Look at the baking curve-how to determine the temperature point, a burst point?

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style)

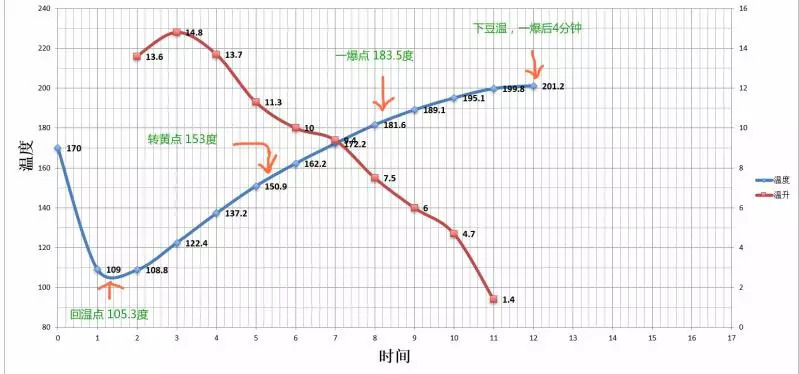

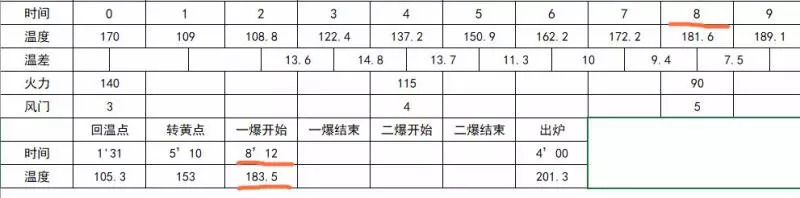

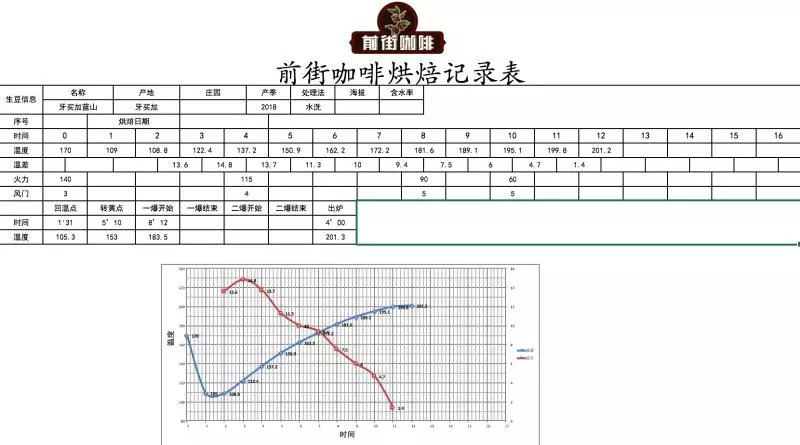

Every time we bake a bean, we record the baking curve, the temperature of the bean, firepower, temperature, explosion time and so on. Why record it? It is hoped that according to the last numerical reference, we can copy the flavor of the same coffee and maintain the consistency of the taste. The key data are coffee bean temperature curve, air, ambient temperature curve and heating rate curve, which can deepen the understanding of beans by measuring coffee bean color change, air flow and gas pressure.

In the process of designing the baking curve, a bean should be baked "thoroughly" from the inside to the outside, and on the basis of baking, a better baking technique should be used to judge at which baking stage a good flavor can be shown. How to create more possibilities for this stage? How to make a tradeoff between controlling flavor and defective flavor? How to ensure the balance of the ups and downs of this coffee bean, and how long will it develop with what kind of firepower after an explosion?

As the usual production requires me to choose a baking capacity of 550g (full load) into beans to share my experience:

Called beans

▼

What are the key points to pay attention to during the baking process?

The temperature of lower bean mainly affects the degree of caramelization and pyrolysis of sugar (mainly sucrose) in coffee. Caramel reaction and pyrolysis reaction need to absorb heat to complete, so these two reactions need to provide heat all the time, so in coffee roasting, the degree of these two reactions is proportional to the lower bean temperature, the higher the lower bean temperature, the deeper the reaction.

Before entering the beans, the temperature of the boiler will be kept at a stable value. The temperature of the boiler is the temperature detected by the temperature probe in the baking chamber. As far as the drum roaster is concerned, its position is usually in the relative position on the other side of the bean temperature probe and will not come into contact with the beans. Part of the bean baking machine does not have a furnace temperature probe, and takes the temperature of the exhaust probe of the roaster as the furnace temperature.

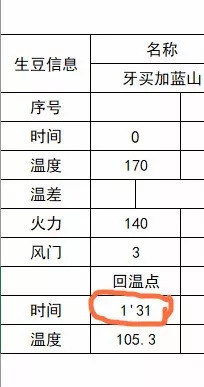

Bean temperature: 170 degrees

Roasting is the source of coffee flavor, roasting raw beans is called roasting, raw beans can not be drunk without baking, roasted coffee beans have determined 80% of the taste of coffee, the roasting process is very tricky, the fire is too strong, the fire is too weak, then the inner ripe overcooked. Coffee beans are roasted internally and externally, and the key point is to control the heat.

[firepower]

The firepower directly affects the roasting degree of coffee beans. The flavor of the coffee beans and the time we want to bake. The more firepower, the more flavor, but at the same time. All flavors are not necessarily good flavors. With enough firepower, coffee beans can release more flavor substances. But it also highlights the bad flavor of coffee beans.

[temperature recovery point]

Beans into the boiler, will immediately absorb heat, the boiler temperature will suddenly drop, and then reach a certain point in time, the temperature rises, this equilibrium point is the return point.

[turning yellow point]

Raw beans enter the endothermic stage, in order to transfer heat to the inside of the beans, use the conductivity of water, if the water content of beans is low, the time to reach the yellowing point will be shorter, on the contrary, if the beans have more water content, the time to reach the yellowing point will be longer. Water evaporation is converted to steam, and the internal vapor pressure and temperature of the beans rise, when the beans begin to expand, destroying chlorophyll and entering the yellowing point.

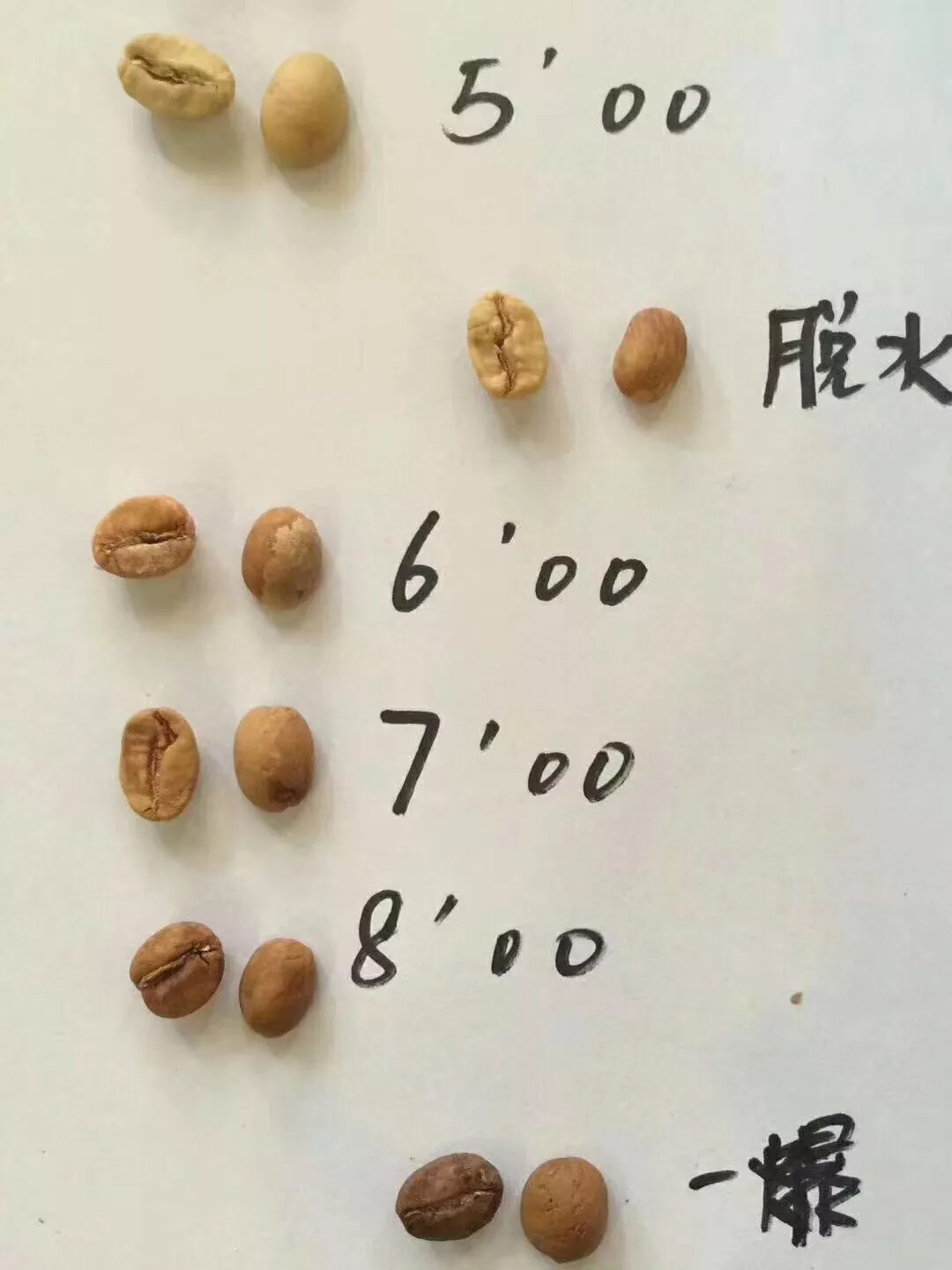

We also sampled some beans from the baking process to see how this has changed.

So throughout the baking process, we should cooperate with the use of the throttle, adjust the flavor of coffee beans to the best state, and ensure the cleanliness of coffee beans at the same time.

Through proper caramelization, coffee will have a higher complexity and level, thicker taste, bringing caramel, chocolate, barbecue and other flavors to the coffee. Pyrolysis can break down the substances that bring plant flavor to coffee.

[burst point]

An explosion refers to the obvious and strong sound of coffee beans in the machine during coffee roasting, a bit like the sound of making popcorn or burning firewood. When the coffee bean absorbs heat and the pressure caused by the evaporation of water in the bean is greater than the strength of the coffee bean itself, the cell wall of the coffee bean will burst because it cannot withstand the pressure of the heart expansion, and the coffee bean will make a burst sound and release heat and sound energy.

This is the emergence of "one explosion". Release different flavor compounds (that is, aromas of flowers, fruit, etc.) and browning (that's why coffee beans are brown). At this time, it is also a time when the development of coffee beans has changed greatly, it may only come out one second earlier or one second later, and its flavor can also be very different.

[temperature rise]

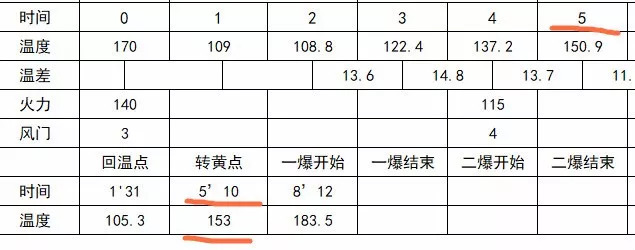

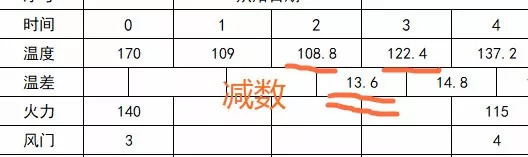

The temperature difference between the two time points, as shown in the figure, there will be a temperature difference between the second minute and the third minute. Subtract the latter (122.4 °C) from the former (108.8 °C) to get a value (108.8 °C).

Take baking [Jamaica Blue Mountain] as an example, it is necessary to understand the nature of this bean. Blue Mountain is a NO.1 bean with more than 17 mesh, with a defect rate of less than 3%, a moisture content of about 13%, and a medium bean density, which is suitable for baking with steady improvement.

In the process of designing the baking curve, personal experience, in the baking process, it should be noted that the blue mountain baking curve is suitable for low bean temperature, the bean density is small, the temperature rise is not too high after an explosion, the temperature rise below 6 degrees will be better, lengthen the development time.

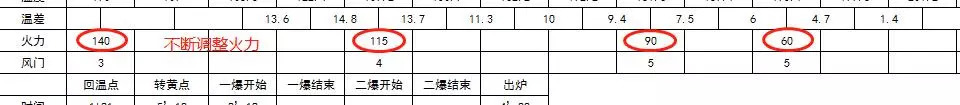

First of all, the furnace temperature is 170 degrees Celsius, the fire power is 140 degrees after the throttle is set for 1 minute, the throttle is unchanged, the temperature is 153 degrees, the bean surface turns yellow, the smell of grass completely disappears, the dehydration is completed, the firepower is adjusted to 115 degrees, and the throttle is changed to 4.

In the 8th & # 39th minute, ugly wrinkles and black markings appear on the bean surface, and the smell of toast obviously changes to the smell of coffee, which can be defined as a prelude to explosion. at this time, listen clearly to the sound of an explosion point, and start to explode at 8 degrees 39 ". Adjust the firepower to 90 degrees, the throttle is fully open (adjust the firepower to be very careful, not to be so small as to be free of bursting sound), and put the pot at 201.3 degrees.

This baking gives a perfect and delicate balance of acidity, mellow thickness and aroma, with bright and delicate acidity, velvety texture and slightly penetrating aromas with hints of flowers, spices and caramel. there is a hint of cocoa on the palate.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

What are the common types of defective beans in raw coffee? the effect of defective beans on coffee

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) according to the statistics of the International Coffee Organization (ICO), there are about 1.5 million metric tons of defective beans worldwide in a year. Defective beans will be consumed by the producing countries or transferred to low-cost formula beans, made into comprehensive coffee beans or sold cheaply to instant coffee factories to make three-in-one coffee and so on. Mixed bitter taste

- Next

Indonesia PWN Gold Mantenin Coffee Bean Flavor and taste characteristics description of Mantenin hand Coffee parameters

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) if you prefer mellow and full-bodied taste, [Manning] series of beans is also a good choice, [Golden Manning], [Tiger Manning] can choose, then why Manning chose deep

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?