Brief introduction of Kenya processing Plant Gakuyuini and Coffee Bean processing Thirikwa Farmers' Cooperation

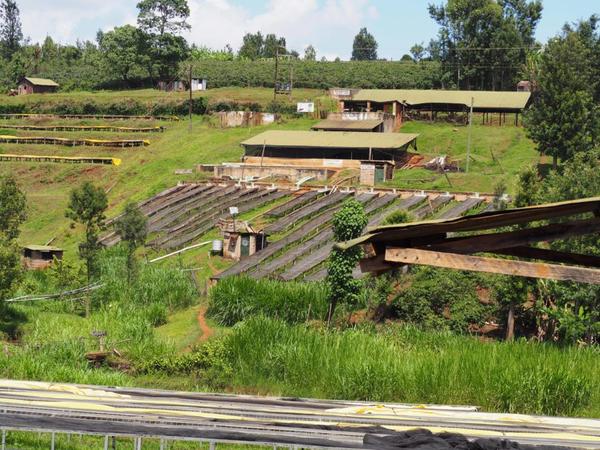

Kenya's coffee industry is famous for its systematic cooperation system of production, processing and marketing. About 70% of Kenyan coffee is produced by small-scale growers. Qianjie pays special attention to the Gakuyuini processing station with you today.

Coffee grade: AB full water wash

Farm / cooperative / station: Gakuyuini processing station

Varieties: SL28, SL34

Processing: full washing

Altitude: farmers-1500 to 1900 m above sea level; washing station-1600 to 1700 m above sea level

Owner: member farmers transport cherries to Gakuyuini coffee processing station

Subregions / towns: Kerugoya and Kianyaga, Kirinyaga

Region: central Kenya

Farm size: an average of 250 trees

Bag size: 30kg

Harvest month: central Kenya: may to July (precocious) | October to December (late ripening)

Today, more than 600000 small farmers with less than five acres account for 99 per cent of Kenya's coffee growers. Their farm covers more than 75% of the total coffee planting area and produces nearly 70% of the country's coffee. These farmers are organized into hundreds of farmers' cooperatives (FCS), all of which run at least one factory. The rest of the annual output is planted and processed by small, medium and large land. Most of the larger estates have their own laundry stations.

Of the more than 1500 active members who contribute cherries to Gakuyuini Washing Station, more than 1/4 (more than 670) are women. Together they harvest about 250 tons of cherries a year and transport them to the station.

The station is owned and managed by Thirikwa Farmers' Cooperative. The cooperative is headed by five democratically elected board members. Farmers who ship cherries to Gakuyuini usually own less than a hectare of land each. On this small piece of land, they grow livelihood and cash crops all year round to support their families. The average farmer has about 250 coffee trees, which are usually intercropped with other crops. Although low yields may mean reduced profits, many farmers grow boutique coffee as a way to increase the value of each cherry picked. Farm labour is usually provided entirely by family members, which usually makes it easier to maintain professional planting and picking practices. Many farmers also grow tea, corn and beans to consume or sell in the local market for extra cash income.

Harvest and after harvest

Farmers pick ripe cherries by hand and send them to the Gakuyini factory for processing on the same day. In the factory, cherry sorting takes place before pulping, and ripe cherries are separated from immature, overripe and foreign bodies.

The factory uses clean river water for processing and recycles the water before it is discharged into the seepage pit. The coffee is then dried on an elevated bed and then sent to a dry mill for secondary processing.

Farmers selectively pick ripe cherries and transport them to the Gakuyuini washing station. Cherries are sorted at the entrance, in which immature and overripe, as well as any foreign matter are removed.

Then add the sorted cherries to the hopper and beat them. The cherry pulp is fermented for 12 to 16 hours, then washed with clean water to remove any residual mucus. When parchment dries on an elevated bed, the wet parchment is sorted and any remaining damaged beans are removed. Rotate regularly to ensure uniform drying and cover during the hottest days and nights to prevent cracking and / or condensation. The drying time is usually about two weeks, depending on the weather at that time.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

History and Development of Bourbon Coffee beans Flavor of Red Bourbon Coffee beans in Tianzhi Manor of Nicaragua

Bourbon is one of the most culturally and genetically important varieties in the world. It is famous for its excellent quality in cups at the highest altitude. The coffee in bourbon is higher, the leaf tip is green, and the size of beans is relatively average. It has the potential of high quality at high altitude. But it is easily affected by coffee leaf rust and nematode disease and the yield is very low. French missionaries in the early 1700s

- Next

Top five Coffee beans Certification UTZ Fair Trade Bird friendly Certification Clifton Manor Rain Forest recognition

Coffee certification is everywhere in grocery stores, restaurants, and even offices! Today's consumers have the right to know whether their coffee beans are certified, which provides consumers with a variety of third-party guarantees. They can demonstrate environmentally friendly agricultural practices and can achieve organic certification all the time. They can ensure that child labor is not involved in the production of coffee. Some plans are more focused.

Related

- Detailed explanation of Jadeite planting Land in Panamanian Jadeite Manor introduction to the grading system of Jadeite competitive bidding, Red bid, Green bid and Rose Summer

- Story of Coffee planting in Brenka region of Costa Rica Stonehenge Manor anaerobic heavy honey treatment of flavor mouth

- What's on the barrel of Blue Mountain Coffee beans?

- Can American coffee also pull flowers? How to use hot American style to pull out a good-looking pattern?

- Can you make a cold extract with coffee beans? What is the right proportion for cold-extracted coffee formula?

- Indonesian PWN Gold Mandrine Coffee Origin Features Flavor How to Chong? Mandolin coffee is American.

- A brief introduction to the flavor characteristics of Brazilian yellow bourbon coffee beans

- What is the effect of different water quality on the flavor of cold-extracted coffee? What kind of water is best for brewing coffee?

- Why do you think of Rose Summer whenever you mention Panamanian coffee?

- Introduction to the characteristics of authentic blue mountain coffee bean producing areas? What is the CIB Coffee Authority in Jamaica?