Adjustment and grinding of mini porlex portable bean grinder thickness adjustment of mini porlex bean mill

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

This mini porlex and stupid dad coffee filter rack is the perfect combination to go out to make coffee.

Even the original Japanese packaging emphasizes carrying "convenience".

Some articles that have been written before to adjust and grind the scale are also messed up because of the blog backup and moving, which are specially sorted out as follows.

Ha! the cursor caliper that has not appeared for a long time ~ ~ first explain that if you open the lower powder cartridge and the upper half of the bean grinder, you can see the thickness adjustment button and ceramic grinding mortar. This bean mill is easy to carry, hand-held grinding force, and ceramic cleaning is easy. In fact, there is no need to wash each time the powder cartridge and the upper bean grinder knock each other on the stainless steel part. You can knock off the residual powder ~ ~ silly dad uses dozens of pounds of stainless steel and there are no knock marks (ok can be knocked on each other moderately)

Painless adjustment

Due to the problem of dimensional accuracy in the ceramic production process, the bean grinder will produce a sloshing gap (grinding process) between the ceramic mold mortar and the fixed parts of the grinder. So stupid dad used some filling materials to fill these gaps.

1. The gap between the inner conical grinding mortar and the plastic base is fixed, and the paraffin sealing film is used to wrap the plastic base. In fact, small tape or water-proof silicone tape can be used.

two。 The outer molar ring is fixed with the upper grinder, using a small red rubber band or the inner ring of the tire.

Adjustment part: the paraffin film is cut into 1.2cm (W) * 20cm (L), the plastic base is wound with paraffin film around the upper half of the base about 3'4 times, and the rest of the paraffin film is wound around the bottom of the base, not too many circles, otherwise it will be stuck.

Put a red rubber band on the outer ring of the grinding mortar and insert it into the fixed seat.

After the above adjustment departments eliminate the tolerances and install them back.

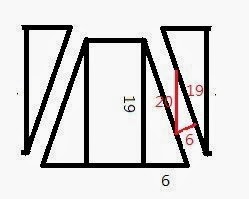

The adjustment knob is metric M6 standard screw pitch is 1mm; and rotate one circle of upper and lower pitch 1mm

The taper of the internal grinding mortar is 19. 6; after conversion ~ ~

If the adjustment knob is turned up and down 1mm (20), the inner and outer grinding plate will be vertically spaced with 0.3mm (6); so we will tighten (the upper and lower grinding plate will not move) or retreat 10cm 12 grids (8 squares is a circle), then it is about the grinding particle size of 400~450um, which is suitable for hand punching or Syphon grinding thickness.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Standard for espresso bean grind fineness How to determine espresso grind powder-water ratio

Professional barista communication, please pay attention to coffee workshop (Weixin Official Accounts cafe_style) freshness is the first requirement of good coffee, the second important thing is to master the grinding thickness of coffee beans, which directly affects the extraction effect, that is, the quality and intensity of coffee flavor. In principle, the finer the coffee powder, the longer the brewing time, the stronger the coffee taste; conversely, the coarser the coffee powder, the shorter the brewing time,

- Next

Grinding-the difference between a hand grinder and an electric grinder Coffee grinder Scale thickness

Professional barista communication please pay attention to coffee workshop (Weixin Official Accounts cafe_style) grinding-hand grinder grinding is a key factor affecting coffee flavor, grinding thickness needs to cooperate with different brewing methods, grinding degree of different thickness, in order to brew good coffee, grinding time is more important, coffee beans are stored in the way of cooked beans, before brewing, grinding can be carried out again

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?