Two washing methods for Burundi coffee beans Burundi coffee processing station story and flow

Most coffee in Burundi is washed with water, but there are two methods of washing, namely, hand washing (washed) and coffee washing station washing (fully washed).

The hand washing marked "washed" refers to the complete manual removal of the sticky layer of the pericarp and pectin, the quality is quite inconsistent, because coffee farmers in Burundi either sell the fruit and the shell beans removed by hand to the water washing station, or sell it to the trader who buys the fruit. Farmers generally feel that the purchase price of the washing station is not real, and those who may be deceived must have more time and better bargaining space for the harvested fruit, which makes some coffee farmers prefer to do manual washing with peeling and pectin by themselves. The treatment is rough and uneven, and coffee farmers often deal with it by the side of the road with only their hands and without any tools. Of course, the Government does not encourage this. Coupled with the privatization of water washing stations and the encouragement of professionals to specialize in post-harvest treatment, the washing of water washing stations is called "fully washed" (FW will be marked on sacks). Although most washing stations produce commercial beans, the newly emerging boutiques of Burundi can only be found in intentional washing stations scattered everywhere, and it is better to touch less hand-washed raw beans marked "washed".

Coffee washing station and actual process description

Coffee farmers in Burundi live only on crops grown on land, and coffee trees are usually the only source of cash income. They sell coffee cherries to get cash to pay for their children's school and other expenses. Farmers can not handle the coffee cherries after harvest by themselves, so they can only sell them to the coffee washing station, which is set up from the actual demand. There are only a very small number of Central American-style coffee farms in Africa, and coffee farmers have only a small number of coffee trees, ranging from a few to more than 200, and they do not have the spare financial resources to buy small peeling and pectin machines, nor can they set up small water-washing and fermentation troughs. This is a necessary equipment for small farms in Central America or Colombia. Burundian coffee farmers can only harvest coffee cherries during ripening and send them to washing stations or sell them directly. To discuss the quality of coffee in Burundi, it is necessary to check the water washing station model, which is usually registered with all coffee fruits received daily (which can be referred to as daily collection, day lot). Looking at the scene, daily batches mixed with the fruits of all mine coffee farmers on that day could not clearly identify which coffee farmers this batch came from. Only the names of coffee farmers on the list could be used to trace the source of high-quality coffee. If you only look at the name of the washing station, it will be distorted or even disappointed. The washing station will process the fruit into shelled beans. Farmers can choose to join their own production cooperatives or decide to sell them to any washing station closest to their residence. Coffee cherries during the harvest season are sent to the washing station every day for processing, and they are sent on foot or by bike. Usually, the fruit received by the water washing station is coffee fruit picked by hundreds of farmers on the same day, which is mixed in the afternoon. After that, we began a series of continuous operations of peeling pectin, fermentation and washing, which is the whole-day production process of the washing station.

The refining process of high-quality batches in Burundi: a case study of the treatment plant process in Banja and Kayansa district

In a harvest season, each family sends about 500 kilograms of fruit, and each household produces less than 100 kilograms of raw beans a year. Banjia's coffee cherries are processed on the same day, and some of the processing plants will set up selection areas, allowing coffee farmers to screen their own unripe or overripe fruit. First, put the qualified fruit into a large tank, leave the density good by buoyancy screening, remove the unripe or light ones, then use a human machine to remove the pericarp and pectin layer, and then ferment the fruit in a human fermentation tank for 18 hours. The next day, the fruit of the previous day was fermented continuously in clean water for 18 hours, for a total of 36 hours. Then, the fruit guide cleaning channel is washed with clean water, and finally it needs to be soaked or go into the drying process, which is actually the Kenyan method of double fermentation.

Then the drying operation is carried out. In the first stage, shading and air drying is carried out to avoid hot direct sunlight, and the moisture content is reduced from the high humidity just left the fermentation tank to less than 40%, then moved to the scaffolding for natural sunlight, allowing the moisture content to reach 18% and then slowly reduce to 11%. The picture below is the solarization method.

The screened coffee fruits are spread on the scaffolding to bask in the sun, which is still a rare local treatment. From the first stage of the development of the fermentation tank, the fruit will accumulate higher, as the moisture content gradually decreases, the number of turning will increase, while the refined batch, its height is even less than 2 cm.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Advantages of growing Coffee in El Salvador International Coffee Trade Export Volume and Development Strategy

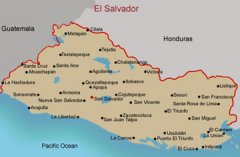

When it comes to El Salvador, no one must have any impression. What is the story behind such a mediocre and even some backward country with excellent coffee beans? Today, let's go to Li, oh, Sister. The Republic of Wadow is located in Central America, opposite Guardia and Honduras in the north, and the Pacific coast is bounded by the west and south. Yes

- Next

El Salvador's unique coffee varieties, flavor, coffee export advantages and coffee industry crisis story

The French Vado enjoys the world with some special varieties and specific local varieties: Bourbon, the bourbon abrupt change of Pacas, and the mixed pacasera (mentioned in Nicaragua, Pacamara, a mixture of Pacas and Maragogype, is a large coffee bean), allowing growers to pass through the biography that highlights the fruit itself.

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?