Why do Sumatran coffee beans use wet planing? traditional semi-washing brings classic Mantenin flavor.

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

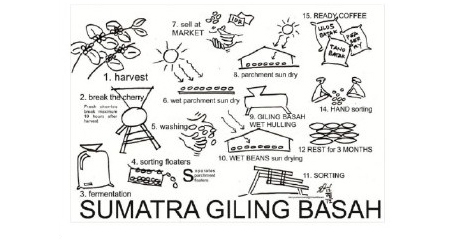

The editor has introduced the Sumatran semi-washing method, that is, the wet stripping method, because of the treatment process, it often produces many different flavors, such as wood, soil, mildew, spice, etc., these flavors may not be very pleasing to most people, but knowing this, why is Sumatra still treated in this way?

First of all, because of the climate of Sumatra and the high humidity here, it is necessary to adopt the method of short drying time. In fact, the bigger reason is that most of the raw beans in this producing area are purchased from different small farmers. That is to say, the small farmers in the middle turn coffee cherries into shelled raw beans and sell them to buyers on the first floor. The purchasers will then resell these raw beans to distributors, who will turn them into dried raw coffee beans and then sell them to traders. Why does such a trading process lead to the birth of wet stripping? Mainly because the small farmers want to cash out soon.

(the processing and market entry process of traditional Sumatran coffee beans)

At present, there is no independent processing plant in Sumatra to buy coffee cherries directly, so small farmers have no choice but to use their own buckets as traditional washing fermentation tanks, and then immediately throw the coffee beans into the fruit shell machine (but because the raw beans are still soft, they will be squeezed by the machine, so they will show a sheepfoot shape). Remove the pulp and shell of the beans, and the moisture is about 30anth40%, or higher. This is very different from traditional washing or tanning, because it is usually not treated until the moisture level is only about 13%. If you wait for the real drying before giving it to the acquirer, the time to realize cash will be lengthened (because the sun usually takes 27 Murray 30 days). Therefore, it is only after going to the traders that the sun or machine drying is carried out to reduce the moisture of raw beans to 13%. After that, the beans are screened and hand-selected, and the beans are sold in different grades according to the defect rate and the size of the beans, and the beans are kept clean for 90 days. so that the beans can have a good "rest and recuperation", so that the moisture of the beans can be consistent (this is called the activity balance of water).

The whole process is handled by different people at different stages, and the condition and quality are very difficult to control. In addition, the washing and fermentation of small farmers, in fact, there is no real fermentation, but only to wash and buoyancy to remove too bad beans, and does not have the role of traditional washing fermentation tank, so the flavor is more impetuous, the strain is difficult to control, and the taste is not so clean. In terms of sun exposure, unlike the traditional sun-drying method, the pulp is used as the basis for fermentation, which can produce fruity coffee beans. Therefore, Sumatra wet stripping method, in the global competition of high-quality beans, the flavor can only be "special" to compete, the long-term development is not very optimistic.

Manning is doing well in the global market only in countries that traditionally like Manning, such as Japan and Taiwan. But now more and more boutique beans, with their unique floral, clean or fruit flavor, are gradually beginning to replace the love of Mantenin in these countries. This special treatment brings a special flavor, but it brings limitations to the development.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Late-night coffee only belongs to the common boutique Mantenin distinction and brewing parameters.

For the exchange of professional baristas, please pay attention to the coffee workshop (Wechat official account cafe_style) Blue Lake Mantenin, Lindong District, Indonesia. Parameters: Diamond filter cup / Pegasus scale 4 / powder ratio 1: 15 / water temperature 94 degrees C / steaming 30s/ total time 2m20s late night coffee only belongs to Mantenin, tobacco, bitter charcoal burning taste, earthy taste and long-lasting throat rhyme, give people the impression of Mantenin with smoke

- Next

Classic Asian mantenin flavor, unforgettable mantenin unique taste

For the exchange of professional baristas, please pay attention to the coffee workshop (Wechat official account cafe_style). Arabica coffee was introduced into Indonesia as early as the Dutch rule in the 18th century. Mantenin is called the most important coffee in the world. It is the fourth largest producing country in the world with an annual output of 7 million bags, of which Arabica accounts for only 10-15%. The main producing areas are located in Sumatra and Java.

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?