Processing of green coffee beans: processing coffee fruits (solarization method)

It is true that the variety of coffee determines the natural flavor, but the treatment of raw beans can determine the acquired quality. Selected coffee pays most attention to flavor and quality, so it pays special attention to the technology and details of call processing. After harvest, the fruit must immediately enter the treatment process, otherwise it will begin to ferment, making coffee beans have a bad smell. There are two treatment methods: "San-Dry" and "Washing". These two methods will cause different flavors. Sun-dried beans have a complete natural mellow flavor (Full Body), gentle aroma (Mild Aroma) and more gum; the washing law has a good mellow taste, high aroma and lively sour taste. Mellow taste is an important condition of espresso, which will produce a mellow and smooth feeling as strong as wine. Espresso lovers can increase the weight of sun-dried beans; water-washed beans are as clean as clear wind chimes and are suitable for follicular coffee brewing because of less miscellaneous smell. In addition, washed beans have a good sour taste, which is the source of sweetness in espresso.

The sun drying method is also called "natural drying method" (Nature Dry) because it uses natural sunlight to dry the fruits and raw beans of coffee. Due to the use of artificial and natural treatment methods in the process, the sun-cured beans look irregular and unflattering in appearance. However, its mellow taste and consistency are preferred by some experts. The steps of solarization are as follows:

1) Bean selection: put the harvested fruit in the water tank, and the ripe fruit will sink, while the immature and overripe fruit will float up and can be removed.

2) drying: let the selected ripe fruit be exposed to the sun on the square for 5 or 6 days until it is fully dry. At this time, the fruit turns dark brown and the moisture content drops to 13%.

3) shelling; after drying, the peel becomes fragile and easy to fall off, so it can be removed by machine. Farms run by enterprises usually have their own shelling factories, while small farms are processed by processing centers.

4) selection and grading: exquisite farms identify defective beans manually or by machine, pick them out and throw them away. Manual selection usually uses conveyor belts about meters wide, and several female workers sitting on both sides pick out bad beans visually; on some good farms, they are even selected several times until defective beans are not seen. The machine selection rule uses computer identification to eliminate defective beans. Then there is the grading process, in which coffee beans are divided into several quality grades according to established standards, with good coffee entering the selected coffee market and bad coffee entering the commercial coffee market.

5) polishing: the exocarp and endocarp can only be removed by shelling. At this time, the silver film is still wrapped in the outer layer of the seed, and the film must be ground by machine. Then, pack the coffee beans into a bag of 60 kilograms, which can be sold at a price. The weight of bags varies slightly from region to region, most of which are packed in sacks of 60 kg, while Jamaican Blue Mountain Coffee is packed in wooden barrels, with both 30 kg and 70 kg.

Source: network

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

What is the secret treatment of coffee beans? Fundamentals of Coffee introduction

Coffee has become the darling of the beverage industry because of its strong flavor, round taste and mellow taste. People's busy work is inseparable from the refreshing effect of coffee, and people's leisurely life is inseparable from the pleasant embellishment of coffee. The love of coffee drives people to study coffee constantly. In order to show the flavor of coffee more incisively and vividly, the more kinds of coffee are produced after processing.

- Next

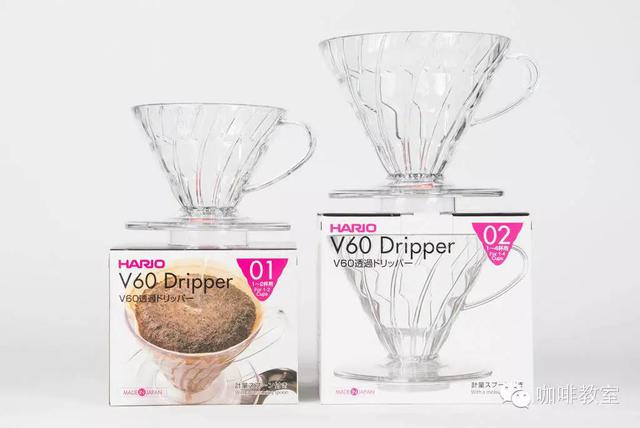

Hand-brewed Coffee: guide to Hario V60 trickling Cup extraction

The key to making a perfect cup of coffee is extraction, and the V60 drip filter cup can explain this perfection. What makes it stand out among many coffee utensils? With regard to the Hario V60 trickle filter cup, its inventors combined chemistry, glassware and coffee. In fact, if you have read the article "Chemex Coffee Pot extraction Guide" (try to give it to you in the next issue)

Related

- What is the meaning of lactic acid fermentation with coffee bean treatment?

- How to judge the state of foam by sound?

- How does the latte pull out the unicorn pattern? Come to get for a little trick to improve the flower pull!

- Will flower pulling affect the taste of the latte?

- Do you know the history of coffee?

- The difference between honey treatment and sun washing what is raisin honey treatment?

- What kind of milk can a novice use to make coffee foam to keep the foam longer? The correct method and skills of milking tutorial sharing

- Why do washed coffee beans taste sour? Flavor characteristics of washed Coffee

- Introduction to the skill of how to practice the size and height of water injection around the circle of hand-brewed coffee

- How do beginners practice coffee flower drawing from scratch?