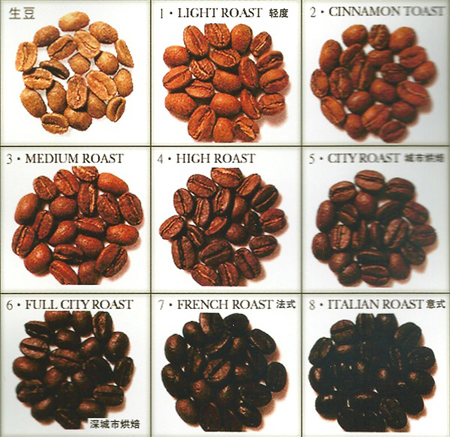

Chemical changes of coffee beans during roasting and color evolution of coffee beans

What happens when coffee beans are roasted?

In fact, no one can answer this question very accurately. One of the mysterious characteristics of coffee beans is that their aromatic compounds are very complex. at present, it is known that there are about 700mur850 substances related to flavor in roasted coffee beans. the actual number of substances varies depending on the subject of each experiment and the species of the sample beans, so we can only speculate on the number of substances. It may also have something to do with the geographical conditions of the producing area and the treatment methods of drying and later stage.

Of course, this figure does not include other ingredients that have nothing to do with flavor. About 2000 ingredients have been identified in raw coffee beans of the Arabica species (Coffea Arabica).

This daunting amount of substance makes coffee the most "complex" thing in daily food and drink. The number of flavor compounds like wine is not as large as that of coffee beans, while vanilla has only about 150 flavor composition positions (this data is provided by professional chemists). Vanilla is also one of the most complex natural condiments. To this day, some "coffee-flavored" food and beverage condiments are extracted directly from roasted beans, rather than by artificial chemical synthesis. This is also due to the "high complexity" characteristics of coffee bean components that are difficult to replicate.

But one thing we can be sure of is that the 700mur850 flavor components in Arabica coffee beans will not show any "fragrance" if they are not "baked". Therefore, "baking" is a necessary action to awaken the spirit of coffee raw bean flavor, and this action has undoubtedly become the most difficult step for coffee learners to control. Wang Sen Coffee West Point School is the only school in the country that teaches coffee bean baking technology. let you always enjoy the special taste of the taste buds.

Rough denial says that baking has the following purposes:

1. Take the excess water out of the coffee beans.

two。 The coffee beans are dried and the xylem is expanded, so that the coffee beans can have more vents and the total weight of the coffee beans is reduced by 14% and 20%.

3. Start a continuous process of converting sugar into carbon dioxide gas, which does not stop immediately after baking and continues until the coffee beans are stale.

4. Take away some volatile substances, and a small portion of caffeine will also be taken away.

5. Some of the sugars in coffee beans are converted into caramel, and some of the ingredients are converted into substances that we become "flavor oils". Flavor oils are very small units and easily destroyed, but the ingredients that make up this compound do not look so delicious, such as aldehydes (Aldehydes), ketones (Ketones), lipids (Esters), Acetic Acid (acetic acid), Butyric Acid (butyric acid), (Caleric Acid) and so on.

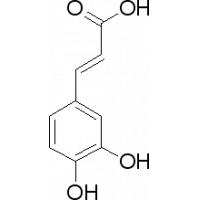

Coffee is actually made up of caramelized sugar, combined with flavor oils and other components (such as bitter factor Trigonelline, quinic acid and nicotinic acid, etc.), plus about 1% caffeine, a drink that is so complex and mysterious that drinkers all over the world are so happy to drink.

Some of the ingredients of roasted coffee beans are converted into protective caramelized sugar and flavor oils, which are hidden in the loose pores of xylem (if in more deeply roasted coffee beans, some of the flavor oils will be forced to be brought to the surface of the coffee beans, making the appearance of the deep-roasted coffee beans always look oily and bright) Carbon dioxide is also emitted from the inside of the coffee beans, a process called "Degassing", which helps protect flavor oils from oxidation (of course, when carbon dioxide emissions stop, flavor oils are quickly oxidized and stale). Vacuum cans, nitrogen-filled bags and so on are artificial preservation containers to protect coffee bean flavor oil from oxidation. When the natural protective measures of coffee beans fail because of grinding, the carbon dioxide gas will dissipate more quickly!

The dramatic evolution of the various stages of baking

What I just mentioned is something that happens inside the coffee beans, so what will happen in the appearance?

A few minutes before the coffee beans are heated in the baking room, we don't see much change in appearance, when the coffee beans are still grayish green and there is no sound. After a while, the coffee beans gradually turn yellow and smell like sacks, followed by steam that smells like toast or shells.

Finally, between the second and 15th minutes of the start of baking (the length of time will be related to the amount of baked beans and the strength of baking firepower), the neat smell becomes heavier and more like coffee, and the "First Crackle/crack/Popping" sound of coffee beans will be heard in a moment!

This phenomenon, which we call the "first explosion", means that the internal composition of the coffee bean really begins to change, that is, the "pyrolysis" begins, when the sugar inside the coffee bean begins to "Caramelize", and the water originally locked in the coffee bean begins to evaporate along with the carbon dioxide gas, also because of this process. Will cause "the first explosion" this small internal drastic change. At this stage, the static water in the coffee beans turns into gradually greasy baking smoke, which continues to thicken.

After the stage of the first explosion, according to accurate measurements, the energy generated by the zigzag shape of the coffee bean is 350 degrees Fahrenheit / 175 degrees Celsius from the starting point of the first explosion pyrolysis, about 435 degrees Fahrenheit / 225 degrees Celsius for roasting to moderate roasting (Medium Roast), and about 475 degrees Fahrenheit / 245 degrees Celsius for very deep roasting (Very Dark Roast).

The deeper the roasting of coffee beans, the deeper the coloring. The main reason for this phenomenon is caramelization and the thermal transformation of some acidic substances. Roasting can be stopped at any point after the pyrolysis begins: at first, the appearance of the coffee bean is very light brown; at the end of the roasting, the appearance of the coffee bean becomes very dark brown, so deep that it is close to black. For people with a more sensitive sense of smell, the smell of baking smoke also changes slightly as the baking pattern deepens.

When the appearance of the coffee bean is close to medium brown, the relatively blurred sound of the first burst gradually fades until there is no burst at all. After that, the coffee beans are further heated to a deeper roasting mode, and the second violent burst begins, called the "second burst" (Second Crackle). It is speculated that the cause of the second explosion is that more volatile substances rush out quickly, resulting in the rupture of the xylem structure of coffee beans; when the second explosion becomes denser and denser, the baking smoke becomes thicker and thicker, and the appearance of coffee beans is darker and smells more pungent. Beans are bigger!

There are three ways to determine the degree of baking:

1. It is judged by the change in the smell of "baking smoke": this is a method of baking depth control that was more widely adopted in the 19th century.

two。 Judged by the "temperature change" inside the coffee bean: this method is most commonly used in today's more advanced bean dryers.

3. By the coffee bean "appearance coloring degree" to judge: this needs to rely on empirical judgment, or rely on a sophisticated machine to assist judgment.

Judging the baking depth visually is probably the most approachable way right now, and it's also the easiest way for people who bake coffee bags at home. On the other hand, large-scale commercial bean dryers tend to use the way to detect internal temperature changes in coffee beans, and gradually, there are more and more small-scale cafes, due to the use of professional bean dryers. Compared with these two methods, judging the evolution of the baking stage by the change of smell has become a forgotten skill, and only a handful of bakers have adopted this method, which requires professional training. Most small cafes in the early 20th century trained roasters in this way.

The same batch of coffee beans (that is, coffee beans with the same harvest time and post-processing period) are roasted by two different roasters, qualified to roast coffee beans to a similar degree of coloring or baking depth, and the taste may be roughly similar; in other words, the flavor change of coffee beans is mainly attributed to roasting. That's why the flavors of the two handfuls of coffee beans at the same baking depth are so similar, rather than the two completely different flavors. However, if different baking utensils, different baking methods and different baking concepts are used, it is a different matter.

Some roasters tend to bake coffee beans slowly at lower temperatures, others tend to bake coffee beans quickly at higher temperatures, and some roasters increase the baking temperature several times according to different baking stages. after the moisture in the coffee bean is removed more fully, the temperature is increased to turn on the pyrolysis. Thanks to a variety of baking methods and roasting utensils, the world of boutique coffee has flourished in so many ways.

Source: Wang Sen International Coffee and Western Food College

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Is coffee acidic or alkaline? What if the coffee turns sour? What does the sour coffee mean?

Boss, why is the breakfast coffee sour today? I don't like it. Can you give me a cup of coffee that is not sour? Many people have this experience when drinking coffee in a cafe. Most people mistakenly think that coffee is sour if it is not fresh, and sour coffee is not good. This is really a great smear and misunderstanding! In fact, coffee itself is an acidic drink. Whether coffee is sour or not depends on beans.

- Next

Analysis of the steps in coffee roasting the roasting degree of coffee and the roaster of coffee all affect the quality of beans.

Once the coffee seed is planted, no one can change its final quality. However, the color, aroma, bioactive components and health characteristics of coffee are related to the roasting process. During the roasting process, coffee is heated at 190-220 degrees for 7-20 minutes, which helps to bake out its aroma and good taste, and helps to form lactone, nicotinic acid and resistance.

Related

- What is the meaning of lactic acid fermentation with coffee bean treatment?

- How to judge the state of foam by sound?

- How does the latte pull out the unicorn pattern? Come to get for a little trick to improve the flower pull!

- Will flower pulling affect the taste of the latte?

- Do you know the history of coffee?

- The difference between honey treatment and sun washing what is raisin honey treatment?

- What kind of milk can a novice use to make coffee foam to keep the foam longer? The correct method and skills of milking tutorial sharing

- Why do washed coffee beans taste sour? Flavor characteristics of washed Coffee

- Introduction to the skill of how to practice the size and height of water injection around the circle of hand-brewed coffee

- How do beginners practice coffee flower drawing from scratch?