Royal Coffee Raw Bean Archives| Roasters, buyers and producers

The final step in a coffee drying plant is to make a final classification of raw coffee beans according to the number of items of coffee, and then bag them for export. The machine for classifying the number of coffee items is very large, divided into several layers, each tilting slightly downward. When the coffee enters the machine, the machine begins to vibrate, and the raw coffee beans with different mesh are screened out by gravity. The workers picked up the screened coffee beans in sacks at the bottom of the machine. Through multi-layer screening, the number of coffee beans selected is more accurate, and these devices can also be manually adjusted. I had the opportunity to disassemble and reassemble the machine with local workers in Zambia. But the parts he needed were out of stock, so we had to spend the whole afternoon adjusting to make sure the maximum number of holes was at the top.

In fact, this kind of machine is not very complicated, but a lot of metal parts are put together to remove debris from the coffee by vibration. But not really. When I visited Henrique Sloper, the owner of Camocim in Pedra Azul, Espirito Santo province, Brazil, I saw his coffee sorting equipment. You can see its exquisite organ-like design in the following picture.

Naming convention

Coffee beans measure the number of coffee eyes through the round holes of the sorting equipment. These round holes are usually measured in one-inch 1canap 64. The so-called 16-mesh coffee beans are 16cm 64 inches in diameter, or 1ax 4 inches in diameter. This is basically a global standard, some countries directly use the number of items to name beans, while others use some special names to correspond to the corresponding number of items.

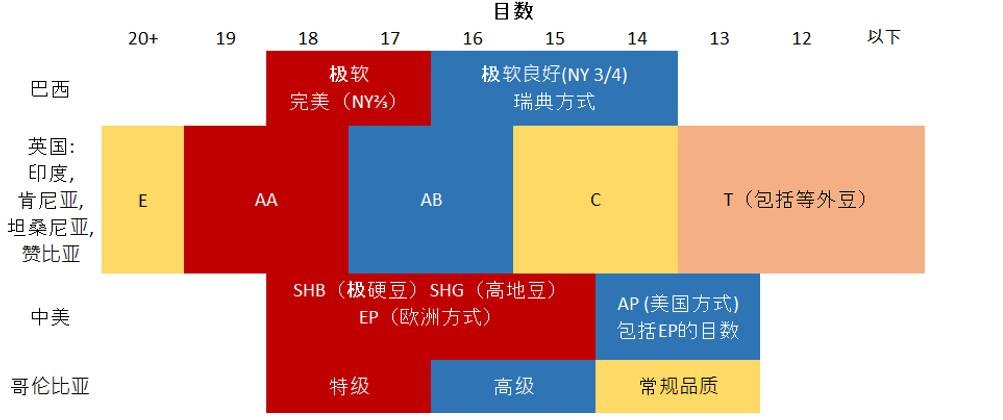

Some former British colonies in East Africa (such as Kenya, Tanzania, Zambia, etc.) are used to distinguishing coffee by table names, including India, which use the so-called British classification system, using the letters A, B, C and T to classify coffee. In Colombia, the taxonomic names are Supremo and Excelso, while in Brazil, Fine Cup and N2Unip 3 are used. In Central America, EP (European way) is used, and few countries use AP (American way) to name the classification. In addition, SHB (extremely hard beans) and SHG (highland beans) are also used to mark the highest grade of coffee beans. In addition, high-quality coffee in Brazil is labeled SS (extremely soft) to indicate the taste of coffee (such as softer), as well as softer beans or lower elevations.

Each classification basically stipulates its own fault tolerance ratio, that is, the proportion of coffee beans that does not belong to this range. EP allows no more than 5 per cent of coffee beans under 15 mesh, while AP is more relaxed, up to 100 per cent and 13 mesh. The Colombian Coffee Growers Association once stipulated that 5 per cent of Excelso grade coffee is not allowed in 13-14 mesh, and the classification criteria were later revised to strictly stipulate that only 1.5 per cent of Excelso allowed less than 14 mesh.

It may be a bit confusing to discuss different definitions in this area, and to illustrate it more clearly, I made the following comparison table:

Is this classification really important?

All this information may eventually point to a key issue. Of course, this question really can not be generalized, there is no absolute yes or no answer. This method of classification based on the number of items depends on several factors; in the traditional understanding, the number of items of coffee will greatly affect roasting, from this point of view, the answer is yes. But looking at it from other angles, there are many exceptions. Let's take a closer look at:

Large size means high price.

Globally, the size of coffee beans is directly related to the price of coffee beans; in many markets, the size of coffee beans is an important factor in determining prices. This is related to some traditional ideas that the larger the particles of beans, the higher the quality. For example, the price of a Kenyan AA is usually higher than that of a Kenyan AB. From the current understanding, this view may be a little out of date. But it is still used in many organizations, such as ITC (International Trade Center) and ICO (International Coffee Organization). As stated in the ICO literature, "using this classification based on the number of coffee orders, there is a certain basis that coffee beans at higher altitudes are denser, while beans with larger grains contain more substances, so they are of higher quality than beans at lower altitudes. Similarly, coffee at high altitude grows more slowly and therefore contains more flavor substances. "

Under these conditions, the smallest beans are generally screened out and sold as low-quality beans at a low price. In addition, very large beans (sometimes called elephant beans) are also screened out as low-quality coffee. However, there are exceptions, through this large bean has spawned a new variety, namely the Pacamara variety, more than 50% of the coffee beans are more than 19 orders.

In fact, this is not entirely true, and there will be exceptions. According to some studies, large coffee beans tend to grow at high elevations and in shade, while other studies claim that high-altitude coffee is smaller, more nutritious and denser. Such beans are higher-quality coffee. Interestingly, it is difficult to grow large coffee beans in many parts of the world, such as Narino in Colombia, southern Rwanda, and all over Ethiopia, where coffee beans are usually small particles.

Ethiopian coffee beans are recognized as the highest quality coffee in the world's boutique coffee field, but the coffee produced here is without exception small particles.

In our products, more than half of the coffee is 15 mesh or smaller, about 20% is 14 mesh or smaller, and about 36% is very small. According to the traditional grading standards in many countries, almost 1/4 of our coffee is disposed of and cannot be sold. But these coffees can get good results in the process of cup testing.

Some countries have changed their minds and turned the beans into an available advantage. In Tanzania, for example, round beans are sorted out and sold at higher prices. In coffee grading, the treatment of round beans is also very interesting, and it is often treated as small particles or defective beans. In fact, this is a phenomenon of genetic variation, that is, in coffee cherries that are supposed to produce two seeds, the cells do not divide and produce only one round seed. Some people say that the seed particles absorb more nutrients, so the flavor should be better, but this claim has not been confirmed by science. Others say that coffee beans of this shape will make coffee roasting more difficult if mixed with ordinary coffee beans. But in either case, round beans are valued by people. People have even made special equipment for screening round beans, and the screen used to screen round beans is oval rather than round.

Effect on Baking and Flavor quality-- theoretical comparison and practice

When it comes to the effect of coffee granules on roasting, it can change the thermal efficiency of the roasting process. The most important of these is the change in thermal effect and heat absorption due to the shape and size of coffee beans, which is what many professionals call "the ratio of surface area to volume". In short, coffee beans of different shapes and volumes react differently to thermal effects. In fact, whether unified large-volume particles or unified small-volume particles have little impact on baking, because whether large or small, the volume and surface area of the whole batch are basically the same, so it will not affect baking. What is more difficult is that when coffee beans of different sizes are mixed together, it will have an impact on baking, because it is difficult to unify the roasting degree of coffee beans of different sizes in the same batch roasting process.

We want to test the effect of coffee particle size on roasting: 1. Whether there are differences in the quality of coffee beans with different particle sizes; 2. Whether coffee beans with different particle sizes will have a serious impact on roasting.

We chose a coffee with a score of 87 from Vivette Nanguo in Guatemala in May as a sample. This coffee has a very uneven particle size (about 11% 13-14 mesh) and a slightly higher average water content (12.4%). The following picture is a pie chart of the particle size distribution of this batch of coffee.

My colleague Jen Apodaca first experimentally baked a batch and then baked the samples without much firepower adjustment. The following figure shows the baking curve.

With the sample baking curve, Jen bakes the selected samples, small particles (14 mesh and less), medium particles (15-17 mesh), large particles (18 mesh and above), and standard 16 mesh batches respectively while maintaining the same firepower as far as possible. The following is a pie chart of the mesh distribution of all five baking batches.

The following figure shows a comparison of five different baking batches

Given the baking of these five batches, the baking curve can be divided into three trends: the first group is unclassified and medium particles, the two batches have almost the same baking time, and the flavor development time after explosion is also very consistent. The second group is the batches of large and small particles, both of which heat up rapidly after an explosion. Finally, there are 16-item batches, which bake about a minute and a half faster than unselected batches. Interestingly, the baking time varies with the size of the particles, but the post-explosion flavor development time of the 16-mesh batch and the unscreened batch is very similar, which is 23.7% and 23.6%, respectively.

Different mesh sizes still seem to have some effect on baking. It seems that the greater the difference in the number of coffee particles, the longer the baking time, and the difference in particle size increases the baking time. The difference in the number of baking batches in the first group is the largest, so the baking development time is also the longest. The 16-eye one is the most neat, so there is no procrastination.

In terms of flavor performance, the 16-item batch was at least 1 point higher than other batches. The scores of large particles and unscreened batches were the same. The medium granule has the lowest score.

In addition, I am also interested in the effects of different particles on cooking and extraction. The coffee roasted in unscreened batches was screened and classified again according to the number of items, and compared with the roasted batches that had been screened. The following figure is a pie chart of the mesh distribution of baked particles.

Nearly half of the coffee cannot pass through the largest hole. I screened out six categories, greater than 19, 18, 17, 16 and less than 15, as well as mixed batches as samples. Using 11g beans, grind degree 8.5mm EK-43 grinder, 176ml 95 degree hot water, using VST LAB Coffee 3 concentration meter to measure 15 minutes after extraction.

To my surprise, there is no absolute difference in the comparison value. Through observation, Socratic Coffee also found that the data of VST could not be displayed very accurately, so it was possible that the difference between my experiments was ignored by the equipment. After passing the instrument measurement, Evan and I tasted different coffees again, and we both agreed, preferring small batches. However, in terms of extraction, the size of the number of eyes did not affect the extraction, at least the instrument did not measure the difference.

Conclusion theory

First of all, I would like to declare that my experiment is not very formal and rigorous, so this conclusion cannot be used to summarize all the phenomena, but at least it can be used as an example to illustrate the effect of coffee order on the thermal effect of coffee roasting. I think the difference in the number of coffee items will have a great impact on the endothermic effect of coffee roasting, but different numbers of coffee roasted in the same batch will not have a serious effect on the extraction. In any case, the way coffee is classified will definitely have an impact on the market value of coffee.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Before 2011, the Blue Mountain Coffee in the Chinese market was all fake Blue Mountain!

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style). Yes, this is a screenshot of the official website of CIB (Blue Mountain Coffee Association of Jamaica). Click on the Chinese Rooster Club to have several photos and a PDF file. Blue Mountain Coffee will be shipped to China for the first time on April 5, 2011. this transaction will be made by Zhejiang DUNNS RIVER Import and Export Trading Company.

- Next

Explore the source of the great flavor of Hawaiian Kona coffee Kona Coffee

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style) what is the link between Hawaii and coffee? Hawaiian Islands, a group of islands in the north-central Pacific Ocean. The Hawaiian Islands, also known as the Sandwich Islands (Sandwich Islands) between 1778 and 1898, are part of Polynesia and are made up of 19.

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?