Introduction of coffee bean flavor characteristics of micro-processing plant in Costa Rica coffee bean Tarrazu production area

For professional baristas, please follow the coffee workshop (Wechat official account cafe_style)

Pastora and Canet are two small farms, which in this case are mixed according to the number of days of harvest. Carlos and his entire family are very committed to Don Eli Farm and the miniature mill (micro mill). With the support of his family, Carlos was able to manage both the farm and the milling. He distinguishes his farm according to the number of days of harvest, the block and the process. Local farmers will choose the most mature coffee cherries and then use mechanical degumming before the sun. Process: use an Eco degumming machine to adjust the amount of mucus they want to remove before drying or fermentation. In this case, it would be a "white honey", which means that about 70% of the mucus is mechanically removed and 80% of the mucus is placed directly on the drying bed. Dry: they move the coffee from the bucket to the African bed (African bed) in the greenhouse and place it according to level. Mariajose,Carlos 's daughter and other workers are in charge of the drying process. They flipped the coffee on average every hour and tracked every coffee that came into the greenhouse to dry. Coffee takes about 10-12 days to get the right humidity, which is about 10% Murray 10.5%. This year Carlos uses different heights (levels) so he can dry coffee more slowly and have more space for coffee that needs to be dried.

The Montero family has grown coffee in Costa Rica's wonderful Tarrazu mountains for more than three generations. Located at 1800 meters above sea level, the "La Pastora" mini area (mirco region) is famous for being rich in volcanic soil and providing the best Costa Rican coffee.

Grandfather Eli devoted his whole childhood to growing coffee, and so did his son Carlos Montero. Their enthusiasm for coffee has been deeply rooted in the blood, but what can not be ignored is the plight of the coffee industry. When Carlos saw his father's struggle, he created an opportunity for himself, and finally he succeeded in taking charge of the farm.

Today, Carlos and his entire family are fully involved in Don Eli coffee farms and microprocessors (micro mill). But in the harvest years of 2014 and 2015, Carlos and his entire family faced their biggest challenge today. This is their first year as a boutique coffee producer. But Carlos explains that this is how they adjust their coffee industry, focusing on innovative processing methods and ensuring quality. They reject the concept of mass production and adhere to the core concept of "quality exceeds quality". Carlos realized that he needed to get some coffee certification like NAMA Caf é, and he knew the importance of having good, chemically uncontaminated soil, so he devoted himself to studying the implementation of sustainable practice on his farm. For example, he has a small batch (nano lot) that he has not used chemical methods for many years, and he wants to maintain this batch to do experiments in the future, and name it "Chamaco". Don Eli is committed to growing the best Costa Rican coffee from Costa Rican soil.

The aim is to mitigate and adapt to climate change in the coffee sector, to promote lower green room gas emissions, to reduce damage to the environment in coffee production, to encourage acceptance of new technologies and to enhance production practices, committed to the efficiency of small farms in Costa Rica. The aim is to improve the competitiveness of coffee producers and their families in the coffee industry. "according to this, all countries interested in selling coffee like Europe must have this certification.

Production process

This year Carlos pays more attention to his pickers and the variety of coffee cherries. He ensures that pickers have sorted immature coffee cherries into another basket before he measures cajuelas. Carlos and his son Jacob are a team when processing coffee. After Carlos measures the coffee picked by their pickers, he usually brings coffee cherries to the processing plant in the afternoon, where Jacob waits for coffee to be processed. They moved the coffee cherries from the truck to a pile and put some clean water to wash the coffee cherries so that they could continue to put the coffee cherries into the pulp separator. After that, the beans are moved to the coffee washing machine. At the end of this step, the beans are moved to a large container by water pressure. When the beans are moved to a large container, the coffee's mucus is almost completely removed, but the coffee still has a small amount of mucus, which is why Carlos calls the process white honey.

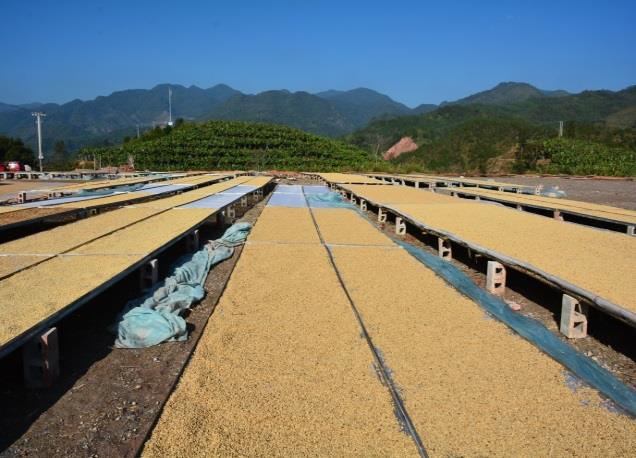

Drying

When the coffee beans are removed from the large container, they move the coffee from the basket to the African bed in the greenhouse. Mariajose,Carlos 's daughter and other staff are in charge of the dry part. They flipped the coffee on average every hour and tracked the drying process of each batch in the greenhouse. The drying process takes about 10-12 days to reach the right humidity (about 10% Mel 10.5%). This year Carlos uses different heights, so he can dry coffee more slowly and have more space to use.

The most fascinating things in Costa Rica are the different classification of batches, different processing processes and preparation methods. You will find that the most typical coffee has adequate washing, different levels of dense treatment, and clean to complex sun drying methods (clean to complex naturals). Even if the price of coffee will be raised as a result, we totally think it is worth it.

We found a very interesting and challenging project in Costa Rica this year (harvest year 2015) and Marianela Montero, a coffee producer, and now we are a buyer of raw beans in Costa Rica. Marianela,22, who grew up on his family's coffee farm, Don Eli, decided to develop and change the coffee industry.

Most of the farms we work with are small (each producer has about five hectares of land), and most of them spend their lives in the coffee industry.

These producers own farms and most of them have their own washing stations (microprocessing plants). Most of the micro-processing plants in Costa Rica are family businesses and are based on family operations. We hope to cooperate with these manufacturers for many years, if / when their mentality and ability are the same and hope to improve year after year. The first thing is to improve the quality of growers, and this partnership is a medium-and long-term plan. We know that we need patience to get the best coffee, and we want to help these producers reach their maximum potential and get a better price through the quality and consistency of each cup. With Marianela joining our team, we believe we can work with producers and "guide" them to get more customized products.

Another key to the success of the project is to be as transparent as possible. We want our consumers and everyone to know how much it really costs to produce a good cup of coffee and how much money can be earned at every step of the production process. Costa Rica is now a high-consumption country, and in order to achieve sustainable development, we believe that reasonable payment is very important, and good prices enable producers to make a living. We need to motivate them to work hard. The advantage is that you have good growth and preparation and can get amazing coffee.

Product name: Don Eli Micromill of Tang Aili processing Plant

Country: Costa Rica Costa Rica

Producing area: Tarazhu Tarrazu

Grade: Screen 15 or above

Treatment method: White honey treatment method White Honey Process

Variety: Kadura Caturra, Kaduai Catuai

Altitude: 1800 m

Flavor: almonds, cream, citrus, outstanding sweetness

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Nicaraguan Coffee Story introduction of Coffee Bean Flavor in Saka River Manor

Coffee is picked by hand. We have a group of experienced people who know how to pick ripe coffee cherries. Each batch is classified according to species and altitude. Separate the floating objects with a siphon. It means that we put the coffee in the tank, so the heavy coffee cherries will sink into the water and the light ones will float. Remove the pulp from the wet mill. We calibrate our machines in order to keep the slime from

- Next

Flavor characteristics of micro-batch coffee beans from Costa Rica, one of the most popular producing areas.

For the exchange of professional baristas, please follow the Coffee Workshop (Wechat official account cafe_style). This micro batch comes from the Gray Wolf Manor (Finca Los Lobos), which has won many outstanding cups in Costa Rican Coffee San Jose Asseri (Aserri), which belongs to the Houkou River processing Plant (Rio Jorco Micromill) and is very focused on product quality and nature conservation. Houkou River

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?