The Central Valley of Costa Rica introduces the history of coffee cultivation in Sonora, a long manor.

Country: Costa Rica

Producing area: central valley

Manor: Sonora Manor

Treatment: insolation

Flavor: black cherry, hazelnut, toffee, berry, nectarine

The Central Valley, or Valle Central in Spain, is a plateau in central Costa Rica. The land in the valley is a relative plain surrounded by several mountains and volcanoes of the Central Mountains. The region has a population of nearly 3/4 of Costa Rica, including the capital and San Jose, the most populous city. The land in the Central Valley is distributed between the provinces of Alajuela, Eredia, San Jose and Catago. The area covers an area of 11366 square kilometers, accounting for 1/5 of the country and is drained by the T á rcoles River. Farms in the Central Valley are relatively convenient, but Costa Rican coffee is famous for growing and processing Arabica coffee with bright acidity and complex fruit flavors.

The history of Sonora

The Manor Sonora Manor (Hacienda Sonora) is a family farm located in the central valley of Costa Rica at the foot of the Poas volcano in Alajuela Carrillo. Diego is the fifth-generation coffee producer in his family. The farm covers an area of about 100 hectares, including 55 hectares of espresso, 35 hectares of wild forest reserves and 10 hectares of sugar cane. The coffee on Mount Sonora, the Great Manor, grows in an environment surrounded by luxuriant trees and other vegetation, providing excellent conditions for high-quality production and improving the chemical properties of the already naturally rich volcanic soil. Due to the diversity of the farm ecosystem, many different species of birds and animals call it a natural habitat.

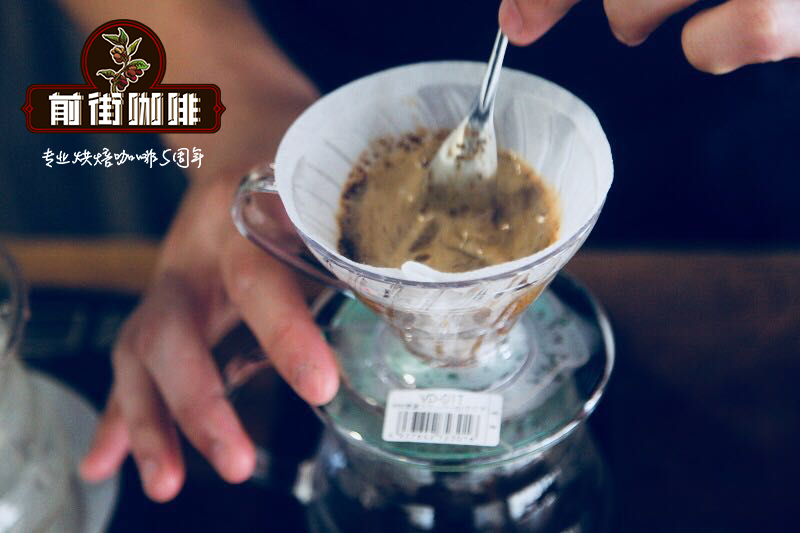

The miniature mill on the farm is located in the heart of Hacienda Sonora, adjacent to a 150-year-old, well-preserved traditional sugar cane press called trapiche. All coffee in Sonora is processed with honey or natural methods, which can gain unique sweetness in the cup and enhance the fruity taste, thus complementing the cup outline formed by different varieties grown on the farm.

Through the operation of generations of farms, proper care of the environment has always been crucial. Using only natural and honey processing methods can reduce water consumption, saving 3 gallons of water per pound of coffee, which could have been used in washing processing. 100% of the electricity consumed by the farm comes from the hotel's renewable energy. Sustainable electricity is obtained from natural freshwater using a special turbine called Pelton Wheel. This energy supplies power to coffee factories and provides some free electricity to workers on the farm.

The Manor Hotel Sonora provides free accommodation for every farm worker and his family, including most family facilities. All employees are entitled to the full benefits of the Costa Rican health insurance system. Producer Diego Guardia and his father Alberto require the Shanora Sonda to have high standards of social and environmental responsibility and to produce high-quality coffee.

Bram is a buyer for Ally in Central America. His office is located near the CECA quality control office and laboratory where he works in Diego, just five minutes from the bike. Sonora organizes the harvest through daytime selection and Bram cups throughout the day to find the ideal profile. Once he has selected batches, these daytime batches will remain traceable for the rest of the processing and shipment preparation.

Sonora carefully records the harvest, which part of the farm they come from and the drying time of each batch. Planning, organization, and annual adjustments are part of the team's standard operating sequence. Their record keeping and communication provide complete logging and processing traceability to record all the details of the journey from the trees to the jute bags sewn for export.

The cherries harvested in this batch will float and rinse with fresh water. The drying process begins on a tarp and then transfers the cherries to a dry drying bed for 14-21 days.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Is Costa Rican Tara Pearl Honey unique in Coffee processing? La Pasra Manor Huang Mi Kaduai flavor

Country of origin: Costa Rica: Tarazu Farm: Finca La Pastora altitude: 1800m varieties: Kaduai treatment: yellow honey flavor: caramel, peach, succulent Tarazu region is located in the high mountains of the South Pacific to the south of San Jose, Costa Rica, is one of the highest planting densities in Central America, with many farms at 2000 m or more above sea level.

- Next

Costa Rica Dago farm verasaki coffee flavor how? Introduction of Dagomi Treatment Technology

Country of Origin: Costa RicaRegion of Origin: Western Valley Farm: Dago Farm Altitude: 1400m Variety: Vera Sacchi Treatment: Honey Treatment Valle Occidental seems to have been created specifically for coffee cultivation, with an altitude of 800-1400 m, humidity always close to 81%, and an average temperature of 21C, all of which contribute to the high production of coffee. West Side

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?