Professional coffee roasting | adjust the air only, not the fire, or just the heat?

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

The discussion of Home-barista is worth taking a look at [Air flow in roasting]. It starts with Scott Rao's correct airflow, how Giesen judges airflow is at the right level, and then induces Rich to talk about more airflow means low RoR from a professional point of view. (the more flirtatious, the lower the RoR.), it also mentions that Diedrich and Boot publicly

A typical airflow profile for a roast master using an IR roaster such as a Diedrich, is 25% for Drying, 50% for Ramp, and 75% for D evelopment.

The typical air flow ratio of infrared roaster is dehydration 25%, Mena 50%, development 75%.

However, Rich believes that the use of greater romance in the development stage is disadvantageous to the control of RoR, while

The point is there's no "right" airflow for a classic, drum roaster-it's circumstance and roast master dependent.

There is no such thing as the right romance in the traditional drum roaster, which is highly related to the environment and the baker.

Therefore, Sing Yeh said a long time ago that there is no God of Food at all, or everyone can be a God of Food.

The role of hot air in coffee roasting is more and more recognized, whether the roaster is direct, semi-direct, semi-hot air, or hot air, or even a steel gun without a throttle, through the stirring of the blades in the bucket, hot air can play an important role in heat transfer and uniform baking. It's just, what is the right affair? Even if it is a famous door machine with a fixed throttle door, the design of its ABR (air to bean) must be determined according to a certain baking quantity (for example, 1/3 of the baking bucket). If the baking quantity is different, its ABR is different, and the rest of the bean roaster should be the same.

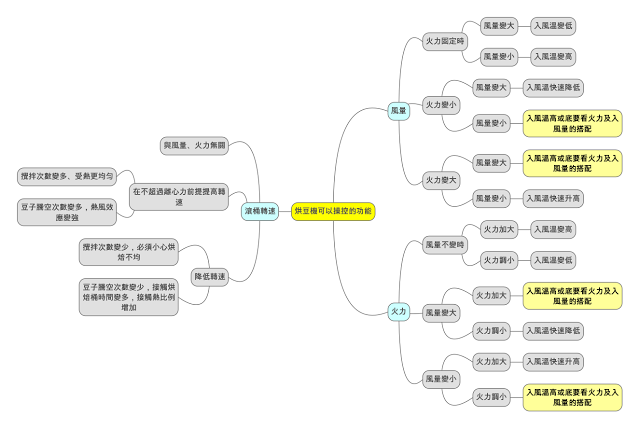

Returning to the fundamentals, the weapons that the roaster can use are firepower, air volume, barrel speed, and, of course, other weapons, such as bean intake, bean temperature, etc., but for the sake of presentation, they are still locked in firepower, air volume and rotational speed. There is only no correlation between the rotational speed and the measurement and comparison of bean temperature, furnace temperature and exhaust air temperature.

When the firepower is fixed: if the air volume increases-> the incoming air temperature becomes lower; if the air volume becomes smaller-> the incoming air temperature becomes higher.

When the firepower is adjusted small: if the air volume increases-> the incoming air temperature decreases rapidly; if the air volume decreases-> the incoming air temperature is high or the bottom depends on the combination of firepower and incoming air volume.

When the firepower is increased: if the air volume increases-> the incoming air temperature is high or the bottom depends on the combination of firepower and incoming air volume; if the air volume decreases-> the incoming air temperature rises rapidly

When the air volume is constant: if the firepower increases-> the incoming air temperature becomes higher; if the firepower is reduced-> the incoming air temperature becomes lower.

When the air volume is adjusted: if the firepower is increased-> the incoming air temperature is high or low depends on the combination of firepower and incoming air volume; if the firepower is reduced-> the incoming air temperature decreases rapidly.

When the air volume is adjusted small: if the firepower increases-> the incoming air temperature rises rapidly; if the firepower is adjusted-> the incoming air temperature is high or low depends on the combination of firepower and incoming air volume.

Drum speed has nothing to do with air volume and firepower.

When the rotational speed is increased without exceeding the centrifugal force, the stirring times become more, the heating is more uniform, the soybeans are emptied more times, and the hot air effect becomes stronger.

When the rotational speed is reduced, the number of stirring becomes less, the baking must be carefully uneven, the soybeans are emptied less, the contact time in the baking bucket is increased, and the contact heat ratio is increased.

Let's take a look at Ota Taguchi's point of view.

Tian Lao does not adjust firepower, but only changes exhaust because he is afraid of destroying the balance between firepower and exhaust, which can be verified by the curve data attached to his collection of boutique coffee.

For the same beans, the difference in baking conditions is that the firepower of one pot is 0.9 KPa and that of one pot is 1.1 KPa. The whole firepower is not adjusted, and the exhaust gas is adjusted from 800 RPM into the bean, 1000 RPM in the first burst and 1200 RPM,RoR in the second burst, and the bean temperature curve rises slowly almost in a straight line.

What is the balance between firepower and exhaust? In my way, for the first pot, the gas pressure of 0.9 KPa and exhaust exhaust of 800 RPM can make the air temperature reach a certain high temperature while maintaining stability when preheating is completed. When entering the first explosion, the exhaust air is pulled to 1000 RPM, so that the inlet air temperature drops slightly, and the beans do not heat up too fast when entering the exothermic reaction, and when the second explosion is completed, it is pulled up again to 1200 RPM, in addition to lowering the air temperature. It also allows you to go into deep baking to produce a large amount of smoke that can be quickly removed. However, since Mr. Tian did not include temperature data, it all ended with my own conjecture.

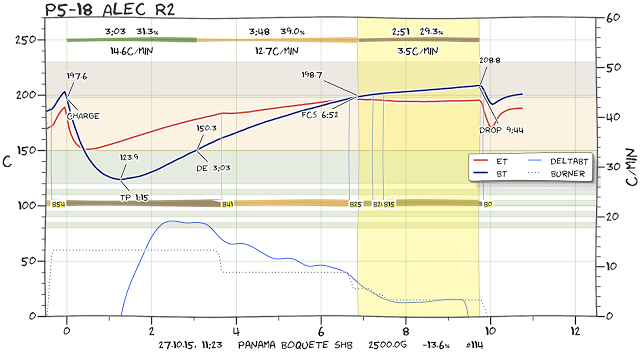

Another example is the curve of a ProbatOne 5Kg bean baking machine with a fixed throttle in the German 2015 SCAE Baking Competition.

The initial firepower of ALEC is 60%. With this firepower and a fixed exhaust air volume, the RoR can reach 18 degrees per minute. After the dehydration stage is completed, the firepower is reduced to 40% and the ROR is also significantly reduced. Before the explosion, the firepower is reduced to 30%. At this time, the bean temperature begins to exceed the exhaust temperature (ET), indicating that under the combination of 30% firepower and a fixed exhaust air volume, the inlet air temperature is lower than the furnace temperature, and the heat energy is transferred. It has changed from hot air to the conduction of baking buckets and the radiant heat of beans into exothermic reactions. the function of ventilation is to remove smoke and dust, and to slow down the heating rate of beans during the development period. In the end, the firepower dropped to only 20%, and the bean temperature was further apart from the discharge temperature. This is the champion curve that bakers make good use of ProbatOne, which uses thick cast iron pans and emphasizes that hot air accounts for 70% of the machine's efficiency. Similarly, because there is no temperature data, everything is just my guess.

Do you remember the tips for baking Taiwan beans 75Compare 85 released by James? Without ventilation, the firepower is reduced by 30% (= 50%) at first, 15% (= 35%) at 180 degrees, 15% (= 20%) at 200 degrees, and then rise from 200 degrees to 214 degrees in a minute and a half, and the firepower is only 20%. Looking at this data alone, I believe that most machines cannot do it, but whether it works in principle, the key point is the design of the pot body, fire platoon, air path, temperature holding capacity of the machine, and finally the imagination of the bean baker's head.

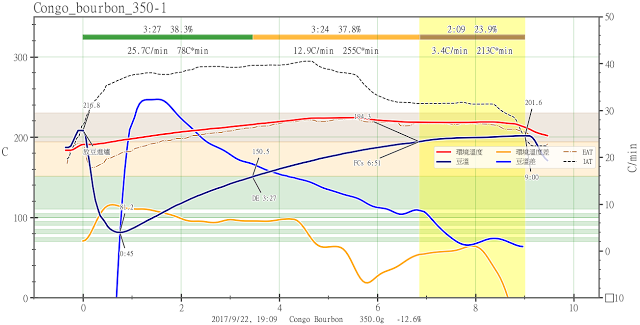

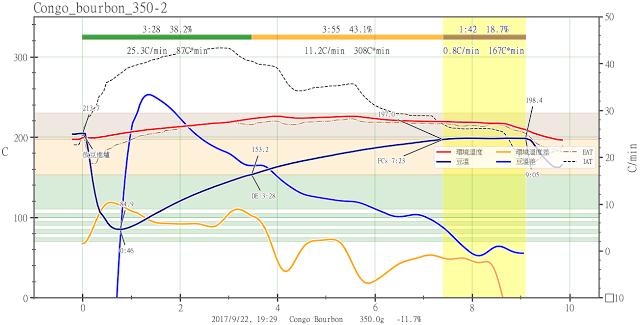

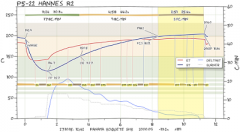

With so many quotes, you have to prove it yourself. Before, I have found the best configuration of this DIY002 with high hot air ratio baking, which is of course due to the addition of temperature and exhaust temperature measurements. This time, a total of three pots were tried and the bourbon was washed with not-so-soft Congo water.

The first pot, the ventilation is fixed, only adjust the firepower.

In the second pot, if you want to have a fixed firepower, the exhaust should be increased by stages from 25%-> 50%-> 80%, but the ROR of the Mena stage is too low and a little ignition is secretly added. Even so, the RoR in the development stage is still too low, so low that stall occurs.

The third pot, the baking method of stably entering the air temperature, the air volume is from medium to large, the firepower is determined by the temperature, the dehydration section is not adjusted, the firepower of the Mena section is slightly increased with the wind volume, and the fire is reduced in the latter half of the development stage.

Cup test immediately after baking, the first pot is slightly astringent, the second pot is lack of acid, and the third pot has the best sense of balance. The next day, the first pot has no astringency under normal high temperature conditions, the second pot has slightly higher acidity, and the third pot is balanced and delicious.

If there is little difference in the flavor of the baked product, I think the simpler the method is, the more valuable it is, the less the cause is, and it is easier to find it when something goes wrong. The method is too complicated, it is difficult to prove that it is that factor that makes the whole pot better or worse, and it will be difficult to accumulate baking knowledge and experience.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

New concept of coffee-drinking 3 cups of coffee a day will make you healthy: how to drink it? How do you drink it?

Professional baristas exchange please follow the coffee workshop (Wechat official account cafe_style) [the function of coffee burning fat] recently, many health food (specific health food) certified coffee drinks on the market, and declared that "coffee has the effect of burning fat", I believe we are no stranger to it. The effect of coffee on burning fat is known to be due to the caffeine and bleaching of coffee.

- Next

Professional coffee roasting | Crash/Flick is inevitable even in pure hot air.

For professional baristas, please pay attention to the topic of coffee workshop (Wechat official account cafe_style). Frankly speaking, it doesn't make much sense, but I did try and failed. I want to say that opening the throttle door before an explosion, on the one hand, exhaust smoke, on the other hand, if you quickly take the moisture away from the explosion, you may be able to ease the phenomenon of RoR Crash, of course, the air temperature can not be lowered as the wind volume increases.

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?