Standardized production technology of Yunnan small-grain coffee, fresh fruit picking and initial processing and washing steps

Fresh Fruit picking and Primary processing of Yunnan small-grain Coffee

The harvest of fresh coffee fruits in Yunnan is generally divided into three periods:

Early ripening fruit from the end of October to the middle of December, with less yield.

The period from mid to late December to the end of January is the concentrated ripening period of coffee fruit, and the overall quality of this batch of coffee is the best.

Most of the remaining fruits in February are diseased fruits, and the yield is very small.

Coffee picking needs to pay attention to:

Coffee fruit is harvested one by one, do not pick the ear, do not pull off the stalk behind the fruit (stalk)

Pick all red fruit, not green fruit or semi-red fruit.

Shade should be taken after fruit harvest to prevent sun exposure.

On the same day, the fresh fruit was harvested and processed within 8 hours. when it could not be processed on the same day, the fruit was poured into the fruit storage tank and soaked in clean water to achieve the role of preservation.

Generally speaking, there are three methods to treat the process from coffee fruit to raw coffee bean: sun exposure, water washing and honey treatment.

The process of sun treatment is to directly expose the whole coffee fruit, and the process: selecting beans, → drying, → shelling, → screening and grading.

More mature beans can be used for the sun (usually 7-12 days), but the risk is greater, it is easy to return to moisture, the sun needs to smooth all the beans and let them dry, and the sun needs to turn every 2 hours. Record the temperature and harvest the beans immediately in case of rain. The moisture content of dried raw beans is reduced to 10%-12%.

It is worth mentioning here that due to the local temperature, microclimate and other factors in the Yunnan producing area, the drying process required for the local solarization treatment takes about a month to achieve the model of solarization treatment, which represents the same dry moisture content of Ethiopia for about 20 days under the same conditions, and during this period, it is also necessary to ensure that there are no uncontrollable microclimatic factors such as rainy weather and humidity.

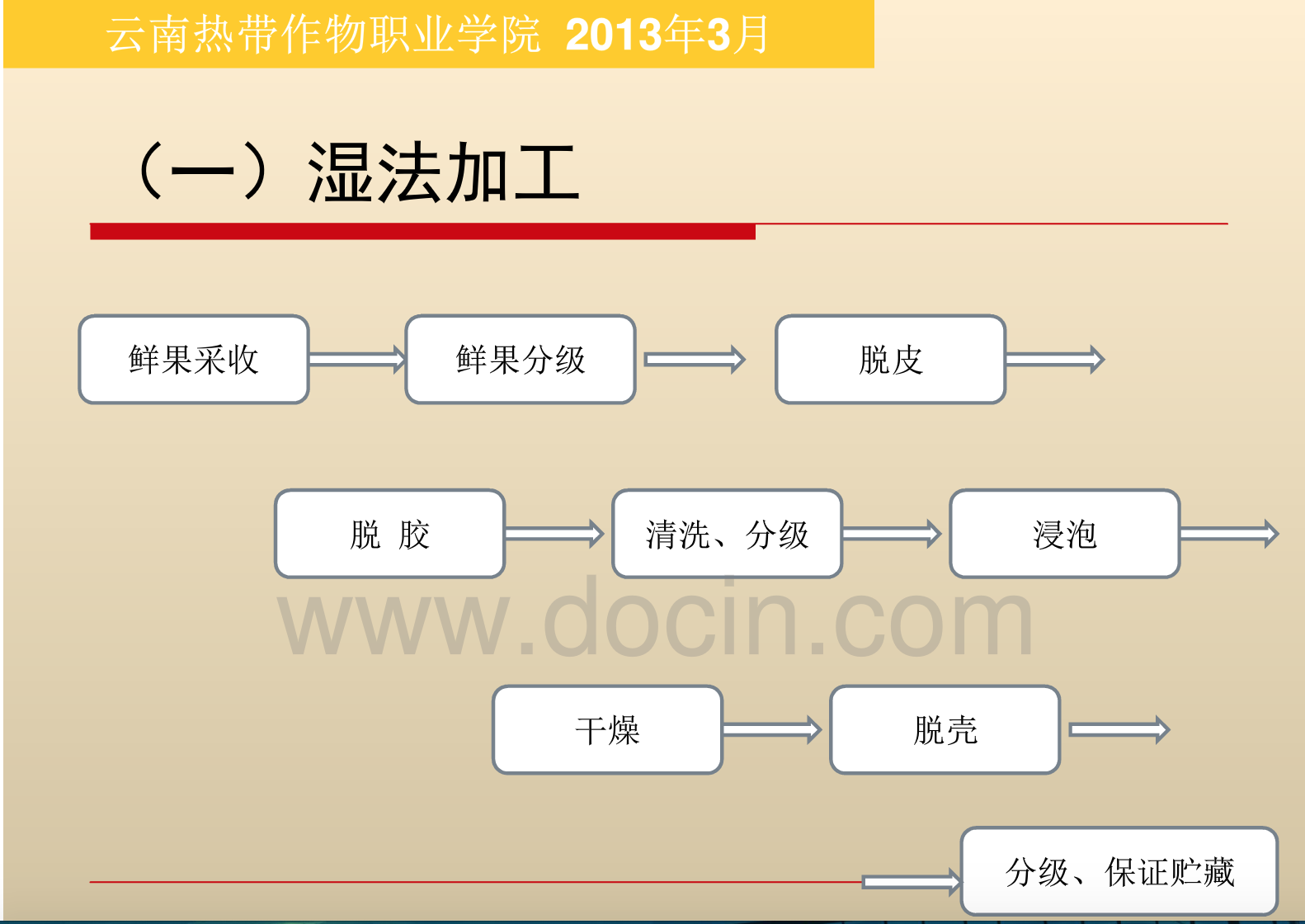

Washing treatment is to remove peel, pulp, pectin, etc., after fermentation in the flume, and then drying; washing process: selecting bean → peeling → tank fermentation → washing bean → drying → peeling → selection and classification.

Peeling machine peeling:

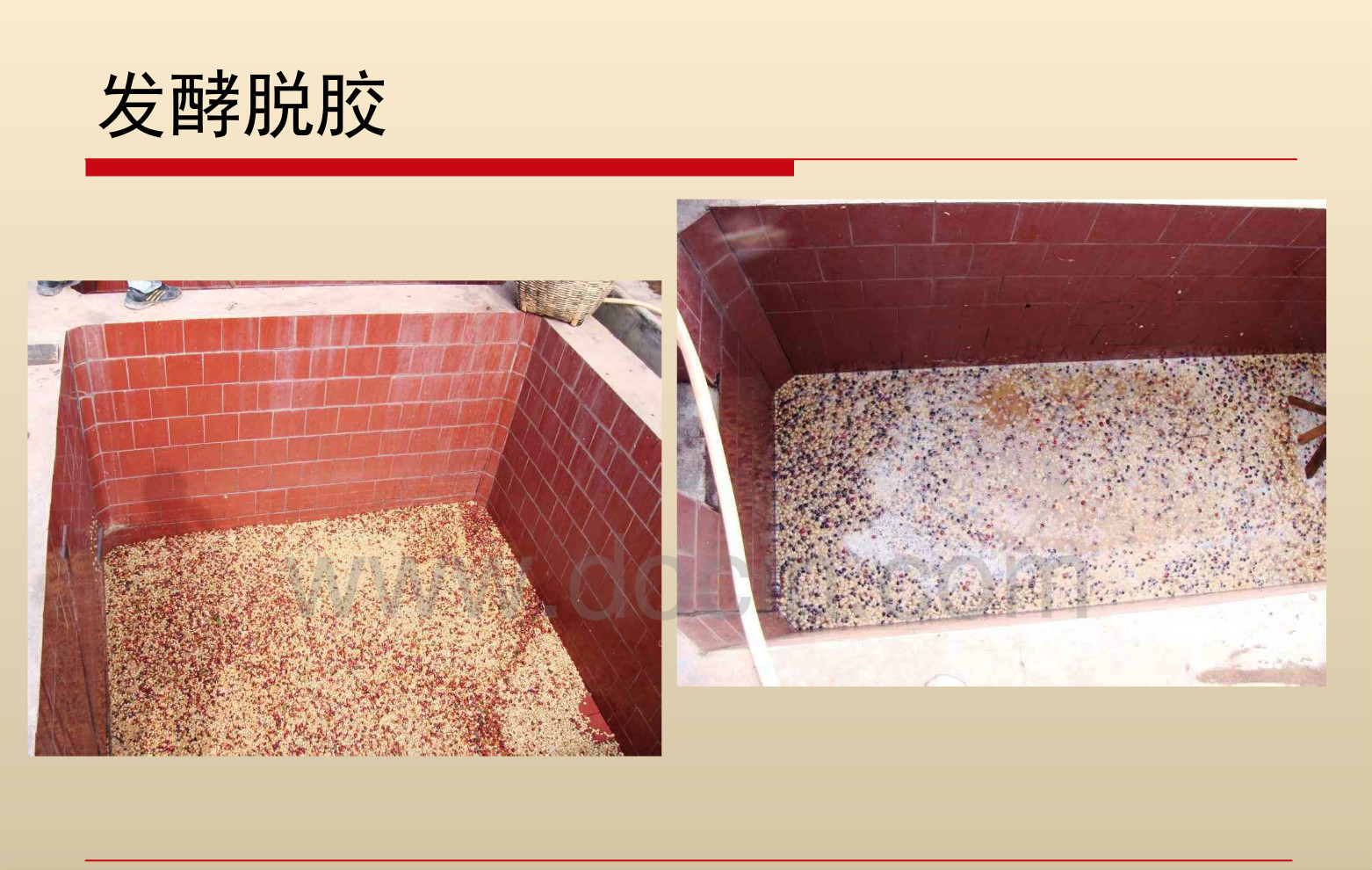

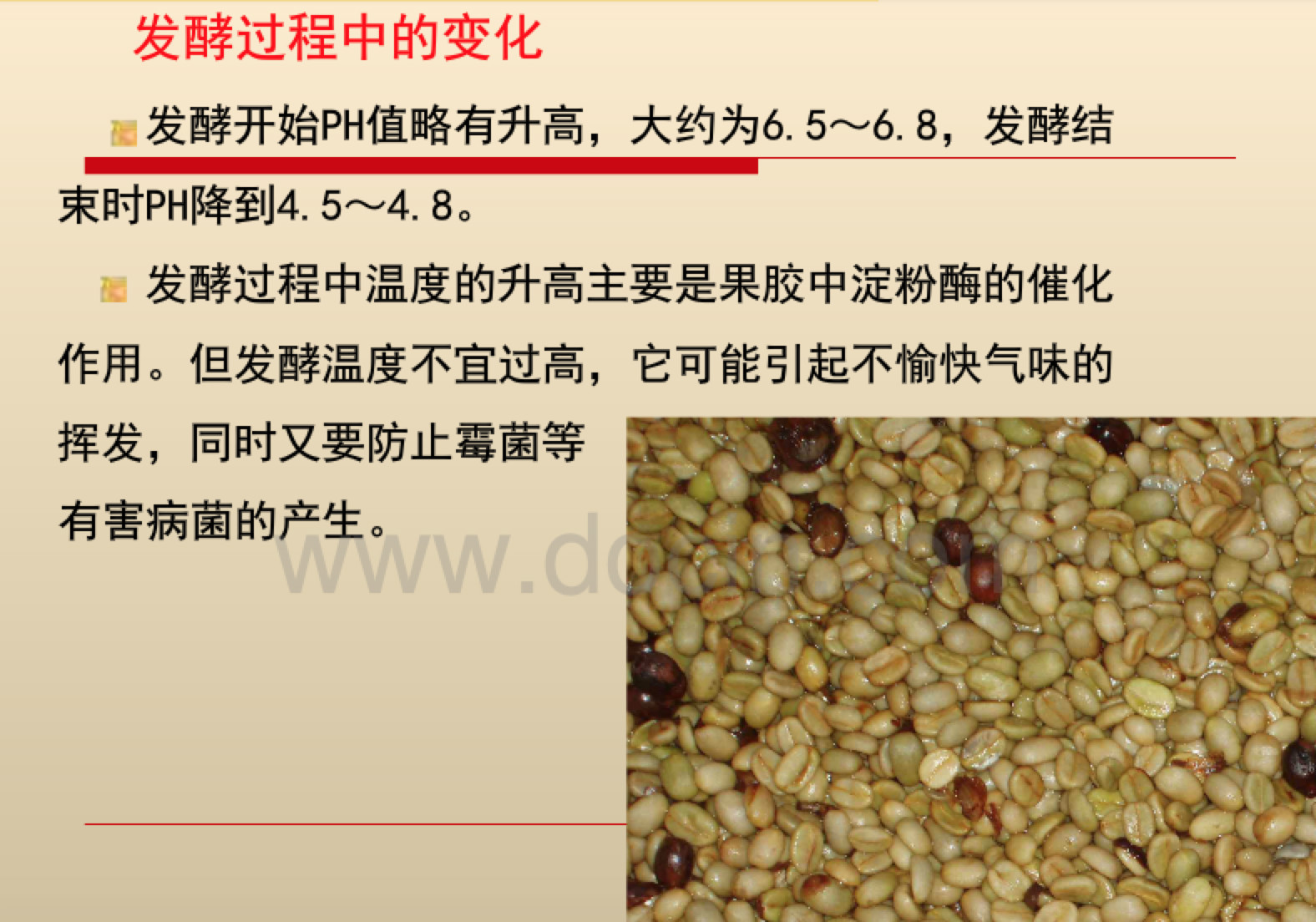

It is very important to grasp the timing of fermentation to ensure that the coffee beans are fermented properly and that the washing fermentation is to submerge the coffee beans and stop the natural fermentation.

Wet fermentation:

Do not add too much water, about 5 cm higher than bean noodles.

Take out the unplump beans floating on the top.

The speed of fermentation is affected by air temperature. Fermentation usually takes 1-4 days, 24 to 48 hours. If the temperature is high, the fermentation is fast.

Seeing that the outer shell is clearly visible proves that the coffee beans are almost ready to ferment.

At this time, the coffee can be washed, make sure that only clean water is used at this time, and then brush the coffee back and forth evenly.

Matters needing attention during fermentation:

Drying: after the washed bean with shell is drained, the moisture content is 52%, 53%, and dried in the sun. The moisture content of the bean must be reduced to 10% and 12%.

Drying thickness: generally not more than 5 cm

Table of appearance and moisture content of coffee beans at different stages of drying (refer to Institute of Agricultural Sciences)

Store the dried coffee beans with shells, which should not be stored for more than 6 months. The air humidity is 50-63%. The humidity is ideally below 20 degrees. Dry, ventilated, and finally wear off the sheep skin before the exit.

Honey treatment, honey treatment is the method of peeling off the pulp and drying the fruit with endocarp. Honey treatment process: the raw bean is made by sun drying with mucous membrane, and the honey treatment will be dried with a shelter.

Honey treatment process: selecting bean → to remove pulp → with pectin drying → shelling → selection and classification.

In general, the drying time of coffee depends on the local climate, temperature and humidity. The drying time of raw coffee beans treated with red honey is 2-3 weeks, usually due to weather or placed in a dark place.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Yerga Shefi Alomer Treatment Plant Sun-dried Local Native Coffee Flavor

Professional coffee knowledge exchange More coffee bean information Please pay attention to coffee workshop (Weixin Official Accounts cafe_style) Country Ethiopia origin Yega Xuefei Dilla Town altitude 1400 - 1800 meters varieties Ethiopia ancient excellent original species producer Aromer treatment method after full washing scaffolding sun drying YCFCU organization direct export washing batch. since 2008

- Next

Minas Djilas region, Brazil | Reunion Bourbon (also known as Lau) on the island of Reunion

Professional coffee knowledge exchange more coffee bean information please follow the coffee workshop (Wechat official account cafe_style) Brazil Minas | Djilas area tanning method | Reunion Reunion Island pointed bourbon (also known as Laurina, Leroy) flavor? When it comes to Arabica, it is actually like a big family, and there are many different members in the family, among which the one who has the greatest impact on the coffee world

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?