The coffee roasting process introduces how coffee is roasted to highlight the desired flavor.

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style)

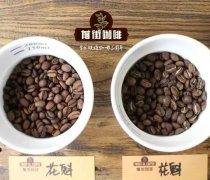

The whole roasting process of coffee from raw beans to cooked beans, STEP 1: from bean feeding to T.Point feeding is the initial stage of roasting. After the beans are put into the preheated drum, the drum temperature will drop immediately until the drum temperature and the bean temperature reach balance. Generally speaking, it is appropriate to reach T.Point (recovery point) within 120 seconds, STEP 2: from T.Point to Yellow

After T.Point, raw beans enter the endothermic stage. 70% of the bean weight is made up of insoluble (Insoluble) cellulose (Cellulose). In order to transfer heat to the inside of the bean, the water conductivity is used. If the bean water content is low, the time to reach the Yellow stage will be shorter, on the contrary, if the bean water content is high, the time to reach Yellow will be longer. STEP 3: from Mena reaction (Maillard Reaction) to 154. C

The baking temperature reached 154. At C (PS: every bean roaster will not be the same), the internal and external temperature and pressure of coffee roasting beans are at about the same stage. Sugar components are decomposed into reducing sugar (Reducing sugar) by adding water, which combines with amino acids (Amino acids) to produce Melanoidine and volatile organic compounds, which is the Mena reaction. Through this process, coffee beans will produce flavor changes. STEP 4: from caramelization (Caramelization) 160.C to 200.C

At this stage, beans are caramelized by thermal decomposition, which begins to reduce sweetness and transform into a very complex flavor (Aroma). At the same time, due to the increase of CO2 pressure and vapor pressure, the beans began to produce a fever reaction.

STEP 5: coffee roasting from the first explosion to 194Murray 5.C

When the vapor pressure and CO2 pressure inside the bean accumulate, the first burst (1st Crack) occurs. The "blow holes" produced at this time becomes the outlet for the discharge of Flavor compounds inside the bean. At this stage, the beans are completely converted to a febrile reaction. STEP 6: from the second explosion to 220. C

The CO2 pressure accumulated due to thermal combustion is released outward, and the beans burst again, which is called the "second explosion". At this stage, the cell structure of beans begins to be destroyed, and the interior begins to be coked or carbonized (Carbon). From then on, the flavors attached to Dry Distillation (Resin, Spice, Carbon) will appear and produce obvious bitterness.

STEP 7: from bean production to cooling (Cooling)

Although the beans begin to cool immediately after they are produced, the temperature of the beans will not drop immediately. Because the temperature inside the bean can be maintained at a high temperature for a period of time, the high temperature maintained by the bean itself may change the degree of baking and may lead to the volatilization of the aromatic flavor. therefore, rapid cooling is a very important step to maintain the flavor. After the coffee is roasted, the beans are forced to cool. Then carry on "raise beans", emit carbon dioxide, and the flavor is more mature.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

What are the classification of coffee varieties and what are the common coffee varieties?

Based on the classification of coffee varieties: ① according to large varieties, coffee can be simply divided into Arabica species and Robusta species. In general, Arabica tastes better than Robsta (it is not so simple to generalize). For example, we often hear a fast food chain claiming to use 100% Arabica coffee beans. But it is important to note that Arabica does not necessarily represent

- Next

Teach you how to read the coffee baking graph and learn the basics of roasting a cup of coffee.

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style)

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?