[advanced knowledge of coffee roasting] basic theory and training contents of professional coffee roasters

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style)

[basic knowledge and training of coffee roasters]

1. Coffee moisture content and Flavor Rule

two。 Selection of Coffee Bean defects

3. Analysis on the characteristics of Bean baking apparatus

Application of 4.ROR

5. Identification of baked bean curve

6. Physical changes and chemical reactions caused by temperature layer and time

7. Caramelization and the influence of taste spectrum

8. An explosion began to enter the key to the decisive victory.

1. Moisture content and flavor rule

The International Coffee Organization regulates the moisture content of the raw coffee bean market to 8 to 12.5% (resolution 407420). Coffee experts have also debated the most appropriate moisture content, but finally concluded that the moisture content of raw beans should be 100.12% ±1%, less than 9% or higher than 13% are unqualified.

#) too much or less than water content

The danger of mildew caused by insufficient dryness!

Excessive dryness will cause the risk of insufficient aroma!

Good moisture content helps coffee produce balanced acidity and excellent aroma, which will improve the cup score. Many bakers like the value of 12%, while the International Trade Center recommends that coffee producers set a target of 11%. Any raw beans of less than 10% may lead to a decline in coffee quality, while a higher moisture content may pose a risk of mold.

The moisture content of raw beans is not directly related to the quality of coffee, and a raw bean with a moisture content of 10% does not necessarily be better or worse than 12%. However, raw beans will gradually lose their activity after a long period of storage, resulting in a stale smell, which is related to the decrease of moisture content of raw beans.

The beginning of the baking process involves accumulating enough heat and pressure in the baking machine to remove moisture from the beans at the beginning of the baking process, which is often referred to by the industry as "dehydration" due to the lack of better terminology. No really important chemical reaction takes place at this stage; on the contrary, when the moisture is expelled, the pressure in the pot begins to increase, creating the conditions needed to bake the coffee. "

If the coffee beans with high moisture content are roasted, more heat is needed during the dehydration period. So the choices are:

1) preheat the outer layer of coffee beans at a higher temperature, but do not scorch them.

2) use higher temperatures during the dehydration phase

3) lengthen the time of dehydration stage.

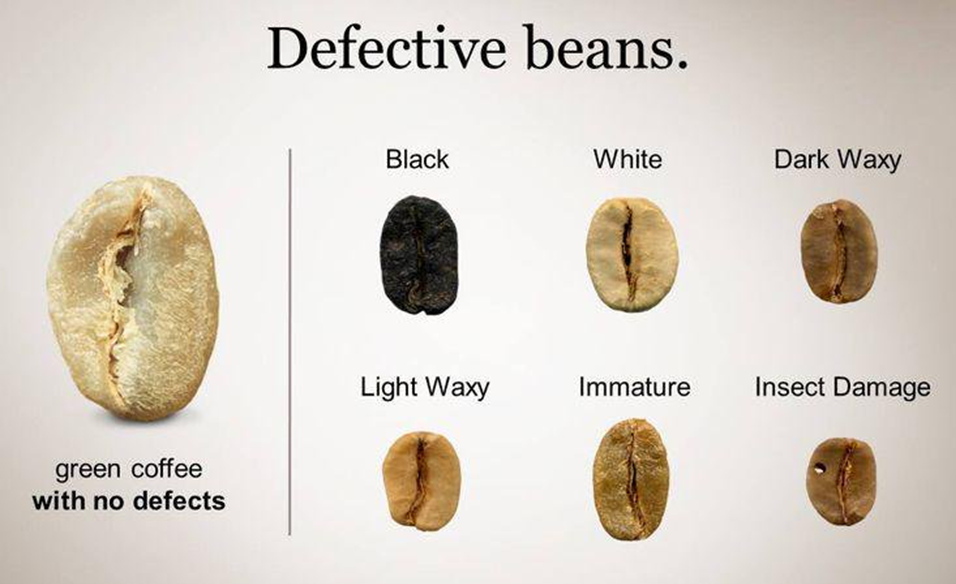

two。 Selection of Coffee Bean defects

Analyze bad coffee, how do you feel after drinking a bad cup of coffee?

First, nausea: raw beans are not fully cooked when baked, accompanied by scorched taste, that is, tricolor beans. (usually caused by the maturity and size of raw beans)

Disgusting: there are so-called defective beans in beans, such as black beans and sour beans.

Third, bad smell: worm-eaten beans or over-fermented beans

Fourth, the health of defective beans: shell beans and broken beans can cause carbonization to cancer, local black beans and worm-eaten beans and fungal infected beans will cause mold infection.

No wonder the American Fine Coffee Association classifies the defects of raw beans and establishes norms and standards.

A, first-level defects: including all black beans, all sour beans (such as honey beans, reddish-brown pectin on the outside can be scraped off, inside is still blue-green, gray-green or yellow-green is not sour beans), dried berries (raw beans are partially or completely covered by exocarp), fungal or fungal infections, foreign bodies, and serious worm-eaten beans (raw beans have more than three signs of worm-eaten and perforated).

B, secondary defects (secondary defects): including local black beans, partial sour beans, shell beans (raw beans are partially or completely covered by sheepskin), floating beans, unripe beans, withered beans, shell beans, broken beans, peels or shells and light worm-eaten beans (raw beans have signs of moth-eaten and perforated, but less than three holes).

3. Analysis of characteristics of bean baking appliance

Besides the basic quality of coffee beans, the equipment and structure of coffee roasting are also decisive factors

A) Heat sources (gas, electricity)

B) Thermal efficiency and heat exchange mode (direct fire, hot air, electric heat pipe)

C) Boiler material (stainless steel, cast iron, ceramic…)

D) Exhaust efficiency (damper)

E) Furnace speed

F) Temperature measurement method

G) Smoke removal system (electrostatic precipitator, water mist, afterburner)

To sum up, each has its own characteristics

Pottery pot art or pottery urn roasting coffee sweetness smooth style unique

Hot air baked beans (hot air direct discharge type) are clean, clear and elegant in flavor

The performance of the electric infrared bean dryer is good aroma, mellow and mild taste

4. Application of ROR

RoR's full name in English is Rate of Rise, which in Chinese is the rate of heating. The term RoR refers primarily to the amount of temperature change per minute, and early baking is primarily calculating how many seconds it takes per degree rise, and then extrapolating back the temperature rise per minute during this phase. RoR is the proper term for recording such processes.

RoR in Chinese is the rate of warming.

Ramp Rate = Rate at which the temperature rises over a "fixed time."

RoR is mostly set at 30 seconds. RoR 6 means that the temperature can climb 6 degrees in 30 seconds.

One problem that is often overlooked in temperature curves is RoR. Just think about the minute warming, and now the prevailing temperature is bean temperature.

The baking process is mainly boiler-type bean baking models, which are ultimately the interaction of contact heat (boiler) and convective heat (hot air).

A stage is from the temperature recovery point to 150℃, and B stage is from 150℃ to the beginning of the explosion. After entering the beans, the beans exchange heat violently with the environment. Usually, changing the damper or firepower at this time will affect the heat absorption of the beans relatively. When the temperature returns, there is a stable initial temperature rise.

5. Identification of baked bean curve

The early traditional roasting method of coffee depends entirely on the experience of the roaster, judging the roasting by the color, taste, smoke and bursting sound of the coffee, and adjusting the heat and valve or other empirical techniques to control the roasting at any time. Then there is the temperature determination baking method or the timing baking method, and then there is the [curve recording baking method], that is, recording the ratio of temperature to time during baking as the basis for baking, which is generally used in commercial semi-hot air roasters. The fire and valve must be adjusted at any time to correct the temperature that must be reached at every time.

Roasting is the process of transforming coffee beans from raw beans to ripe beans rich in aroma and flavor! As long as the process is caused by the comprehensive effect of time and temperature.

1. physical change

two。 Chemical reaction

First of all, let's take a look at the physical changes in coffee beans during roasting.

The importance of physical structure

The layered structure of coffee beans has a great influence on the flavor we want. Without a specific physical structure, the chemical reactions essential to flavor and aroma will not take place.

The most important period of this physical change is the so-called dehydration period before 160 degrees C.

Dramatic changes during baking-color changes, beans get bigger and lighter.

Coffee beans are dense and compact seeds, but once they start roasting, they change their original state. Let's take a look at what happens when roasting:

A change in color

Perhaps the most obvious change during baking is the color. Before baking, fresh raw coffee beans appear blue-green and then turn brown due to melanoid production. These are polymers formed when sugars and amino acids combine under heating. In the baking process, part of the silver skin will also fall off, silver skin is the closest to the coffee bean's outer paper material. Bean bakers and consumers will use color as the quality standard of coffee beans and baking results is the Agtron value.

6. Which is important, physical change or chemical reaction?

Baking is mainly divided into three stages: dehydration, Mena (caramelization) reaction, and flavor development. These terms actually describe the different stages of chemical and physical changes.

A) dehydration

The dehydration process occurs at the temperature recovery point, which is when you put the raw beans in the baking machine, the heat inside the machine will drop before rising again, and the point at which the temperature begins to rise is called the temperature recovery point. During the dehydration stage, the water in the raw beans will begin to evaporate and the pressure will begin to form inside the beans.

B) Mena reaction

When the coffee beans begin to turn brown, the Maynard reaction begins, which happens when heated to about 150 °C. This process produces a lot of gases, including carbon dioxide, water vapor, volatile gases and so on. When the internal pressure is large enough to break through the cell wall, it expands, which is called the first explosion.

Flavor development also occurs at the same time in Mena, which not only changes the color of beans, but also affects the final flavor of coffee.

C) the period of flavor development

When baked to an explosion, baking changes from endothermic reaction to exothermic reaction. At this stage, the physical changes will continue, the pores on the bean surface will continue to increase, the oil will continue to move from the core to the surface, and the color will continue to darken.

Physical change is the change of volume and pores.

The strength of the cell wall of coffee beans ranks at the top of the plant world. they have a tough outer layer that increases their stiffness and strength. When coffee is roasted, the rising temperature and the conversion of water into gas will increase the pressure inside the coffee beans, and these conditions will change the structure of the cell wall from rigid to rubber (also known as vitrification). Because coffee beans contain polysaccharides (binding carbohydrate molecules).

The internal material pushes out toward the cell wall, leaving a gas-filled gap in the center. This means that as the mass decreases, the volume of beans expands, and most of the gas accumulates from carbon dioxide released after baking.

Baking also increases the pores of coffee beans, resulting in lower density and stronger solubility. Of course, it also has a lot to do with turning them into delicious drinks.

Changes in oils and fats

Coffee beans contain oil, and during baking, the internal high pressure causes these compounds to move from the center of the cell to the surface.

Oils help keep volatile compounds in cells. Volatile compounds are chemicals that are highly volatile at room temperature. These substances are essential for producing the aroma and aroma of coffee. Without the oil, these molecules may dissipate quickly.

The longer the baking time, the more obvious the structural change, the lower the density of coffee beans, and the more gas will be produced. And the longer the baking time, the more grease on the surface of the coffee beans.

These developments to some extent explain why the taste of deep-roasted coffee is different from that of light-roasted coffee, but there are also important chemical changes that affect baking results.

Different roasting methods will affect the flavor, aroma and taste of the final coffee, because roasting occurs at different times and temperatures.

Chemical reaction

7. Caramelization and the influence of taste spectrum

The time temperature layer determines the trend of taste spectrum.

a. Shallow baking highlights enzyme action (Enzymatic)

. the flowers are rare and the oranges are wonderful

. onions and garlic are scary and sugarcane is charming

b. Medium baking highlights caramelization and Mena reaction (Maillard Reaction)

. "make caramel sweet.

. "Mena reaction" is better than "caramel"

c. Deep baking highlights dry distillation (Dry Distillation)

. cellulose is the source of all fragrances

. "mercaptan" is the hero of deep roasting incense.

Reaction of chemical components in baking

Sucrose: melting point 187.8 ℃→ sugar complex →; caramelization → water CO2 escape to produce an explosive First Crack phenomenon. Roaster drum bean temperature 190-196 ℃

Cellulose (lignin): coffee cell wall component that breaks down the cell wall at 230℃ and destroys →; second burst Second Crack phenomenon. The temperature of beans in the drum of the baking machine is 211,216 ℃.

Trigonelline (Trigonelline): pure crystal 217.9 ℃ begins to degenerate, when bean temperature 192.2 ℃, when bean temperature 229.4 ℃→ 85% degradation, trigonelline degradation degree (rate) is the key index to determine the best baking reaction ratio.

So after baking, the loss rate of trigonelline (degradation rate) is 50%-80%, which is decomposed into a variety of compounds, including non-volatile nicotinic acid and 29 volatile substances, of which 9 are coffee aromatic substances.

Nicotinic acid: coffee raw bean nicotinic acid often exists in cellulose. Nicotinic acid derives from soluble substances during baking. Nicotinic acid derivatives show good acidity and clean aftertaste (clean finish) in coffee, so nicotinic acid derivative rate is another index to determine the best reaction ratio of roasting.

Ambient temperature (ET): a specific chemical reaction of roasted coffee has a temperature range that produces a good flavor. This temperature range is the ambient temperature.

Therefore, the shallow baking [fermentation catalysis] produces low molecular weight, high volatile sour aroma of flowers and fruits.

Floral flavor is the rarest flavor of boutique coffee, mainly coffee and jasmine fragrance, due to coffee varieties or soil and water relationship, enzymes in the metabolic process, produce a high concentration of floral aldehyde (Floral aldehyde) compounds, resulting in a charming floral flavor.

The fruit taste spectrum of coffee is also the same, mainly citrus and raspberry fruits. The rose summer of Ethiopia and Panama is typical of citrus flavor, especially the rose summer of Panamanian jade manor, which is the king of orange fragrance. This is the contribution of fragrant esters and aromatic aldehydes in coffee.

Light roasted coffee also often has the smell of cinnamon, cardamom and other spices, which is attributed to the volatile compounds of aldehydes, esters, ketones, alcohols and classes, as well as Furaneol, the aroma component of shallow roasted coffee, as well as strawberries and pineapples. Onion, garlic or green onion in a completely cut state, the cell wall is not damaged, there will be no choking smell, once cut, the cell tissue ruptures, the enzyme immediately combines with the original tasteless precursor aroma.

Onion and garlic flavor, which is incorporated into the supplementary flavor spectrum of herbal rhyme in the flavor wheel, and occasionally derives the ingredients of onion and garlic flavor in the process of baking catalysis. In the process of testing dry and wet fragrance, it is often said to smell pizza, seafood sauce, onion and garlic, beef soup. Almost everyone has a different experience.

Durian diluted fruit fermentation flavor or tofu milk flavor, like sweet and a little pungent, is the unique "regional flavor" of the ancient country of coffee. In addition, the blue-green boutique washed beans often send out the comprehensive sweet smell of forage grass and sugarcane, all of which are charming herbal fragrance.

Shallow roasting is most likely to highlight the volatile fruit acid aroma of ester aldehydes and organic acids stored in coffee beans during their development.

Timing enters the baking time to promote the Mena reaction (Maillard reaction), the degradation of coking carbohydrates, nitrogen-containing components and lipids, etc., and the Pyrolysis of sugars, amino acids and Trigonellines to produce unique aroma products with complex components.

The closeness of color and flavor can not be separated, which is properly reflected by Mena reaction and caramelization reaction, maltose is generally / one is the coking of sugar (Caramelization), the amount of sugar is proportional to the depth of baking color, and the other is brown reaction.

So the aromas of nuts, almonds, cream and chocolate come from the Mena reaction rather than caramelization, in other words, if the coffee is caramelized without Mena reaction, it will only be a monotonous bitterness rather than a drink with all kinds of flavors. The nuts in the SCAA flavor wheel are classified as caramelization reactions with many sweet aromas, which seems to simplify the formation of sweetness, and the addition of Mena reaction here can bring the real results closer to the facts. The "odor spectrum" under caramelization and Mena reaction can be classified into three flavors: nut rhyme, caramel rhyme and chocolate rhyme.

(note 1) Caramelization: the carbohydrates or sugars of coffee beans are caramelized at 170C to 205c. Water vapor and carbon dioxide are released after sucrose dehydration. The color of sucrose changes from colorless crystal to brown and produces fragrant substances: "Discatyl" (one of the cream components with the smell of cream sugar); HMF- furans (Furans, with caramel flavor) HAF- maltol (Matol, commonly known as sugar flavor), while caramel accounts for 17% of the weight of ripe beans, bitter taste sweet.

Mena reaction: protein degradation and polymerization. This reaction is not only a chemical reaction, but a series of complex polymerization and degradation of amino acids with reducing sugars such as glucose, fructose, lactose, maltose and so on. This effect does not necessarily occur at a fixed temperature, but for coffee it occurs during the reaction of amino acids with carbohydrates during the process of 185 degrees c and 240 degrees c. Recent studies have found that 10 per cent of the bitterness of coffee comes from the Mena reaction.

If the baking temperature layer is higher, it will enter [Dry Distillation].

A) Deep baking fans fall in love with the incense, smelly, choking aroma and alcohol smell of resin components, which is the product of Mena reaction and distillation. (resin composition: pine and cypress Pinaceae and Taxodiaceae, both secrete olefins with spicy fragrance to protect against pests or squirrels.) "dry distillation" means that solids or organic matter isolate the air and dry until it is completely carbonized. The purpose of air isolation is to prevent oxygen from burning or exploding.

B) the dehydration, pyrolysis, dehydrogenation and coking of re-baked beans before combustion are similar to those of dry distillation, and medium-baked beans will also produce a lot of scorched or pungent odors. Therefore, the deep accompany aroma can be attributed to dry distillation.

C) the shallow and medium baked aromas belong to low and medium molecular weight, but they enter the deep baking world after the second explosion, the carbonization intensifies and the caramelization disappears, but the Mena reaction continues, and the fibers of amino acids and polysaccharides continue to explain and polymerize to produce more high molecular weight adhesive compounds. the right of aroma interpretation from caramel is dominated by Mena reaction and dry distillation reaction, mainly coke and smelly.

8. An explosion began to enter the key to the decisive victory.

Coffee tastes better if it's sweet. To make coffee sweeter, the focus will be on converting bad organic acids while retaining more sweetness, and the key lies in the chemical reaction after an explosion, commonly known as the stage of development (development stage).

During this period, there will be very complex situations, such as:

The Mena reaction continues, and new reactants are formed.

Degradation of chlorogenic acid, citric acid and malic acid

Formation of acetic acid (decomposition of common sugar), quinic acid (decomposition of chlorogenic acid), formic acid and other organic acids

Caramelization of sucrose

High temperature pyrolysis reaction

Put the focus on caramelization, which can simply be thought of as heating sucrose to more than 160 degrees, starting to melt and produce dehydration, darkening the color and volatilizing the aroma of caramel. But the caramelization reaction of coffee is a little more complicated. Caramelization is the dehydration reaction of carbohydrate (not limited to sucrose) after heating. Its reaction products are caramel, acid, aroma substances, carbon dioxide and so on.

The sweet aroma produced by the process of caramelization of coffee includes cream, honey, furan, fruit, etc., while aroma is produced, a large number of stimulating acids such as formic acid and acetic acid are also produced, and carbon dioxide is gasified as caramelization continues, which leads to "second explosion".

Although caramelization begins to occur before the explosion, the main reaction products are after the explosion, whether organic acids or aroma substances. The organic acids will be converted again with the development time, and so will the volatile aroma substances. If the development time is not enough, the acidity will be too strong, robbing the richness of the sweet substances; if the development time is too long, the taste will be passivated and even bitter. In order to give full play to the sweetness of coffee, the time of development and the change of temperature should be properly controlled.

What is the most suitable time for development? Then we suggest that a development time of 20% to 25% of the total baking time is the most appropriate, and the temperature rise curve had better be maintained a smooth decline during this period, without the phenomenon of "crash" or "flick".

In 2014, a book called The Coffee Roaster's Companion Bakery was published, and the author Scott shared his 20 years of experience in a variety of roasters. Scott recommends in the book that [DTR is 2025%] because:

The mainstream roasting degree of boutique coffee is light to medium roasting, and at this roasting degree, DTR 2025% performs well for most light and medium roasted coffee.

Among the baking records of more than 20000 heats of Scott, 20 furnaces with excellent flavor (equivalent to 0.1%) and 18 heats of DTR are between 2025% and 25%.

DTR 2025% is only the conclusion of Scott personal database, and DTR can not be completely used to equate with the degree of flavor development, especially DTR 2025% without crash/flick, many people do not have empirical evidence, as long as baked to 20% is either baked or scorched.

END

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee temperature requires coffee best drinking time temperature American coffee temperature is more or less suitable

Professional coffee knowledge exchange more coffee bean information Please follow the coffee workshop (Wechat official account cafe_style) most coffee drinkers have a preference for drinking temperature, ranging from 70 or 80 degrees hot coffee to near zero degrees iced coffee, as long as you can bear the temperature can drink, that is to say, according to personal preference. But generally speaking, the standard of temperature that we define is at best

- Next

Fine coffee does not take out: from the selection of beans, boiled to tell you what is "fine coffee"

Professional coffee knowledge exchange more coffee bean information Please follow the coffee workshop (Wechat official account cafe_style) after drinking cheap, readily available chain coffee, have you forgotten the feeling of sitting down and enjoying the coffee? Boutique coffee is not only a brand, but also a concept and ideal. And the full cup in your hand must be full of baristas or professionals.

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?