Louise Manor in Brazil how to make good coffee in the sun with all red fruits and how to make Brazilian coffee beans

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style)

Because of the large scale of coffee plantation in Brazil, the time history of refined treatment is usually divided into sections.

Divide the planting areas and plant plural varieties.

The Bourbon used by LCF in Chima Farm is grown by a research institute in State.

And was selected to be suitable for the Siladot area of the quality products.

The ripening of coffee fruit is not formed together, but from the upper part of the tree to the lower part.

So wait for the lower part to mature before harvesting. As a result, the fruit of the upper part of the coffee appears as the fruit of dried raisins on the tree.

And the lower part is usually harvested after ripening. The upper fruit is insolated and the lower fruit is washed.

Environmental characteristics: the rainy and dry seasons in Minas Sirado are very obvious, and it will not rain during the harvest period.

As a result, Brazilian coffee fruit will not be affected by rain when it is dried on the tree after ripening, and there is little risk of falling or smelly medicine and smelly fermentation.

Qianjie cooking parameters are suggested:

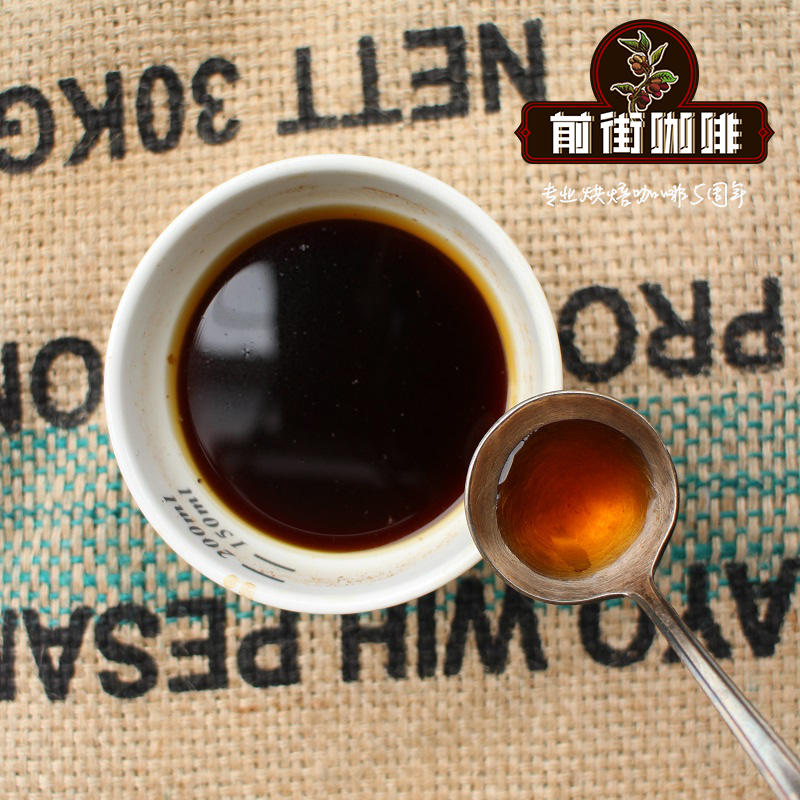

How to make Brazilian coffee [Louise Manor all red fruit in the sun]?

Qianjie Coffee hand reference: weigh 15g [Louise Manor all red fruit sun] coffee powder, pour into the grinder for medium grinding, the finished particles are slightly thicker than salt, we use BG bean grinder to scale 6A (standard sieve pass rate 50%), water temperature 88 degrees, kono/kalita filter cup extraction, recommended powder ratio around 1:14.

The hot water in the hand flushing pot draws a circle clockwise with the center of the filter cup. Start the time when brewing, brew the coffee to 30g in 15 seconds, then stop the water injection, and when the time is up to 1 minute, the second water injection. The second water injection is the same as before, draw a circle clockwise with the center of the filter cup, and the water flow should not rush to the place where the coffee powder is connected with the filter paper, so as not to produce channel effect.

Coffee powder to the outermost circle to set aside a circle, and then another circle to the middle, 2 minutes 10 seconds, to the coffee to 210g, brewing coffee is finished.

| Japanese ice hand flushing [Louise Manor full red fruit sun]

Qianjie coffee ice hand [Louise Manor all red fruit sun] reference:

Brazilian coffee [Louise Manor all red fruit sun], medium and deep roasted, BG bean grinder scale 5R (standard sieve pass rate 60%)

20 grams of powder, 150 grams of ice, 150 grams of hot water. The water temperature is 88 ℃ higher than the recommended normal hand flush, then 1 ℃ higher, the normal grinding small Fuji 3.5 scale, the ice hand flushing is slightly smaller than half a grid-small Fuji 3 scale, the recommended powder (water + ice) ratio is 1:15.

The amount of steaming water is 40 grams and the steaming time is 30 seconds.

Water injection by stages, 60 grams of water in the first section and 40 grams of water in the second section. Use a thin but high water injection column and stir hard to make the coffee powder fully tumble, but be careful that the water level is not too high and do not rush to the edge of the filter paper.

The whole extraction time is about two and a half minutes (close to the normal extraction time of 20 grams of powder).

END

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Brazil sun yellow bourbon DB Wugui manor do hand brewed coffee how to grind beans_hand brewed coffee how to grind

Professional coffee knowledge exchange More coffee bean information Please pay attention to coffee workshop (Weixin Official Accounts cafe_style) Brazilian yellow bourbon coffee, Cerrado region of Brazil in South America, rare yellow bourbon coffee, each bag is accompanied with identification, indicating the name of the manor, the name of the owner and the barcode, which can be traced

- Next

How about Brazilian Giselle Coffee? how about Diamond Chocolate Coffee? is it good?

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) Giselle Brazilian Diamond Chocolate Origin: Santo Antonio Variety: yellow Catucai treatment: Natural non-washing type has won the champion and overall champion in the Brazilian Coe tanning group with high scores sensory description: nuts, yellow sugar, low acid, high sweetness

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?