Structure principle of E61 brewing head of Faema E61 coffee machine

The E61 head first appeared on the Faema E61 coffee machine in 1961. It is an exquisite design and has become a classic of the Italian coffee machine. Nearly 50 years after its birth, there are still many Italian coffee machine manufacturers assembling this kind of head on some models of machines.

What are the advantages of E61 boiled head to make it popular for such a long time? Here we quote the materials on home-barista.com to make a brief introduction to E61 cooking, hoping to be helpful to those who want to understand the structure and principle of E61 cooking head.

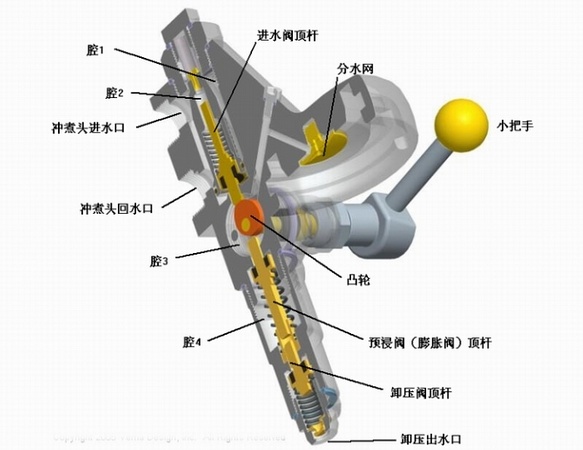

First of all, let's take a look at the section of E61.

Unlike the ordinary cooking head, the E61 is connected to the boiler (or heat exchanger) with two water pipes, the upper one is called the inlet and the lower one is called the backwater outlet. The hot water in the boiler enters cavity 1 from the inlet and heats the boiling head. after exchanging heat, the temperature of the hot water decreases, and the density of the cooled hot water increases and has a larger gravity, so it flows downward and flows back to the boiler from the backwater outlet. Hot water circulates naturally in the pipeline system composed of boiler and cooking head, which is called thermosyphon effect. Use the heat of the boiler to hedge the cooking head for heating and heat preservation, which is one of the major functions of E61.

E61 another function praised by the world is the automatic prepreg function. The hot water pressure of making espresso is equivalent to 8: 10 atmospheric pressure, and if the water under such high pressure is applied to the surface of the coffee cake at once, it is not very beneficial for coffee extraction, so engineers who design and make coffee machines should try to avoid it. On E61, an expansion cavity (cavity 4) is designed to slow down the pressure establishment process. In addition, hot water from the boiler through the inlet to cavity 1, cavity 2, cavity 3 and then to the water distribution network, it has to go through tortuous and narrow pipes, which play a good role in limiting current. Therefore, for the E61 head, the hot water pressure is slowly established, and this pressure establishment process is called preleaching.

Next, let's take isomac as an example to look at the working process of E61's head.

In the picture above, the small handle of the isomac coffee machine is in the closed position. At this time, the intake valve is closed, hot water cannot enter cavity 3 from cavity 2, and the cam pushes the prepreg valve ejector rod and unloads. The pressure valve ejector is pressed, and the prepreg valve and pressure relief valve are open.

To make coffee, move the handle up to the horizontal position, the microswitch behind the handle is pressed (see picture below), and the pump starts. At this point, both the prepreg valve and the pressure relief valve are closed, while the intake valve is open (cam against the intake valve ejector, see section of E61 cooking head). When hot water is injected into the open pipes and cavities of the cooking head, the pressure rises. When the pressure exceeds 1.5 atmosphere, the prepreg valve (expansion valve) opens and hot water enters cavity 4. As a result, before the hot water is filled with 4, the coffee cake is pre-soaked at 1.5 atmospheric pressure. Once cavity 4 is filled, the hot water pressure begins to rise again until the required 8-10 atmospheric pressure is required.

After the coffee production is completed, the handlers are moved to the vertical position, the fretting switch is closed, the water pump is stopped, and the cam releases the intake valve ejector rod and the pressure relief valve ejector rod, and the pressure relief valve is opened. the pressurized hot water in the cavity between the brewing filter bowl and the water distribution network, cavity 3 and cavity 4 is discharged from the pressure relief outlet to the coffee machine drain tank.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

WBC game machine internal structure sharing NUOVA SIMONELLI

NUOVA SIMONELLI:WBC game machine internal structure sharing!

- Next

Bodum Columbia‧ French filter kettle & #8231;French Press

Bodum Columbia French filter kettle French Press French filter kettle, also known as French pressure. This method of brewing coffee, according to Wikipedia, was invented by the French in 1850. Because of its simple use, it has been popular for more than a hundred years and has many users. The principle is simple: put the ground coffee powder into the pot and pour it into hot water at the right temperature.

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?