Coffee Technology Fine Coffee Fruit Coffee Bean Processing

There are two ways to prepare coffee beans for the coffee roasting process. The method chosen has a significant impact on the final price and quality of coffee. The cheapest process is called the "dry process" and is used for lower-quality coffee beans, while higher-quality coffee beans are processed by the "wet process."

Drying is used on unwashed coffee beans. Wet processing is used on thoroughly washed or semi-washed coffee beans. Most arabica beans are processed wet, except for drying, which is more common in brazil and ethiopia. In Indonesia, some Robert beans are wet processed, but this is not common locally.

drying method

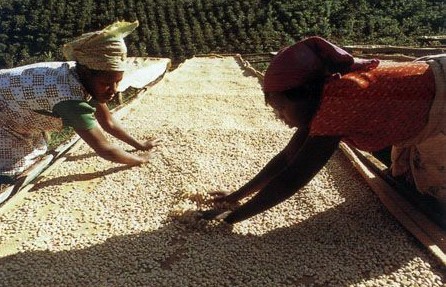

Drying is the cheapest, simplest and most traditional way to process coffee beans. When processing, the harvested fruit should be spread on concrete floor, brick floor or straw mat. Ideally in the sun and raked at regular intervals to prevent fermentation. If it rains or the temperature drops, the fruits must be covered to prevent damage.

After about 4 weeks, the moisture content of each fruit will drop to about 12%, when the fruit is dry. In Brazil, coffee beans at this stage are given a confusing name: cocoa. The skin is dark brown and brittle, and you can hear the coffee beans rattling inside the shell.

The process requires more technology than it seems. Because coffee beans can be overdried, if this happens, they are vulnerable to damage at the next stage, shelling. Conversely, coffee beans that are not sufficiently dried are also vulnerable to damage. The next step is to store the dried fruit in the cellar for a while. During this time, the moisture in the fresh coffee beans continues to evaporate.

wet process

The wet process requires more capital investment and effort, but it helps to maintain the quality of the coffee beans and reduce damage. The main difference between the wet and dry methods is that the pulp is immediately separated from the coffee beans during wet treatment, rather than drying them out as in the dry method.

The pulp is separated in a separating machine in such a way that the fruit is crushed in a machine having a fixed surface and a movable surface or in a machine having movable rods, whereby the pulp is separated from the coffee beans. In order to guarantee the quality of the coffee beans, the separation of the pulp must be carried out as soon as possible after harvest, ideally within 12 hours, but no more than 24 hours. If the coffee beans are left for too long, the pulp becomes difficult to separate from the coffee beans, resulting in incomplete separation and possible damage to the coffee beans.

The peel and pulp separated from the coffee beans will be washed away with water. The rinse tank is designed to have the function of separating light, tender coffee beans from thick, ripe coffee beans. Such separation can also be accomplished by an Aagaard classifier. A coffee grower in Norway, Ogl designed a device to sift coffee beans through filters into a large container of water while growing coffee in Kenya. The large, plump beans sink first, while the lighter beans stay in the larger container. During this process, water can be recycled.

The next step is the most basic fermentation, which uses enzymes to separate the creamy mucilage covering the endocarp. Coffee beans are stored in the fermenter for about 12 to 36 hours, depending on the ambient temperature, the thickness of the slurry, and the enzymes. When this process is complete, the endocarp around the coffee bean is no longer slimy but has a pebbly feel.

Quality control throughout the wet process is critical to prevent coffee beans from spoiling, as even one bean spoils, potentially damaging the entire bean. For this reason, the equipment used must be cleaned daily to ensure that no impurities remain before the next round of processing.

Dried coffee beans

After the wet treatment process, the coffee beans are still preserved within the endocarp shell, which still contains about 15% water. The endocarp must be dried to a moisture content of approximately 11% to ensure that the beans are stored in a stable and safe environment. Moisture content is critical because if arabica beans are overdried to 10% moisture, they lose their turquoise color and their quality degrades.

Coffee beans covered with endocarp should be dried on a concrete floor, slate floor, dry table or plate, similar to drying.

In larger plantations or where rain can disrupt the drying process, mechanical dryers are sometimes used, and coffee beans are placed in air-conditioned boxes where drying wind blows on the surface of the beans. Drying can also be done by sun exposure, turning the beans regularly to ensure complete drying, which takes 12 to 15 days. The most important thing is that the endocarp should not crack, and if the sun is too strong, the beans must be covered.

At this point, the whole process is completed, and the coffee beans become known as "parchment coffee beans"(because the outer pericarp of the coffee beans is quite like parchment, so called). In general, coffee beans remain in this form until the eve of export.

Since coffee beans are exported throughout the year rather than only during the harvest period of about three months, coffee beans are stored in the form of parchment beans under absolutely stable conditions. Heat is the enemy of coffee beans, and humidity up to 70% is also easy to destroy coffee beans, for this reason,"parchment coffee beans" are generally not stored in the farm where they are produced (although in some places there is no choice). Highland-grown coffee beans should be stored at or near the elevation where they are grown, as they are particularly susceptible to moisture. In this environment, Arabica beans should not be stored for more than 12 hours, and Robett beans can be stored for a slightly longer time.

grinding or shelling

Before coffee beans are exported, they are ground, that is, the endocarp is removed from the beans ready for sale. Removing, washing the endocarp, and drying the shell of the coffee bean after the process is also known as shelling or peeling.

It is more difficult to remove the endocarp of coffee beans during wet processing than during drying, so different huskers are needed. There are two main models: friction shell machine and compact shell machine. Engelberg and African models of friction huskers are suitable for dry or wet coffee beans: in a cylindrical box, coffee beans are squeezed between linear ribs and knives, and the shells are scraped by knives to expose the beans.

"Parchment coffee beans" are usually shelled on a Smoot friction huller. Smoot is Belgian, of Scottish descent. He was born in Kneisberg, Prussia, and settled in Guatemala. In 1844, he developed a coffee peeling machine equipped with a rotating body with a screw, which rotates in a box with a screw, and the screw rotates in the opposite direction. As the coffee beans are propelled along the rotor, the endocarp is stripped from the beans. Because the rotor rotates relatively slowly, the rotor generates less heat than other types of huskers.

Other shellers include roll-type shellers (mainly for dried coffee beans grown in South America) and crossbar shellers (equipped with knives).

Outside Brazil, parchment coffee beans are processed in a press sheller rather than a friction sheller. Coffee beans must have a moderate moisture content when shelled, otherwise they may crack. The press sheller consists of a horizontal disk rotating in an annular body, around which the edges are iron needles or irons. When the machine is running, the coffee beans come into contact with the iron needle due to centrifugal force, thus causing the endocarp shell to fall off.

polishing

The silver-colored skin remaining on the beans after shelling must be removed by polishing. Most polishers work on a similar principle to Smoot huskers, except that copper rods are used instead of iron rods because they cause less damage to coffee beans. Copper also gives coffee beans their glamorous turquoise colour. Coffee beans that have been processed with a press huller are usually polished because they always look messier than coffee beans that have been hulled by friction.

Polished coffee beans were historically thought to be superior to unpolished coffee beans, but in fact, when the final brew was tasted in a cup, there was little difference. There are also those who insist that the value of polishing will be affected by the quality of the cup, but it is difficult to find conclusive evidence.

Grading and classification

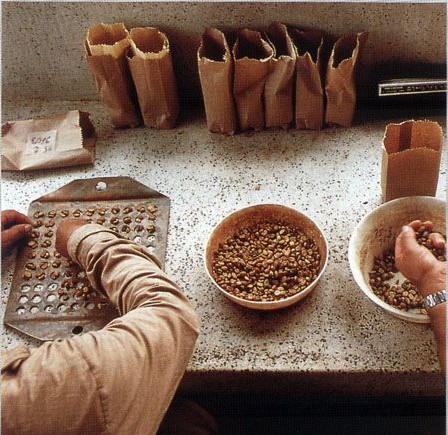

Coffee beans are graded first by size and then by density. With two exceptions, all coffee beans have a fairly regular size and the same proportions. One side is flat and the other is semi-elliptical. The exceptions are the more elliptical pea beans and the larger giant beans (i.e., marago peel beans). The price of these two coffee beans is always higher.

In general, larger coffee beans produce better coffee. The size classification of coffee beans is usually expressed as 10 to 20, but some countries classify coffee beans according to a certain size, such as AA. The way to determine the size of coffee beans is to pass them through a sieve. But even so, there may be weight differences between beans of the same size: and bad, shriveled beans that must be culled will still survive.

The best way to separate unwanted coffee beans from good coffee beans is to use gravity and air. The compressed air method, which is manual and highly technical, uses jets to separate heavy and light coffee beans. Another method, gravimetric separation, is to place coffee beans on elevated plates and let air pass through them to drop heavy coffee beans. This is also a technically demanding method. If used properly, it can separate coffee beans more accurately and effectively.

The next step is to sort the beans. Remove rotting, dark, sour and overfermented or unshelled coffee beans. This process depends on the eye, put the beans on the moving belt inspection.

Other methods include electronic color classification and dichromate methods. Today, however, the best test classifier is still the human eye. But there is no doubt that high-tech microprocessing systems will eventually replace this process entirely.

Coffee beans are graded according to different grading systems in different countries. Some of them, like the classification methods commonly used in Haiti, are too complicated to be effective, while the classification devices used in Brazil, although complex in structure, are indeed necessary. In general, there are six export grades, the highest being SHB(strictly hard bean), or highland coffee beans, grown at altitudes of at least 400 meters.

All coffee beans are evaluated before purchase. It is common practice to buy coffee beans and roast them instead of buying beans that have been roasted at the place of production. The main reason is that coffee beans, once roasted, have a short shelf life. The second reason is that most retailers in America and Europe prefer to buy coffee beans directly from local roasters, so they have better control over the quality of coffee.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

The method of extracting coffee beans from the primary processing of coffee beans by sun treatment

Tanning is a traditional method for the initial processing of coffee beans, and at present, almost all coffee-growing countries such as Ethiopia and Yemen still use solarization to treat raw beans. Sun treatment will first identify sunken beans in the sink, that is, ripe or half-ripe beans are spread in the drying farm for natural drying. The specific time depends on the local climatic conditions, which usually takes two to four weeks.

- Next

The process of turning fresh coffee fruits into raw coffee beans.

The variety of coffee treated with raw beans certainly determines the natural flavor, but the treatment of raw beans determines the acquired quality. Selected coffee attaches great importance to flavor and quality, so it pays special attention to the technology and details of processing. Harvest: the harvest method is one of the criteria for judging selected coffee. if calculated from the time of germination, Arabica coffee will take about 5 years to blossom and bear fruit. Brazil

Related

- What is the meaning of lactic acid fermentation with coffee bean treatment?

- How to judge the state of foam by sound?

- How does the latte pull out the unicorn pattern? Come to get for a little trick to improve the flower pull!

- Will flower pulling affect the taste of the latte?

- Do you know the history of coffee?

- The difference between honey treatment and sun washing what is raisin honey treatment?

- What kind of milk can a novice use to make coffee foam to keep the foam longer? The correct method and skills of milking tutorial sharing

- Why do washed coffee beans taste sour? Flavor characteristics of washed Coffee

- Introduction to the skill of how to practice the size and height of water injection around the circle of hand-brewed coffee

- How do beginners practice coffee flower drawing from scratch?