Coffee technology coffee roasting Roasting Skills training

SCAE has officially rescheduled the baking course, changing the previous Level1 and Level 2 to three levels: [Foundation Junior] [Intermediate Intermediate] [Professional Advanced].

[Foundation Junior]

Objective: to understand the basic knowledge of raw coffee beans; to understand the basic knowledge of roasting utensils and baking process; and to perform roasting according to a predefined roasting plan.

Content abstract: introduction of raw bean knowledge; introduction of baking machine; introduction of baking process; actual operation examination and written test.

1.01 knowledge of raw beans: varieties, treatment methods, planting altitude, classification, size, density, water content, content of various substances in raw beans.

1.02 roaster: main brand and model, type of roaster, mode of heat source.

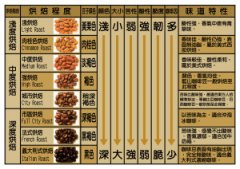

1.03 baking process: stage division and function of baking process; basic knowledge of heat transfer; color change of coffee beans during baking; information recording during baking; taste differences of different baking degrees; importance and common ways of cooling after baking.

1.04 actual operation test:

Three practical exams with a total score of 26 and passed with a score of 16 (60%)

Fuck 1:

a. Team: a group performs two baking according to the baking plan provided by the instructor and records the relevant information as required (60 minutes)

b. Individual: calculate and fill in the baking record form (10 minutes) according to A's baking record.

Practice 2: personal identification of baked samples at different baking stages (5 minutes)

Practice 3: personal identification of coffee cooked bean samples with different roasting degrees (10 minutes)

1.05 written test: 15 written questions were completed within 45 minutes, and 9 questions were answered correctly. The form of multiple choice questions and short answers.

[Intermediate Intermediate]

Objectives: baking curve understanding; baking defect identification and analysis; analysis of physical changes in baking; simple baking production management.

Content abstract: primary content review; baking process improvement; baking defects; daily maintenance of baking machine; baking production management; practical examination, written test.

2.01 Advanced baking process:

Detailed description of the mode of heat transfer in baking;

Changes (physical and chemical changes) of coffee beans during roasting;

Identification, cause analysis and avoidance of baking defects;

Factors affecting baking (machine, environment, raw beans);

Differences of coffee ripe beans in several typical baking curves;

The importance and common ways of cooling after baking.

2.02 Baking defect

Baked (relatively low temperature, long time baking.)

Scorched (relatively high temperature, scalded bean table.)

Tipped (relatively high temperature, scald bean end.)

Quaker (raw bean defects lead to uneven baking)

Burnt (relatively high temperature, baking for a long time, baking Chengdu is relatively deep, the throttle is too small, smoke exhaust is not smooth.)

2.03 daily maintenance of roaster: bearing lubrication; silver collector cleaning; flue cleaning.

2.04 baking production management: understand the equipment needed for baking production; raw bean storage conditions; food safety related; baking production example design.

2.05 practical test: four groups of practical tests, with a total score of 52 points, passed 36 points. practice 1: individual (or group, up to 2 people) 60 minutes

Use the baking chromaticity detector to measure the chromaticity value of the baked sample (coffee powder) provided by the instructor;

Bake a batch of beans to the same baking degree (the chromaticity error is within + /-4), and record the baking as required.

Practice 2: the weight loss, moisture content and volume changes of the baked cooked beans were calculated and recorded for 10 minutes.

Practice 3: personal 20-minute

Identify the baking degree according to the baked samples provided by the instructor;

The baking sample provided by the tutor is measured under red light to identify the baking degree.

Practice 4: individual 20 minutes, under the red light according to the baking samples provided by the instructor cup test, identify baking defects.

2.06 written test: 25 questions were completed in 45 minutes, and 18 questions were answered correctly. (form of multiple choice questions and short answers)

[Professional Advanced]

Objectives: advanced baking curve; advanced cup measurement and baking degree identification; baking production and business management.

Content abstract: review of baking process; coffee raw beans and roasting advanced stage; physical reaction in baking; chemical reaction in baking; baking degree identification; cup test correlation; baking business management; baking production management; practical examination, written test.

3.01 Review of the baking process: primary and intermediate review; three stages of baking; basic physical changes of coffee beans during roasting; stage changes in calories.

3.02 Coffee raw beans and roasting advanced:

Understand the impact of different treatment methods on baking;

Understand how to adjust the baking plan according to different raw bean processing methods;

Understand the possible germs and human hazards of raw coffee beans.

3.03 physical reactions during baking: heat transfer; evaporation of water; pressure change in raw beans (first explosion); heat transfer; volume change of coffee beans; changes in internal structure of coffee beans; weightlessness; silver skin; changes in gas emissions (before, during and after baking); changes in the physical structure of coffee beans (second explosion).

3.04 Chemical reactions in baking: pyrolysis reaction (Pyrolytic Reaction), Mena reaction (MaillardReaction), Straka degradation reaction (StreckerDegradation), caramelization (Caramelisation), hydrolysis (Hydrolysis), oxidation (Oxidation), decarboxylation (Decarboxylation).

3.05 baking curve: fast baking; slow baking; changes of moisture, organic acids and soluble substances in baking; setting baking variables.

3.06 roasting degree identification: coffee with the same roasting degree that can describe and distinguish different roasting curves in terms of flavor.

3.07 cup test related: basic introduction of cup test, triangle cup test.

3.08 baking business management: cost calculation, new product research and development, matching considerations.

3.09 baking production management: baking equipment planning; environmental safety considerations; production case planning (according to 5s specifications); baking equipment and material procurement planning; comparative analysis of online and offline recording systems; regular maintenance planning of baking equipment.

3.10 practical test

Five groups of practical exams, with a total score of 52 points and passing points of 42 points. practice 1: group, 150min, up to 7 stoves, baking 4 curves are as follows:

(1) preheat the roaster according to the temperature set by the instructor, fully open the baking sample to the second explosion and record the baking process.

(2) preheat the roaster according to the temperature set by the instructor, adjust the firepower before the explosion, raise the temperature at 10 degrees at the beginning of the explosion, record the baking and determine the color value of the baking degree.

(3) according to the requirements set by the instructor, carry out fast baking to achieve the baking degree in practice 2. If it is not up to the standard, there are two opportunities to re-bake .

(4) slow baking to achieve the baking degree of practice 2 according to the requirements set by the mentor. if it does not meet the standard, there is a chance to re-bake .

Practice 2: individuals, 10 minutes, through the visual guide to provide baked samples, baking color value identification.

Practice 3: individual, 20 minutes, cup test of 3 baked samples and standard samples provided by mentor under red light to identify baking defects.

Practice 4: individual, 20 minutes, use the WCE baking cup score table to test the 2 baked samples provided by the instructor, and briefly describe the baking improvement scheme.

Practice 5: individual, 20 minutes, cup test the 4 baked samples and standard samples provided by the instructor, and describe the differences.

3.11 written test: 36 questions were completed in 45 minutes, and 29 questions were answered correctly.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Roasting Technology of Fine Coffee beans Coffee Baking training and Teaching Summary

The principle and process of coffee roasting we must first understand that raw beans are hard seeds in coffee berries, such as water, chlorogenic acid, protein, alkaloids, caffeine, fats, sugars and so on. While baking at high temperature, the above substances will undergo chemical changes such as Mena reaction and Stryker degradation, resulting in coffee tannic acid, nicotinic acid, aromatic esters, alcohols,

- Next

Roasting technology of coffee beans roasting methods of fine coffee

For a long time, the production of coffee has been improved by increasing the yield and reducing the difficulty of planting according to the economic factors. However, with the promotion of boutique coffee, the nature of coffee has also changed, from the trend of economic priority to allowing consumers to enjoy better quality coffee. More and more people are willing to buy high-quality coffee beans at a high price, or even go to the producing area in person to upgrade from cultivation to quality.

Related

- What is the meaning of lactic acid fermentation with coffee bean treatment?

- How to judge the state of foam by sound?

- How does the latte pull out the unicorn pattern? Come to get for a little trick to improve the flower pull!

- Will flower pulling affect the taste of the latte?

- Do you know the history of coffee?

- The difference between honey treatment and sun washing what is raisin honey treatment?

- What kind of milk can a novice use to make coffee foam to keep the foam longer? The correct method and skills of milking tutorial sharing

- Why do washed coffee beans taste sour? Flavor characteristics of washed Coffee

- Introduction to the skill of how to practice the size and height of water injection around the circle of hand-brewed coffee

- How do beginners practice coffee flower drawing from scratch?