Professional coffee roasting | Crash/Flick is inevitable even in pure hot air.

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

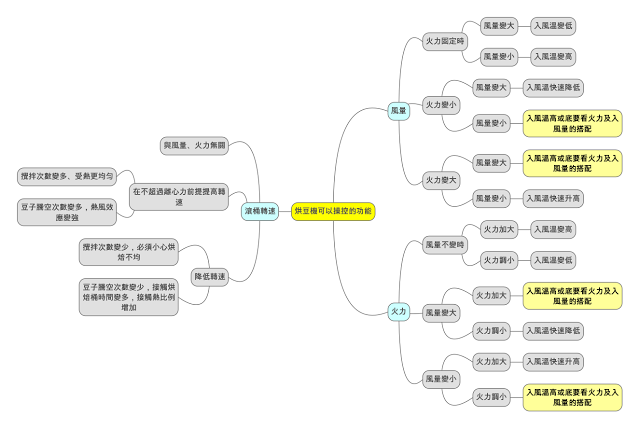

Frankly speaking, this topic does not make much sense, but I have indeed tried and failed. I want to say that opening the throttle before an explosion, on the one hand, exhaust smoke, on the other hand, if you quickly take away the moisture of the explosion, you may be able to ease the phenomenon of RoR Crash, of course, the air temperature should not drop too low because of the increase of the wind volume. The result of the empirical study is not obvious.

In addition, I also wondered whether it would be possible to avoid Crash/Flick if I reduced the baking volume, adopted a fixed windgate and only controlled the fire, just like the Probat 5Kg with a fixed throttle in the German SCAE contest. The empirical results showed that the effect of running three pots was good. Therefore, there is still no conclusion as to whether it is easier to control the Crash/Flick phenomenon by increasing the hot air ratio.

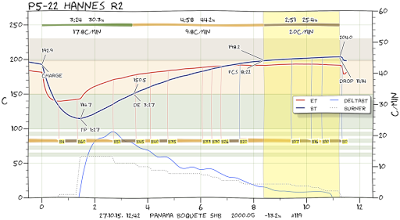

The curve of the second place Hannes in the 2015 German SCAE Competition

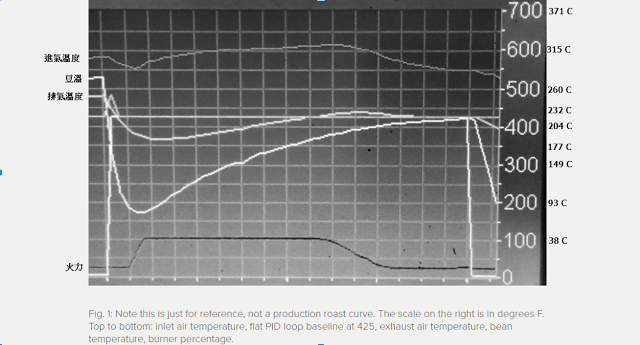

Previously, I wrote an article entitled "IKAWA is a blockbuster" mainly because it can be highly reproduced only by monitoring the discharge temperature without being affected by the external environment. Rob Hoos even wrote a blog for it and hoped to apply the sample curve of IKAWA to the mainframe of Loring. Because the exhaust temperature and so on at the same time beans and its baking environment finished a number, is a complex result, Rob Hoos in his Blog only mentioned that the farther the bean temperature from the exhaust temperature, the larger the RoR, the nearer the RoR, and attached two curves of Loring to help explain, and these two curves are also a few can google to the Loring curve, Loring this hot fan makes people feel very mysterious.

Loring curve of Rob Hoos

Because there is no chance to contact, I have always wondered whether the operation concept of Loring roller hot fan is very different from that of semi-hot air and straight fire roller machine. In fact, there are examples in this book on hand.

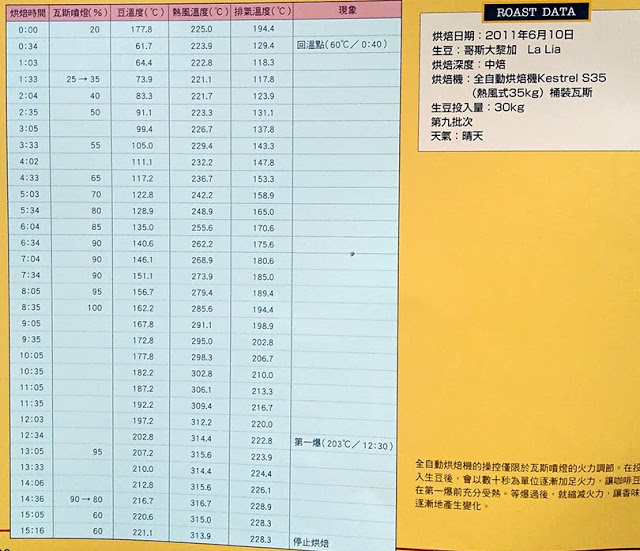

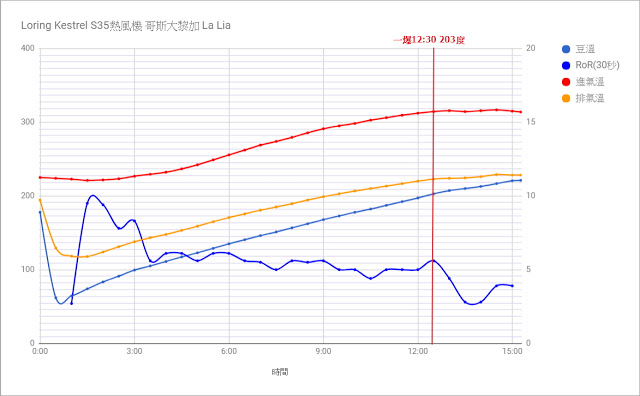

Record of Loring Kestrel S35 baking Costa Rican La Lia

Looking at the figure in the table above, famous Japanese stores use a low heat to dehydrate and do not have full firepower until the yellow dot. The rhythm of Slow Start Fast Finish (SSFF) is baking, which is very different from the curve of Rob Hoos (maybe it should not have been compared at all). It is not easy to see the clues just by looking at the numbers. I drew the above table into the following picture.

This is finally a little interesting, at least it solved my myth, the whole hot air can not automatically rule out the Crash/Flick phenomenon, how can I think that increasing ventilation before an explosion will help? however, this famous Japanese store controls the inlet temperature and exhaust temperature difference at almost the same range, which is also a very interesting phenomenon.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Professional coffee roasting | adjust the air only, not the fire, or just the heat?

Exchange of professional baristas Please follow the coffee workshop (Wechat official account cafe_style) Home-barista this discussion is worth a look at [Air flow in roasting], starting with Scott Rao's correct airflow, how Giesen judges airflow is at theright level, and then induces Rich to talk about more airflow m from a professional point of view.

- Next

Professional coffee roasting | SSFF/FSSF and coffee flavor

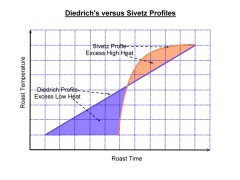

Professional barista communication, please pay attention to the coffee workshop (Wechat official account cafe_style) did not quite understand the main points of this picture expression, now this time, seems to understand some, in principle, this picture is to facilitate comparison, after a simplified diagram, not the real measurement record blue straight line is the use of Diedrich roaster, baking 16 minutes of bean temperature curve, because the RoR is fixed

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?