What is the difference between fine coffee and commercial coffee? what are the standards of fine coffee? what are the characteristics?

What makes boutique coffee so special? We know its quality is much better than commercial grade beans, but why? It was picked from the tree. Is the tree full of the unique and delicious features we like?

If only it were that easy!

The production of high-quality micro-batch boutique coffee requires a lot of detailed work. From fertilizers to shadows, from elevations to crops grown on miniature farms, all have an impact on the quality of coffee. However, once you decide where to plant what and with what, the effort will not stop. To produce boutique coffee beans, you must always pay attention to detail throughout the process-and there are three quality control points that can really change the final cup.

1. Cherry picker: go red!

Do you think picking cherries is a basic work? Think about it again. The frontline of quality control begins with these diligent people.

Traditionally, coffee pickers are required to pick all the cherries visible-green, yellow, red or even black. Yes, black. This is quantity over quality, because coffee is usually sold as a basic commodity rather than a luxury. With such a business model, the more you have, the more money you can get.

However, with the advent of the third wave of coffee, things are changing. Picking at the boutique coffee farm is taught to pick only red, ripe cherries. This is very important because underdeveloped or overdeveloped cherries will make the final cup sour or bitter. This is a difficult transition for the farm, because pickers usually pay based on the weight of the cherries picked. On boutique coffee farms, pickers are still compensated according to their weight, but they have to pay a certain premium to the pickers to make up for their weight loss and tedious work.

But no one is perfect, so outdated or outdated cherries do fall into sacks. As a result, some farms have taken it further and hand-screened red cherries picked throughout the day to remove all scattered red cherries. This ensures that only the best and most ripe cherries can enter the wet mill.

two。 Parchment Coffee: find those flaws!

After the cherries have been wet milled and dried to the best humidity, it is time for the next stage: shelling. This is where the second quality control inspection is located.

Why are there so many quality control checks? Well, even the most mature and reddest cherries can hide defects. They may look great with the naked eye, but they can't tell what's under the pulp.

Hand-pick the obviously flawed parchment and throw it into a pile of pulsatilla. Pasilla is a defective bean that, unfortunately, will still be sold on the market. This is what you usually find in commercial-grade coffee, and what most Colombians drink every day.

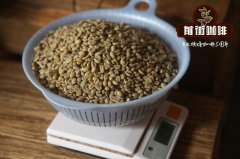

3. Green beans: the final stage

After shelling, put them in the final stage before baking: green. Once again, a quality control check is required. Parchment, like pulp, can hide defects. According to the SCAA standard, fine coffee must have zero major defects, so it is important to eliminate any defective coffee beans.

Traditionally, this last quality control point was done by hand, but now there are machines that can do the job. Manual selection is ideal because it provides employment opportunities for local communities.

However, it is not always the most time-saving-especially for large cooperatives that deal with a lot of work. As a small importer and exporter dealing with small micro batches, I focus on maintaining economic and social sustainability in the communities we work with, so I prefer traditional manual sorting methods. For others, machines may be a more feasible option.

Through the effective implementation of these three quality control points throughout the processing phase the quality of coffee beans will be significantly improved. So the next time you sit down and enjoy a cup of delicious boutique coffee, you will find that it is not only the beans themselves that make the coffee so delicious, but also the meticulous production and hard work of these quality control inspectors.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee varieties | Why Columbia Coffee Research Center attaches so much importance to hybrid coffee varieties

As far as coffee producers are concerned, F1 hybrids tend to be high-quality, rust-proof and high-yielding varieties-the golden trio. However, there is only one problem: their procurement is extremely difficult and expensive. However, the Starmaya variety can provide a solution. It is still in the final stages of testing, but it turns out that this F1 can solve many problems in the coffee industry: rust, short coffee.

- Next

Kenya Coffee Flavor and Taste introduction to the varieties of African and Kenyan coffee beans

In less than a century, Kenya has become home to no less than four new varieties. First, the Scott Lab (ScottLaboratories) identified the famous SL-28 and SL-34 of the 1930s. They combine amazing flavor and drought resistance.

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?