Ethiopia Yega Sheffield Gaidi Ocochelbanco G1 sun Fafat flavor?

Professional coffee knowledge exchange More coffee bean information Please pay attention to coffee workshop (Weixin Official Accounts cafe_style)

Ethiopia's Yegashefi region| What's a sunfaust?

Ethiopia Washed Yirgacheffe Banko Fufuate G1

Ethiopia Yega Shefi Gedi Okochirbanke G1

Treatment Plant: Benafica Treatment Plant Beyene Figa

Altitude: 1900 - 2100 m

Breed: Native local variety (Heirloom)

Annual rainfall: about 1800 - 2000 mm

Treatment: sun, African shelf drying

Ethiopia is a country known for the quality of Arabica coffee, and the Gedeo Zone of Yegashefi is known for its premium coffee, grown by small farmers. The mountain villages of Yegashefi are foggy all the year round, breezy, cool but not hot, and rainy but not damp. The original yeghashefi coffee tree was planted in the mountains by European monks, but now it is mostly planted in farmers 'own backyard or mixed with other crops in the farmland. The yield per household is not much, and it is a typical pastoral coffee. Yerga Sheffi is mostly washed to retain its freshness and cleanliness, but a small amount of fine beans are deliberately exposed to the sun to enhance the charming fruity flavor and body.

Kochere is one of the 77 Woreda (Ethiopian administrative regions) of SNNPR Ethiopia, and in the coffee domain, Kochere is part of Gedio Gediyo in Yirgacheffe and is one of the most important growing areas of Yirgacheffe. Cochere can be divided into several micro-regions, and the coffee produced in the region is sometimes named after the town of origin.

The Benafica processing plant acquires cherries from about 600 smallholders in the adjacent area, planted at an altitude of about 1900-2100 meters, which is quite excellent. The cultivation of smallholders follows the traditional Ethiopian method and is fully organic. The "African High Shelter" design, with legs to avoid moisture and dirt impurities on the ground, and air convection to make coffee fruit more ventilated, dry and uniform. Solarization does not require too many tools and equipment, and does not require water except for the step of removing floating beans. The cost is relatively low, and it is widely used in areas where water resources are not abundant and less abundant.

Coffee cultivation is mostly based on the pastoral coffee model, in which coffee farmers grow their own coffee trees near their living areas and harvest them during harvest season, then send them to nearby water-dependent processing plants for centralized processing (or centralized acquisition by middlemen). Except for a small number of plantation estates that have the strength to plant, pick and process coffee beans independently, coffee beans from many different regions and varieties will be processed centrally by the processing plant and then sent to the auction house for official evaluation and grading. This is why many Ethiopian coffee beans are named after the processing plant or cooperative, and it is also one of the reasons why the same batch of coffee beans is mixed with multiple coffee varieties, and even the flavor of different batches of coffee beans produced by the same processing plant can be significantly different.

Elevated bed solarization:

1. Harvest ripe coffee fruit

2. Preliminary selection of impurities and inferior beans

3. Screening floating beans: Pour coffee cherries into the sink. The ripe and full fruits will sink to the bottom of the sink, and the immature or incomplete fruits will float to the surface.

4. Sun drying: the sink in the bottom of the mature coffee fruit out, spread in the sun drying field, the moisture from 70% to 10-12% or so. The fruit should be turned several times a day to air dry evenly and covered at night to avoid moisture.

5. Dehusking: After about two weeks to four weeks of exposure, the outer layer of coffee seeds has dried, and then use a huller to remove the shell.

Breed:

There are too many native species in Ethiopia. It is like the natural gene bank of Arabica. On the one hand, there are many varieties and it is difficult to identify and classify them. Therefore, they are collectively referred to as "Heirloom Native Species". There are long particles, there are also small particles, the shape is relatively round, the bean body is very small, mostly between 14-15 mesh.

[Raw beans, baking]

Get this bean, raw beans are yellow-green, silver skin attached to the surface, with fresh wine fragrance and strawberry aroma, density is larger, water content between 10-11%, try baking two curves for comparison.

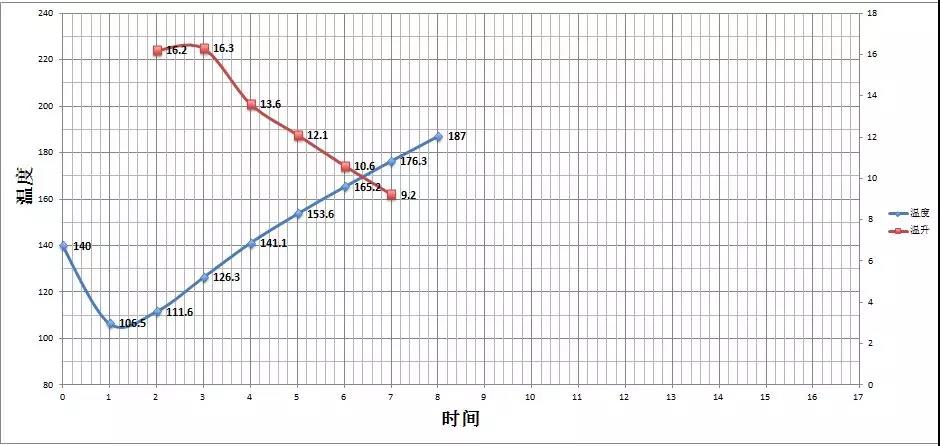

Line 1:140 degrees, 30 seconds later, fire to 130, damper to 2.5, return temperature point at 1:13 seconds, yellow point at 4:42 seconds, damper to 3.5 at 160 degrees, fire unchanged, 170 degrees and 180 degrees, fire from 100 to 70;7:30, start explosion, temperature 181.5 degrees, damper fully open 5, 1:28 seconds after explosion, exit temperature 193. It belongs to quick fry baking. (Below is the baking curve for #1)

Line 2: At 140 degrees, fire to 100 in 30 seconds, throttle to 2.5, warm to 1:14 seconds, yellow to 4:40 seconds, fire to 80 at 120 degrees, throttle unchanged, fire to 100 at 155 degrees, throttle to 3.5; fire to 120 at 175 degrees, fire to 60 at 190 degrees, throttle unchanged, explosion at 8:50 seconds, temperature 186 degrees, 1:50 seconds after explosion, temperature 191 degrees.

Observation of baking records shows that the overall temperature rise of Line 1 is relatively fast, and the temperature rise per minute after dehydration is maintained at about 12 ℃, the development time of first explosion is short, the caramelization reaction is less, and more flower fragrance is retained; Line 2 adopts steady temperature rise, and the fire power is increased before the first explosion.

[Cup Test Comparison]

Line 1:

In the cup test, dry fragrance shows citrus sour fragrance, wet fragrance has obvious caramel, fruit fermentation aroma; when sipping, you can immediately feel the flavor of berry, citrus, orange, sour and sour shock, after the temperature drops, peach, sucrose sweet feeling appears, black tea aftertaste, juice taste, overall clean balance.

Line 2:

In the cup test, there are also citrus, dark plum sour, acid weaker than line 1, with dark chocolate, cocoa flavor, but the latter section has a slight bitter taste, smoky taste, taste slightly deficient, swallow the mouth has a "dry feeling"; Increase the fire before explosion, although it can provide enough heat for caramelization reaction, but also the heat of the skin is too late to transmit to the bean core, causing the bean surface to burn, causing bitterness, prolonging the baking time, but also grinding off part of the sour taste.

[Brewing Test]

Line 1 scores high, give priority to brewing, see if it is similar to the cup test results

task 1:

Parameters: V60 filter cup, 90 degrees, BG 5R (64% pass rate of No.20 sieve in China standard), powder-water ratio 1:15, time 2:03 seconds

Technique: 21-127-227g, 21g of water steams for 30 seconds, the first stage of water injection is small water flow to 127g, the second stage is slightly larger water flow circle, 1:17 seconds for the second stage of water injection, water injection to 227g

Flavor: Bright and sour, but rough and astringent on the palate. Maybe because the water temperature is too high, or the extraction time is a little long, resulting in more astringency release.

task 2:(adjust water temperature)

Parameters: V60 filter cup, 89 degrees, BG 5R (64% pass rate of No.20 sieve in China standard), powder-water ratio 1:15, time 2:02 seconds

Technique: 21-125-227g, 21g water steams for 30 seconds, the first stage water injection small water flow water injection to 125g, the second stage slightly larger water flow circle, 1:17 seconds for the second stage water injection, water injection to 227g

Flavor: Compared with the first brewing, the sweetness of preserved fruit and sucrose increased obviously, but the latter stage did not last long.

task 3:(adjust water injection volume)

Parameters: V60 filter cup, 89 degrees, BG 5R (64% pass rate of No.20 sieve in China standard), powder-water ratio 1:15, time 1:55 seconds

Method: 21-125-227g, 21g water steams for 30 seconds, first stage water injection small water flow water injection to 125g, second stage than the first two brewing, increase water flow circle, 1:17 seconds for the second stage water injection, water injection to 227g

Flavor: berry, citrus, grapefruit, lemon, black tea aftertaste, fruit juice taste, thin texture, can clearly distinguish the taste, the second stage of rapid processing can reduce the extraction rate, light texture is easier to drink the taste.

Although the cup scale score, Line 1 is obviously higher than Line 2, but it does not mean that Line 2 is not good to drink, so we all brew the two curves.

task 1:

By baking records, Line 2 is relatively more baked than Line 1 and can be brewed at a lower water temperature

Parameters: V60 filter cup, 89 degrees, BG 5R (64% pass rate of No.20 sieve in China standard), powder-water ratio 1:15, time 2:00 seconds

Method: 20-125-228g, 20g water steams for 30 seconds, the first stage of water injection with small water flow to 125g, the second stage of water injection with large water flow, 1:17 seconds for the second stage of water injection to 228g

Flavor: At high temperature, the sour taste is stable, the astringency of black plum and grapefruit peel is obvious, the latter part is slightly bitter, a little smoky, similar to the taste of cup test.

Through the comparison of the two curves, the baking of Line 1 expresses the bright fruit flavor of Sunlight and Sherfie [Fafort]. According to the baking method of quick baking, V60 filter cup brewing test is carried out to find out the better brewing method of this bean, showing the characteristics that beans should have.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

What is Blue Mountain Coffee? What do you have in Jamaica Blue Mountain Coffee? What is CIB?

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) whether coffee lovers or not, have more or less heard of Jamaica's Blue Mountain Coffee; as soon as you open Taobao, it is also full of Blue Mountain flavor Blue Mountain mix these. What is so special about the Blue Mountains that makes people so impressive? Next, let's learn about one.

- Next

Tara Pearl, Costa Rica. Tobush Tobosi Manor in Red Honey. Carnett Manor washed in VS.

Professional coffee knowledge exchange more coffee bean information please pay attention to the coffee workshop (Wechat official account cafe_style) Costa Rica Tara Pearl producing area | Shumawa Manor, Tobush Tobosi Manor, Carnett Manor Mozart? Costa Rican coffee cultivation was introduced from Cuba in 1779 and exported for the first time in 1820. There are now about 32000 coffee farmers.

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?