Authentic Jamaica Blue Mountain Coffee Bean production process, Trade and official Certification of Blue Mountain Coffee

Only coffee grown within the Blue Mountain as defined by law can be certified as Blue Mountain Coffee. It is not alpine coffee, Jamaican coffee or a mixture containing blue mountains, but 100% Jamaican blue mountain coffee. Then it is processed in the Mavis Bank coffee factory and needs a long process of inspection and cultivation before it can be received.

The real Jamaican Blue Mountain Coffee is officially planted at an altitude of 3000-5500 feet. It has to be certified by the Jamaica Coffee Industry Bureau to be the real Blue Mountain Coffee and is packaged in wooden barrels.

Blue Mountain Coffee is only produced in three producing areas: 1. Portland Portland 2. St. Andrews producing area ST.Andrew 3. St. Thomas producing area ST.Thomas

In 1967, Mr. Mr St. Clair Shirley founded Jamaica Coffee Co., Ltd. (JCC), a pioneer of Jamaican Blue Mountain Coffee. In Jamaica, St. Andrew, Portland and St. Thomas have established four manors, which are as famous as Mavis Bank and Wallenford manors: ST. Clouds,Cinchonia, Journeys end,and Stoneleigh estate .

It owns 3000 mu of land planted in the 910-1700m area of the Blue Mountain Mountains dedicated to growing Blue Mountain Coffee, and now General Manager DAVID SHIRLEY is Chairman of the Board of Directors of CIB, Jamaica Coffee Industry Authority. MTT Coffee has the supply, sale and after-sale of one-to-one Blue Mountain coffee beans at Journeys end and Stoneleigh Manor.

In addition to its own manor, JCC also has its own baking plant and local cooked bean brand, with a complete and mature quality control system. At the same time, JCC also instructs and trains surrounding farmers and coffee farmers to grow Blue Mountain Coffee to increase the overall production of Blue Mountain Coffee and enrich their own supply chain.

The coffee is collected from farmers only after the cherries are ripe-it's completely red. The berries on each farm are picked by hand and float in the water. If the floating berry has undeveloped legumes or insect pests, discard it. Farmers then bring the good coffee to one of the more than 80 MBCF collection points, where it floats again to ensure that only pre-floating coffee can enter the factory.

Collectors visit these warehouses every day and collect freshly floating coffee for pulping. The process begins in the late afternoon so that the coffee can be beaten soon after picking. Once at the factory, it is placed in a large storage tank and thoroughly inspected to eliminate any overfermented, green or pest cherries. It is then washed to remove mucus, a sugary substance outside the beans. The product left after washing is a creamy brown bean called wet parchment.

The wet parchment is then dried on a large concrete slab called barbecue. This can take up to five days, depending on the sunlight. During the peak rainy season, mechanical dryers are also used. The drying process involves bringing the moisture in the beans to a certain level. In the meantime, more assessments will be conducted to ensure that only the highest quality coffee beans pass.

The next step is to take a break. The dry parchment is now bagged and taken to the warehouse, where it can be stored for at least ten weeks. This is a critical stage of processing, at which some unique features emerge. Once the beans rest, they can shell.

Shelling is the place where the "shell" or shell is removed, and the world-famous mung bean appears. The shell is stored in a silo and used as fuel for wood dryers. After shelling, the beans are polished to remove the outer silver skin, and can now be sorted.

All coffee beans are classified and sold according to certain characteristics verified by the Coffee Industry Committee. Beans are graded according to size: I, II, III and Peaberry. Peas are monocotyledons or closed beans. Next, beans must pass rigorous taste, taste and color tests. The final step is to complete the final inspection by hand, checking each bean to eliminate any defects.

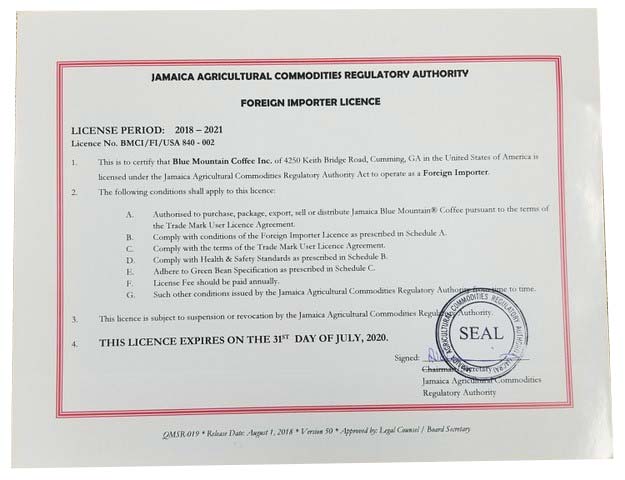

The coffee beans are then placed in buckets made of poplar and taken to the Coffee Industry Committee of Jamaica, which will inspect them and mark them as 100% Jamaican Blue Mountain coffee beans, ready to be exported to people licensed for purchase and distribution.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Yega Xuefei Coffee Farmers Cooperative Union YCFCU | Fruit Tintin, Waka Cooperative Bean Flavor and Taste characteristics

Yega Xuefei Coffee Farmers Cooperative Union YCFCU | Fruit Ding

- Next

Mavis Bank Blue Mountain Coffee Moon Family Story | Clifton Blue Mountain Coffee Bean NO.1 has special flavor.

Since the 18th century, Jamaican Blue Mountain Coffee has been widely known around the world, and its popularity increased significantly in the 19th century. The price of Jamaican Blue Mountain coffee continues to hit new highs. It is true that the output of blue mountain coffee is very small, and its growing environment is very strict on altitude. Blue mountain coffee 100% Jamaican blue mountain coffee. Then it was processed at Mavis Bank Coffee Factory.

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?