipped, so I don't need to spend much time on explaining. What I want to share is my DIY002, which measures the inlet air temperature and exhaust air temperature, because these two measurement points are installed by myself, using a non-destructive plug-in mode, and the inlet air temperature is a foldable stainless steel probe with a diameter 1.5mm and long 20CM. The installation location indicates the red broken line (the measuring point is red (0)) on the right, the exhaust air temperature is a foldable stainless steel probe with a diameter 1.0mm and long 5CM, and the installation position is shown on the left of the figure below. The red broken line (0) is currently used, and the remaining blue broken line (1) (2) (3) is the previously installed position.

My inlet exhaust air temperature measurement point, the red (0) position is the currently used measurement point, and the blue (1) (2) (3) is the exhaust air temperature measurement point that has been set.

The front on the left and the side on the right (front on the left and back on the right)

(the original picture is the design of Dong Tsai, thanks to Dong Tsai.)

First talk about the wind temperature, my DIY002 because the back plate has two layers of thermal insulation cotton, it is not good to enter the probe by the ready-made hole position, the way I use is from the bottom of the backplane (not the bottom of the base, because the base can rise and fall) U-shaped circuitous entry, and then use the screws on the backplane to try to fix (be sure to be fixed, listen to someone in the industry to add air temperature probe, the result was twisted into the baking bucket, it must be a disaster). Because the inlet air temperature measures the ambient temperature outside the air intake hole at the bottom of the baking bucket, when the exhaust air volume is fixed, it can be found that its value and firepower are very sensitive, the fire temperature increases, and the fire temperature decreases immediately, when the firepower is fixed, the connection with the exhaust air volume is also very clear (but there is a critical value), the inlet air temperature decreases rapidly when the exhaust air volume is greater than the critical value, and the inlet air temperature rises rapidly when the exhaust air volume is less than the critical value. Therefore, it is conceivable that if you want to operate baking with a high hot air ratio, you should determine the amount of exhaust air according to the amount of beans, and then control the firepower after a fixed amount of exhaust air, which will be relatively easy to operate, and this philosophy is also the basic design concept of large factories such as Probat. If the firepower is also adjusted, the ventilation is also adjusted, and only the bean temperature and furnace temperature can be used for reference, because there are too many variables, too little information, and too much knowledge in the middle, I can't learn.

If you look at the exhaust air temperature, there is little difference between the settings of (0) and (1) above, and (1) is also the setting I have used for the longest time, but because it is horizontal below the mouth of the bean, it often gets stuck with one or two beans. I changed it to (2) to keep it away from the mouth of the bean and closer to the entrance of the exhaust pipe. Although the probe is moved from (1) to (2) only a few centimeters away, because there is no thermal insulation in the bean trough, and the hot air is pumped out from the baking bucket to the exhaust outlet, the temperature is greatly affected by the external environment. As a result, the final measured temperature difference (after an explosion) can be as low as more than 40 degrees, which becomes of no reference value, so I moved it to the position of (3). It is the upper edge of the hot air outlet of the baking bucket, and this position is not easy to get stuck. However, the position of (3) may be too located at the outer edge of the exhaust port, and the final measured temperature difference will be as low as more than 20 degrees, which is still not satisfactory. Finally, I found the position of (0), and its measured value is similar to that of (1), but slightly higher. It doesn't matter, because what I want is the first-hand data of the air temperature and the environment in the barrel.

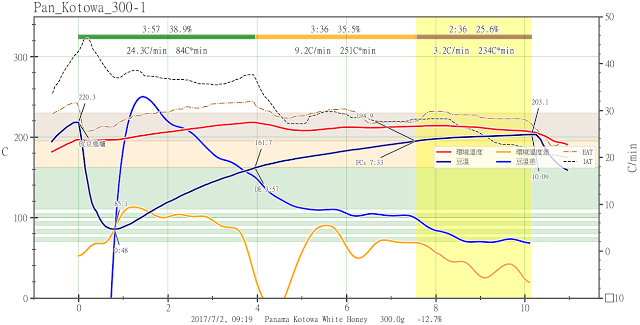

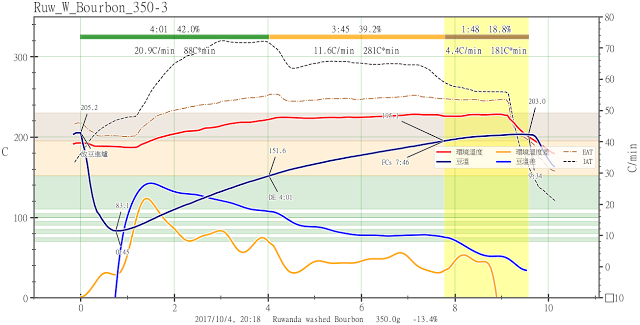

The black dotted line is the inlet air temperature and the brown dotted line is the exhaust air temperature. the measuring point of the exhaust air temperature in this picture is (1). If you look carefully, you can find that the exhaust air temperature curve is consistent with the red furnace temperature curve, and sometimes the inlet air temperature is lower than the exhaust air temperature. this pot obviously has a low hot air ratio and eats more in contact with hot food.

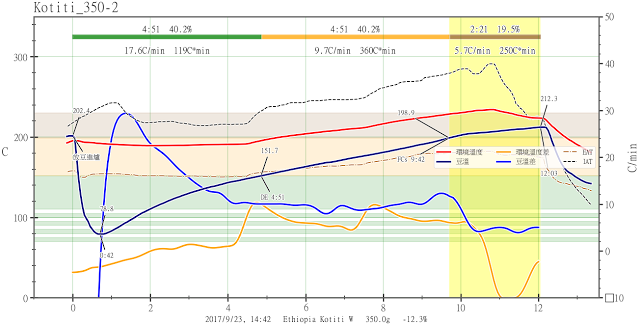

The black dotted line is the inlet air temperature and the brown dotted line is the exhaust air temperature. The measuring point of the exhaust air temperature in this picture is (2). At this time, the overall configuration of DIY002 is the configuration of high hot air ratio. We can find that the trend of the inlet air temperature and exhaust air temperature is the same, but the measuring point of the exhaust air temperature deviates too far, and the measured number is more than 40 degrees, which becomes of no reference value and must be moved again.

The black dotted line is the inlet air temperature, and the brown dotted line is the exhaust air temperature. The measuring point of the exhaust air temperature in this picture is (3) the upper edge of the baking bucket exhaust outlet, at this time, the overall configuration of DIY002 is the configuration of high conduction heat, the baking rhythm is the way of burning in the middle of SSFF, and most of the exhaust air volume is maintained at 50: 60%. Because the barrel temperature is dominant, the comparison of inlet air temperature and exhaust air temperature is meaningless, and the exhaust temperature figure of this measuring point is still slightly lower. Stability also has room for improvement, so move again

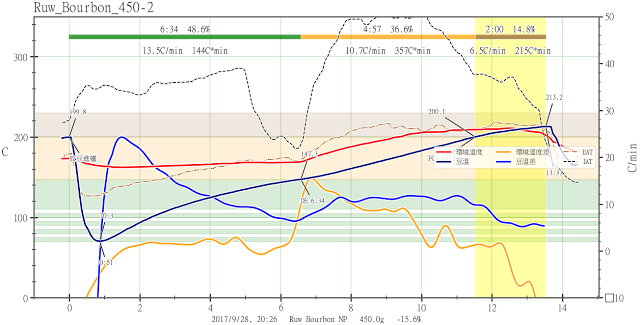

The black dotted line is the inlet air temperature, and the brown dotted line is the exhaust air temperature. The measuring point of the exhaust air temperature in this picture is the final position of (0). At this time, the overall configuration of the DIY002 is the configuration of high hot air ratio. Before the explosion, except for a short time before turning yellow, the ventilation is maintained at 60%, and the firepower is gradually reduced from 80% to > 50%. After the explosion, the air volume is increased to 80% and then the fire is reduced, and the flick point is flameout and glides to the lower bean. The RoR of bean dip is about 2.5. Whether it is the exhaust air temperature or the furnace temperature, the trend is consistent with the inlet air temperature, and the high bottom of the inlet air temperature is mainly determined by firepower.

How to confirm that your machine is configured with high hot air ratio? My method is to see whether the first-hand exhaust air temperature (MET) is more affected by the furnace temperature (ET) or the inlet air temperature. In principle, the MET with high hot air ratio will not be lower than ET. However, this is my view and empirical process, savages expose errors are inevitable, please do not believe.

With the measurement of inlet air temperature and exhaust air temperature, we can confirm whether the baking method adopted is mainly hot air or conduction heat, so as to create the flavor we want, while the exhaust air temperature (MET) can guide us to control the fire (whether it is a high hot air ratio or not), such as controlling MET between 210 and 240 after yellowing (a range inferred by myself from other literature) to avoid too strong or too weak firepower. Can develop a good flavor.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

New concept of coffee-who should drink less coffee

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style) [the harm of coffee to your health] 1. At present, there is no direct evidence that caffeine can lead to osteoporosis, and some studies have found that although caffeine increases calcium excretion, it is not a high risk factor for osteoporosis. Insufficient calcium intake is the main cause, so it is still recommended that

- Next

Professional coffee roasting | how to bake without temperature timing? Rely on the nose.

Communication of professional baristas Please pay attention to the coffee workshop (Wechat official account cafe_style) without a thermometer, I will only make a mess, but Willem Boot has set a few milestones for the bean baking process, which I think is quite valuable, although it is a bit brief. If you think the baked bean theory is too complicated, you can add or subtract it. The original text is here (but there is a big marking error in the article).

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?