Processing methods of green coffee beans: analysis of solarization, semi-solarization, washing and honey treatment

Handling of raw coffee beans:

After harvest, the fruit must immediately enter the treatment process, otherwise it will begin to ferment, making coffee beans have a bad smell. There are two methods of treatment: the sun method and the treatment method, which will cause different flavors. Sun-dried beans have a complete natural mellow flavor, gentle aroma and more gum; the washing law has a medium mellow taste, a high aroma and a lively sour taste.

Mellow taste is an important condition in espresso, which will produce a mellow and smooth feeling as strong as wine. Espresso lovers can increase the weight of sun-dried beans; water-washed beans are as clean as clear wind chimes and are suitable for follicular coffee brewing because they have no miscellaneous taste. In addition, washed beans have a good sour taste, which is the source of sweetness in espresso.

Solarization:

The sun drying method is also called [natural drying method] because it uses natural sunlight to dry the fruits and raw beans of coffee. Due to the use of artificial and natural treatment methods in the process, the sun-cured beans look irregular and unflattering in appearance. However, its mellow taste and consistency are preferred by some experts. The steps of solarization are as follows:

1. Choose beans: if you put the harvested fruit in the water tank, the ripe fruit will sink, while the immature and overripe fruit will float up and can be removed.

two。 Drying: place the selected ripe fruits in the square and expose them to the sun for 5 or 6 days until fully dried. At this time, the fruit turns dark brown and the moisture content drops to 13%.

3. Shelling: after drying, the peel becomes fragile and easy to fall off, and can be removed by machine. Farms run by enterprises usually have their own shelling factories, while small farms are processed by processing centers.

4. Selection and grading: exquisite farms identify defective beans manually or by machine, pick them out and throw them away. The manual selection method usually uses a conveyor belt about 1 meter wide. Several female workers sitting on both sides pick out the bad beans visually. On some good farms, they are even selected several times until the defective beans are not seen. The machine selection rule uses computer identification to remove defective beans. Then, there is a grading process in which coffee beans are divided into several quality grades according to established standards, with good coffee entering the selected coffee market and bad coffee flowing into the commercial coffee market.

5. Polishing: the exocarp and endocarp can only be removed by shelling. At this time, the silver film is still wrapped in the outer layer of the seed, and the film has to be ground off by machine. Then, pack the coffee beans into a bag of 60 kilograms, which can be sold at a price. The weight of bags varies slightly from region to region, most of which are packed in sacks of 60 kg, while Jamaican Blue Mountain Coffee is packed in wooden barrels, with both 30 kg and 70 kg.

The quality of tanning is not easy to control, and the main risks are as follows:

1. Unstable climate, rainy or cloudy days

two。 If the fruit is exposed to the sun in the square for 5 to 6 days, sundries will easily infiltrate and be eaten by insects.

3. It must be stirred frequently, but it is uneven, resulting in uneven sun exposure.

Half-sun method:

Because the quality of the solarization method is not easy to control, there is a half-solarization method. Among them, there are several kinds of transformation, the most frequently mentioned are fruit paste solarization and honey treatment. Some people say that honey treatment is Puiped Natural Process, but we do not refute it, because the two methods are too similar. However, according to Los Lajones Manor, honey treatment is a transformation of Puiped Natural Process because it uses little water.

Honey treatment method:

Coffee honey treatment Honey Process introduction: honey treatment is one of the transformation of Pulped Natural Process, in the peeling process of almost no use of water. After farmers use machines to remove the exocarp of coffee, they usually go directly into the sun-drying process without rinsing. Raw beans are laid flat on the shelf, because the pulp and mucus are very sticky, will be attached to each other or on the shelf, farmers must often hold a shovel to stir hard, it is very hard. The whole process will take 10-12 days, and the moisture content of raw beans will be reduced to about 11%.

In Costa Rica, this method is called Miel Process, and Miel means Honey, so some people call it "honey treatment". When it comes to honey treatment, Cruz of Panama is worth mentioning. he is the owner of Los Lajones Manor, who took the lead in experimenting with honey treatment and helped spread it to neighboring countries. In the past, most Central American countries used water washing, and honey-treated coffee beans had relatively high sweetness and melon and fruit aromas, so they could be sold at a good price, and farmers were quite willing to switch to them. Cruz currently runs two estates, Los Lajones and Emporium, whose products are often winners of the best coffee competitions in Panama. Please refer to the company's website.

Honey treatment hardly uses water and avoids wastewater treatment, which is most helpful to the protection of the environment, and the flavor of coffee is very good, so it is worth popularizing. In the work of Mr. Li Songyuan in Pingtung Coffee Garden (coffee cultivation in Taiwan), there is a detailed explanation of honey treatment, which is worthy of reference for coffee growers.

Washing method:

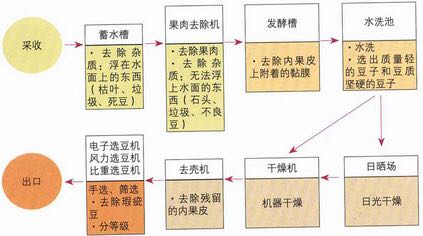

Because there was no sufficient sunshine in the West Indies, the Dutch introduced [WIB], also known as [WIB] (West Indische Bereiding means West Indian treatment), around 1740, and the traditional method of sunbathing was called [OIB] (Oost Indische Bereiding). Coffee beans exported from Java are often marked [WIB], which means washed beans. The treatment steps of the washing method are as follows:

1. Choose beans: put the harvested fruit in a water tank and soak for 24 hours. At this time, the ripe fruit sinks, while the immature and overripe fruit will float up and can be removed.

two。 Remove the pulp: use a machine to remove the skin and pulp, leaving only the coffee beans wrapped in the endocarp. At this time, there is still a layer of mucus on the outside of the beans, and the process of washing is to wash this layer of mucous membrane.

3. Fermentation: mucus has strong adhesion and is not easy to remove. It must be placed in a tank for about 18 to 36 hours to ferment and decompose mucus. There are two methods of fermentation, namely wet fermentation and dry-wet fermentation. As the name implies, the former adds water and the latter does not add water. In the process of fermentation, the seed and the internal pulp will produce special changes, which is one of the steps that most affect the flavor of the washing method. Some farms add hot water or enzymes to speed up fermentation, which has a negative impact on quality and is not popular with selected coffee lovers. Sigri, a famous coffee farm in Papua New Guinea, prides itself on its unique washing method. They have to ferment for three days and wash it with clean water every 24 hours, thus producing a distinctly sweet Sigri Coffee.

4. Washing: farms that use the washing method must build washing ponds and be able to introduce an endless supply of running water. During the treatment, the fermented beans are put into the pool and passed back and forth, using the friction of the beans and the power of running water to wash the coffee beans until smooth and clean.

5. Drying: after washing, at this time, the coffee beans are still wrapped in the pericarp with a moisture content of 50%. It must be dried to reduce the moisture content to 12%, otherwise it will continue to ferment, mildew and rot. The better treatment is to use sunlight to dry, although it takes 1 to 3 weeks, but the flavor is very good and very popular. In addition, machine drying is used in some places, which greatly shortens the processing time and makes the flavor not as good as that of sun-dried coffee. As a result, the selected coffee farms almost always let the sun dry the raw beans.

Selected from the book "selected Coffee"

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Piccolo coffee latte Coffee five Australian specialty coffee culture has spread around the world

With the introduction of Flat White coffee in the United States (Starbucks currently offers small, medium, large and caramel coffee models), Americans are able to taste the delicious coffee invented by Australians. But the contribution of Australians to the world coffee culture goes far beyond that. Today, we are going to count five great inventions about coffee from Australia. Australia

- Next

Introduction to the main points of knowledge of coffee beans: where on earth does the best coffee in the world come from?

The best coffee in the world is produced in Jamaica. Jamaica's Blue Mountain Coffee is known as the King of Coffee. It is produced in the Blue Mountains east of Jamaica in the West Indies of the Caribbean Sea. It is a perfect blend of coffee flavors and has a low yield. Loved by the British royal family. Source: ninety Fan Strange Network

Related

- What is the meaning of lactic acid fermentation with coffee bean treatment?

- How to judge the state of foam by sound?

- How does the latte pull out the unicorn pattern? Come to get for a little trick to improve the flower pull!

- Will flower pulling affect the taste of the latte?

- Do you know the history of coffee?

- The difference between honey treatment and sun washing what is raisin honey treatment?

- What kind of milk can a novice use to make coffee foam to keep the foam longer? The correct method and skills of milking tutorial sharing

- Why do washed coffee beans taste sour? Flavor characteristics of washed Coffee

- Introduction to the skill of how to practice the size and height of water injection around the circle of hand-brewed coffee

- How do beginners practice coffee flower drawing from scratch?