Professional coffee roasting | Why can't other people's baking curves be copied?

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

Rob Hoos wrote a great article on The Roast, which was shared on Home-barista and aroused a warm response. The title of the article is "Understanding th Limitations of Thermocouple Readings".

Although I want you to read it for yourself, on the one hand, the weight of the text is not small, on the other hand, he really mentioned several important ideas, afraid that everyone will miss it, or spend some time to do some small collation.

First of all, let's talk about an important phenomenon: "Why can't other people's baking curves be fully trusted?" "it's not that we get fake data or incomplete data, but the thickness, length and installation location of the temperature probes that produce those curves have too great an impact on the acquisition of temperature numbers. As long as we change the machine and change the probe, the data becomes completely meaningless. Rob has been describing this difference throughout the article. Let's take a look at a few graphs first.

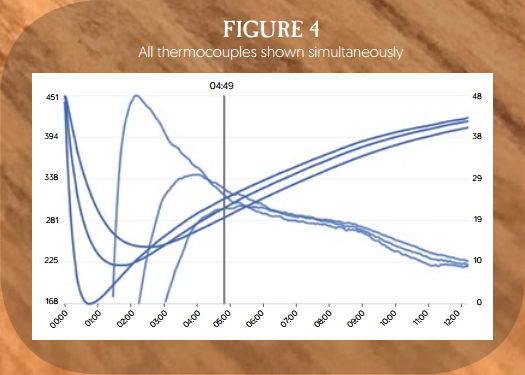

After combining the three pictures of Figure on 1-2-3, the following is Figure 4

When the above three curves are put together, it can be found that the important recovery points are 47 seconds, 1 minute 46 seconds and 2 minutes 43 seconds respectively, and then the RoR varies so much that it makes people think that it is the curve produced by three different pots or even three different machines. In fact, in order to demonstrate the influence of temperature probe specifications on the temperature curve, Rob installed the following temperature probes of different thickness in the same position on the same machine, and made a measurement record on the same pot of beans.

Probes of 1.6,3.2, 6.4mm from left to right

Three probes of different thickness are installed on the lower bezel of the Loring bean dryer.

We skip the principle of probe temperature measurement for a moment. When we see the graph above, we should be able to understand why the temperature curve becomes meaningless as long as the machine is changed. Because different probe specifications alone can cause such a big difference, coupled with the installation location, in-depth baking bucket length and other factors, the difference will be magnified. This is also the previous time when Fika Fika James shared the baking information of 75Compare 85, I pointed out that there are a lot of key things missing in the slide, and you must have a bottom line when you watch it.

Rob asks you a question: "what temperature is measured by the bean temperature stick buried in the bean pile?" "

1. The temperature of the bean pile

2. The temperature of air + bean pile

3. The temperature of the air

4. the temperature of the bean temperature.

After the above illustration, I say the correct answer is 4. The temperature of the bean temperature bar, everyone's recognition degree should be relatively high. The temperature returned by the bean temperature bar is its own temperature, especially near its tip, not the real temperature of the baking bucket air, nor the real temperature of the beans. So how does the temperature of the bean temperature be affected? It doesn't seem to be as simple as we thought. The thickness of the shell of the bean temperature bar, the position of the bean temperature bar in the dryer, the situation buried in the bean pile, the amount of beans, the air passing through the bean pile, the flow rate of air, the adjustment of flame, and so on will affect the temperature of the bean temperature bar. The temperature number of the bean temperature bar can only be said to be an alternative to the actual bean temperature, and it is greatly affected by the above factors.

The reading of the bean temperature rod is affected by its shell size. Rob did an experiment, soaked the temperature probe of the aforementioned 1.6/3.2/6.4mm in boiling water, and then took it out to measure the time when it returned to room temperature. 1.6mm was the most sensitive. After taking out boiling water, the temperature fell quickly, and the sensitivity of 3.2mm was the second, and after 5 minutes, the temperature caught up with 1.6mm 's, and returned to room temperature in about 9 minutes. 6.4mm had the slowest reaction and did not return to room temperature after 10 minutes.

The reaction rate of temperature measuring rods of different thickness from boiling temperature to room temperature

The curve of the temperature measuring bar with fast reaction will be bumpy, and the curve with slow reaction will be smooth and good-looking. as far as roasting coffee is concerned, we pursue the flavor of coffee, not a good-looking curve, but too sensitive reaction will also cause interference in operation. you can make a choice when you look at the actual application, and there is no best standard answer.

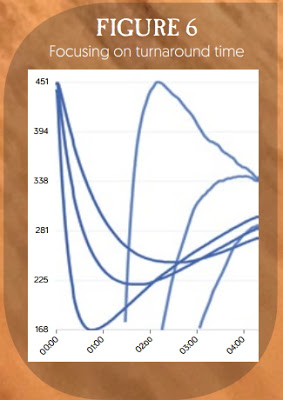

How does the temperature recovery point come from? there will be no temperature recovery point without preheating. In order to stabilize the baking environment, we will preheat the baking machine before baking, then put the raw beans at room temperature into the baking, and then the bean temperature bar will be cooled by the incoming beans, and the reading will drop rapidly. while the bean temperature bar cools down, the beans are also rapidly absorbing the heat from the baking room and heating up rapidly. When the temperature of the bean temperature bar is equal to the theoretical temperature of the bean pile (RoR = 0), it is a state of equilibrium between the bean pile and the bean temperature bar (not the equilibrium between the bean and the bakery environment). That point is the temperature recovery point, after which the bean continues to heat up, and the bean will no longer cool the bean temperature bar, and the bean temperature bar will heat up with the bean (RoR > 0). Different specifications of bean temperature bar and bean pile temperature balance point and the subsequent heating rate are quite different, the thinner the more sensitive, the lower the drop and the faster the climb, as shown in the following figure

What is the effect of bean temperature bar reaction rate on the heating curve (RoR)? Today's baking is very accustomed to RoR's help to us, because it is a leading indicator of bean temperature change and can help us maintain the consistency of flavor between the furnace and the stove, but only focusing on RoR is a bit biased. We can move our eyes a little further and put it on the incoming temperature. (voice: Rob's Loring has incoming temperature, but do you and my machines? I have my own add, and so do the American labeling machine Mill City of GYR in China. If the probe is too thin, its temperature may be higher than the actual bean temperature at the end of the baking, and the slight adjustment of firepower will be reflected in the RoR. Relatively, the thicker probe does not have this phenomenon. Some people have developed a set of their own Max RoR to avoid baking errors, and Min RoR to eliminate the loss of temperature after explosion (stall) or insufficient heating to produce baking, but this is completely dependent on the specifications of the machine and the use of probes, so it is difficult to transfer the experience of numbers.

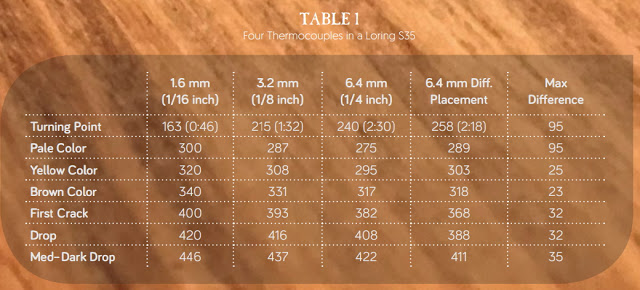

The following table shows the temperature figures of different thickness temperature probes in each baking stage (Fahrenheit). If you look at the temperature recovery point alone, there can be a difference in 163F~258F (72C~125C), which is really huge.

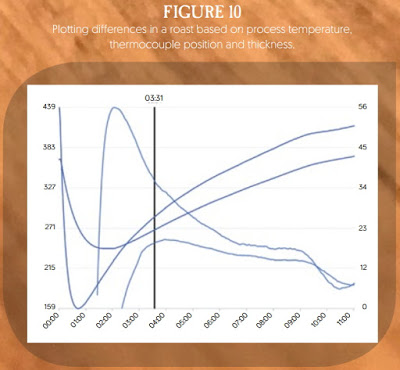

If the probes of different specifications are placed in different positions of the machine at the same time (one on the lower dou plate and the other on the upper left of the lower dou plate), the curve is as follows, there is no place to discuss together.

Conclusion:

★ can consider using a thin probe and placing it at a lower level relative to the rolling barrel, such as on the lower bean mouth plate (Loring's empirical experience)

★ remembers that the digital measurement of the bean temperature bar only measures its own temperature, but it just can't get an alternative number of the real bean temperature. It is affected by factors such as the specification of the bean temperature bar and its installation location, so it cannot be applied to other machines.

★ each person's machine, style, customer base and temperature probe will be different, so it is best not to compare.

★ enjoy the complexity of baking and the fun in it.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee producing area characteristics of Indonesia West Java coffee flavor

Professional baristas Please follow the Coffee Workshop (official Wechat account cafe_style) when it comes to Indonesian coffee, the first impression is mellow and unique wet planing. Java, the oldest producing area, continues its reputation from the glorious era of Indonesian coffee in the 18th century. When it comes to Java coffee, it is still reminiscent of high-quality delicacy, and the most famous mix at that time was

- Next

The difference between hand-brewed mocha coffee and Italian mocha coffee What coffee beans are used to make mocha coffee

Professional barista exchanges, please pay attention to coffee workshop (Weixin Official Accounts cafe_style) Mocha coffee is probably the most popular coffee variety among girls, due to its strong chocolate flavor and milk flavor. Most people who know a little about coffee will think it just adds chocolate to latte. This statement is not wrong, but it is not entirely true. That's a term that refers to mocha as

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?