How does the coffee roaster work? What are the types of coffee roasters? Direct fire, semi-direct fire, heat

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style)

How does the coffee roaster work? What are the types of coffee roasters? What's the difference between direct fire, semi-direct fire and hot air?

One pot, two beans, three baking. " In this sentence, the factors that affect roasting coffee are pointed out.

Pot refers to the machine used to bake coffee. The stability and controllability of the bean baking machine are related to the replicability of flavor. In other words, the occasional high-quality baking is not worth rejoicing, the good taste must be able to be copied again, maintain a certain level. Therefore, machine manufacturers have made great efforts in this respect. in addition to the increasingly accurate temperature measurement, thanks to the development of science and technology, the new bean dryers in recent years have even been able to adjust the throttle and firepower according to the data set by the computer. trying to minimize the error caused by human operation

Under the condition that the roaster is stable and controllable, the result can be predicted from the quality of raw beans, and what is put into the machine is what comes out. The water content and texture of raw beans will be affected in the baking process. Fresh raw beans have rich aroma and flavor after being baked at high temperature. if they are stored for too long or in an improper environment, the flavor of raw beans will be lost, and the final result must be far from satisfactory.

Baking skills are put last because the difference between the same raw beans when using the same machine and baking in the right way is the so-called personal baking style. The biggest difference is usually caused by the depth of roasting, which makes the coffee different in acidity, sweetness, bitterness and richness, and the retained flavor and cleanliness are also key.

Understand the design principle of coffee roasting machine

Take the bean baking machine made in Taiwan as an example, during the baking process, the functions that can be controlled are gas firepower, exhaust valve, and boiler speed, while the temperature observation values provided are the bean temperature in the furnace and the temperature of the air outlet. There are bean viewing windows and sampling rods to judge the appearance and smell of raw beans.

The rotating boiler is to let the raw beans be heated evenly, and the good baffle design in the boiler makes it more lively and leaping when stirring, so as to avoid point scald. When the rotational speed is slow, the raw bean is in contact with the boiler for a long time; when the rotation is fast, the raw bean is thrown in the hot air for a long time, both of which will affect the flavor. However, the speed of the boiler cannot be adjusted on the baking machines in Germany, Japan and the United States.

In addition to firepower, the distance between the gas fire row and the boiler, called fire distance, is also a difficult problem in machine design. The modification of the Japanese brand bean dryer is to increase the number of gas nozzles, but the problem of uniform heating is also considered when the fire is farther away. The new machine made in Taiwan changes the design of gas nozzles to three rows and double switches, igniting according to the amount of baking, and increasing the flexibility of operation.

Ignition heating, heat energy through conduction, convection, radiation of these three types of coffee beans have a heating effect.

In addition to the full hot air machine is mainly convective heat, we often hear of semi-hot air and direct fire type of these two machines. To put it simply, the wall of the baking room of the direct-fire bean dryer is perforated to allow the radiant heat to act directly on the raw beans. Such a machine can also be equipped with a far-infrared kit to maximize the effectiveness of the radiant heat.

The semi-hot air machine mainly uses conduction heat and convection heat. When the firepower is fixed, the size control of the exhaust valve is the main factor affecting the convection heat.

We must first understand that raw beans are hard seeds in coffee berries. In addition to crude fiber, they also contain water, chlorogenic acid, protein, alkaloids, caffeine, fats, sugars and other substances. At the same time of baking at high temperature, the above substances will appear chemical changes such as Mena reaction and Stryker degradation, resulting in coffee tannic acid, tobacco acid, aromatic esters, alcohols, carbohydrates and other substances that affect the flavor of coffee.

So, when it comes to roasting coffee beans, we can think of it as a process of rising temperature, but it must be under control. Because of this, the temperature and heating rate during baking are the main reasons for the difference in flavor.

From the actual baking process, we can observe the change in the color of raw beans, from the turquoise when the water content is high, to a whitish yellow after baking at high temperature to remove most of the moisture. As the temperature continues to rise, it gradually yellowes, and when it reaches the temperature at which the Mena reaction occurs, the surface turns brown and deepens gradually. If you continue to heat up, there will be carbonization, coffee beans will become dark black, the surface is still bright with grease, if you do not stop heating, it will eventually catch fire.

In addition to the change in color, the volume of coffee beans will also change. In addition to a small degree of thermal expansion, there will be two bursts at different temperatures, increasing the volume by as much as 60%. As the volume expands, the total weight will also be reduced due to the loss of moisture and the removal of silver skin, and the weight will be reduced by about 12% as the baking is shallow to deep.

In addition to the baking temperature and time, we can preliminarily judge the roasting degree of coffee beans by the appearance color, volume change and weight loss ratio. In addition, it can also be detected by Agtron caramelization spectrum analyzer to accurately get the depth of baking degree.

Coffee roasting will face a variety of problems, only familiar with the principle of coffee roasting, continue to accumulate experience, coupled with improvisation, baristas can master superb skills.

To do a good job in baking, every production link can not be ignored, the selection of materials should be fastidious, the weighing of materials should be accurate, and the operation should be careful. Baking is a science. To understand the principle of baking, we must first understand the three ways of heat conduction, convection and radiation.

Conduction refers to when the heat is transmitted by the heat source, causing the surrounding molecules to vibrate and release heat, gradually moving from the high temperature to the low temperature. The conduction of stainless steel has the phenomenon of uneven heating, which can easily lead to colder and hotter parts of the pot.

Convection means that when the material is heated, the fluid material or gas rises due to the volume expansion and the decrease of density due to the heating action, and its position is supplemented by the colder and denser fluid exchange around it, and then rises by heating, and the surrounding material is added. Such a continuous cycle of heating motion is called convection.

Radiation does not need any medium, and the heat can be radiated directly to the object to heat it. The most common form of radiation used in food is the use of dielectrics, microwaves or infrared rays. In the specific operation of baking, it is often baked in two or three ways at the same time, depending on the environmental conditions at that time.

The problems commonly encountered in coffee roasting are as follows:

First, when the preheating temperature of the baking room is insufficient, the coffee beans are immediately put into the oven, which prolongs the baking time. Therefore, the baking loss is large, and the color of coffee beans is light, which is due to the lack of heat and the lack of full coking of the skin, resulting in a lack of color and rough internal tissue.

Second, the temperature of the oven in the baking room is too high, and the hard crust is formed prematurely on the surface of the coffee, which suppresses the expansion of the internal tissue, and because of its fast surface coloring, the operator mistakenly thinks that the product has been baked and ends the baking ahead of time. The inside of this kind of bean is sticky and dense, it doesn't expand as it should, and it doesn't have a normal flavor.

Third, the gap is too long after preheating. The internal furnace that has been empty for too long accumulates too much heat, and as soon as the coffee beans enter the oven, all the heat sources will concentrate on the surface of the beans at the initial stage of the baking process, forming too strong heat, then the heat disappears and cools rapidly, and the unstable temperature in the furnace causes uneven heating inside and outside the coffee beans.

Fourth, the baking time is too much or not enough. The baking temperature and time should be adjusted according to the number of beans. A small number of baking rooms have more space, and the metal conducts more heat radiation, so the temperature is lower, while when the number is larger, the temperature can be higher. The baking time also needs to be adjusted flexibly. The heating of beans in the oven is nothing more than the absorption of heat from the appearance and surrounding to the center of the beans, so the baking can be observed from the changes in the appearance of the beans.

Fifth, did not develop a good habit of recording, baking by feeling, resulting in insufficient stability, can not form their own sufficient baking curve database, as a reference for future baking.

In addition, the type and performance of the roaster will also cause the difference of baking time and temperature. From the direct fire type or gas type up and down fire mode in the past to the electric heating type commonly used now, the convection design of energy has been continuously improved. At the same time, the installation of fans can improve the stability of thermal convection, make the color of baked beans more uniform, and save electricity and baking time.

Advanced tools and equipment make the baking process easier to operate, and it is equally important for operators to accumulate baking experience.

In short, coffee roasting will face a variety of problems, only familiar with the principle of coffee roasting, continue to accumulate experience, coupled with improvisation, baristas can master superb skills.

Roasting of coffee

Through the burning of the fire, release the aroma of coffee, release the sour, sweet and bitter taste of ─ contained in each bean incisively and vividly, from the insipid raw bean to the endless aftertaste of mellow ─ roasting, is the most important stop to outline the character and nurture fragrance in the long journey of every coffee bean.

Whether in a professional roaster, on your own fire or in an oven, coffee beans last about 12-16 minutes and the temperature is as high as 240 degrees Celsius, but in the process of this hot conversation, coffee beans have to go through many chemical changes to make a second popcorn-like crisp sound and lose 10% of the water of 20% of the color.

Baking process, like popcorn full of fragrance and joyful bouncing sound. From raw beans, light roasting to deep roasting, the water is released again and again, the weight is reduced, but the volume slowly expands and bulges, the color of coffee beans deepens, the fragrant oil is gradually released, and the texture becomes crisp. Raw beans ─ each coffee cherry contains two raw beans, and the fragrance is still deep in it, waiting to be discovered. Raw beans contain a lot of chloric acid, which disappears with the baking process, releasing familiar and pleasant fruit acids such as acetic acid, citric acid, and malic acid found in wine. Baking is just right to present these beautiful sour tastes in moderation, while if you bake them too much, they will be completely masked. When baked for 5-7 minutes, the beans begin to release water, changing from light green to orange, emitting the unique aroma of creamy roasted vegetables.

Light baked ─ when the beans make the first light sound, the volume expands at the same time, and the color changes to a delicious cinnamon color, so it is also called CINNAMON RAOST or HALF-CITY ROAST. Acidity dominates the flavor of shallow roasted beans, texture and taste have not been brought into full play, so they are generally used as canned coffee, can not meet the real coffee experts.

Medium roasted coffee beans are elegantly brown. New Yorkers like to start each day by roasting coffee beans with fragrant milk and sugar at breakfast, so this method of baking is also called BREAKFAST ROAST or CITY ROAST. Medium roasting can not only preserve the original flavor of coffee beans, but also moderately release aroma, so Blue Mountains, Colombia, Brazil … Wait for a single cup of coffee, choose this kind of baking method. When roasting deeper, the oil begins to surface, and the beans are burned to a bright dark brown, called FULL-CITY ROAST. Some people think that the sour, sweet and bitter taste of coffee reaches the perfect balance, and the character of coffee beans is clearly carved out.

The darker the color of deep-roasted ─ coffee beans, the sweeter the flavor, when the oil has been turned into caramel, bitter, endless aftertaste, the most suitable for brewing strong ESPRESSO coffee, so it is also called Italian roasting. Moderate roasting gives life to the coffee beans and turns into an intriguing sour, sweet, bitter and astringent taste. However, people who are sensitive to caffeine might as well choose deep-roasted beans as much as possible, because caffeine will slowly escape during baking, so the deeper the roasted beans, the lower the caffeine content.

Note: the sour and bitter taste of roasting degree will still vary from coffee to coffee, and the main drinking method varies from person to person.

Various heat sources ◆

◇ tube burner

The gas burner used in our FUJIROYAL1 roaster.

Bend the iron pipe and drill 72 holes of 2.3 inch with an electric drill.

This process is a very practical process.

It is usually the job of a new member in our club.

◇ Bunsen burner

Our FUJIROYAL3 "5" 10 "and some large roasters are used.

A gas burner with a distinctive name, a burner with a burner invented by Mr. Bunsen in Germany.

The burner used in our company has about the gas consumption of 1000KCAL.

Both the semi-hot air type and the direct-fire type are used, but the direct-fire roaster must be cleaned regularly because coffee shavings fall on the stove mouth.

◇ air gun burner

In our large roaster lineup, the burners used in roasters over 30 years old are used in completely hot air roasters.

The back end of the roaster is equipped with a hot air generator to generate hot air to bake coffee beans.

◇ charcoal fire

Soft coffee is baked with the soft heat held by charcoal (the temperature of Vivas is low) and the far infrared and infrared rays produced by charcoal fire.

Because coffee will have the fragrance of charcoal fire,

Will bake unique coffee.

◇ infrared

Infrared generating device installed on the side of the inner pot

Bake coffee from the heat source of the gas burner below and the radiation heat source from the side.

A roaster with very little demand.

The heat source corresponding to high-quality coffee,

I hope to get everyone's attention in the future.

◆ inner pot characteristic ◆

FUJIROYAL coffee roaster currently has 4 kinds of inner pots!

The taste of coffee does not matter, and the use of coffee roasters is also different.

◇ direct-fired inner pan

The inner pot has been punched,

The burner flame at the bottom comes into direct contact with the coffee beans.

The direct-fire flavor is attached to the coffee.

Into fragrant and delicious coffee.

The flame and heat of the burner are the main heat sources of baking.

◇ semi-hot air inner pot

The inner pot is made of iron plate.

The rear part of the inner pot is punched,

Hot air is introduced as a result.

It is important to control the firepower of the burner below and use the exhaust valve to regulate the convection of the air in the pot.

◇ semi-hot air double-layer inner pot

The outer side of the iron plate of the semi-hot air pot is then wound with a layer of iron plate,

An inner pot in which an air layer is formed between the iron plate and the iron plate.

Raw beans do not come into contact with iron plates that are heated by the flame heat source of the burner below.

It is the inner pot that has attracted much attention and been consulted by many parties recently!

◇ far infrared surface coating inner pot

Apply far-infrared surface coating to the inside of the direct-fired inner pan.

The roasted Zhongyuan infrared ray shines directly on the coffee beans.

The tar covered with coffee on the inner pot can also be exposed to far infrared light.

With a strong radiation source, it can easily penetrate into the interior of the coffee.

Exhaust ◆ of ◆ roaster

An indispensable exhaust system for coffee roasting.

It is also the most nerve-racking part from the beginning of using the roaster.

What is the function of ◇ exhaust? ◇

■ exhaust smoke.

When coffee is roasted, it produces a lot of smoke.

If the coffee in the baking is too exposed to the smoke

It will give the coffee a strong smell of smoke.

Open the exhaust valve while baking,

Let's vent the smoke efficiently.

■ removes the silver skin from the coffee beans.

The silver skin attached to the raw bean will fall off as the roasted coffee bean expands.

These silver skins will have a bad effect on the taste of coffee, so they should be removed carefully.

■ controls the thermal convection of the gas burner.

Coffee roasting is mainly 'the balance of temperature change and time'!

If the coffee beans are paid with a strong and large amount of heat source, the baking will be completed in a short time.

However, it is often difficult to bake coffee beans with a weak and small amount of heat.

According to this relationship, it can be controlled at will.

Coffee beans range from coffee beans as soft as Brazil or Blue Mountains to hard coffee beans like Guatemalan beans at higher altitudes.

And coffee beans with very small particles like mocha.

It is very important to transfer heat to the center of the coffee bean.

But not too much heat transfer.

It all depends on how the heat source is paid!

The thermal energy is controlled by the burner and the exhaust valve.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

How to drink deep-baked coffee powder? How to brew deep-roasted coffee beans? Is there any way to cook it?

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) how to drink deep-roasted coffee powder? How to brew deep-roasted coffee beans? What kind of cooking method do you have? The roasting degree of coffee has many names, such as French roasting (French Roast), Italian roasting (Italian Roast) and urban roasting (City).

- Next

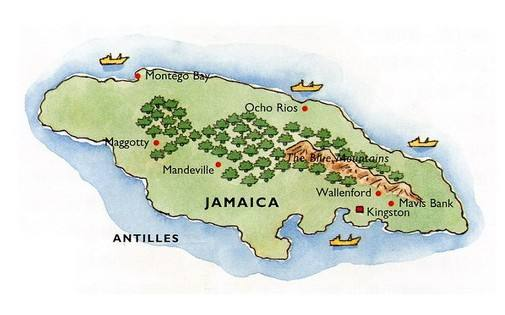

Authentic Blue Mountain Coffee Bean Price authentic Jamaica Blue Mountain Coffee how much is a jin of Blue Mountain Coffee Brand Price list

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) the real output of blue mountain coffee beans is really only a little bit a year, less than 1% of the global demand, authentic blue mountain coffee beans are fixed buyers long before they bloom, or super

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?