History of coffee beans the birth of coffee beans 2

Coffee bean processing

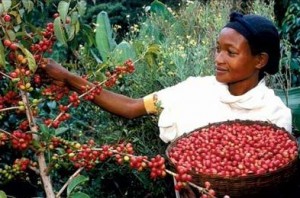

When the hard-working bean farmers antagonize the picking of mature and bright red coffee "cherries", the magic adventure of coffee beans begins. To convert the coffee fruit into raw coffee beans, the peel and pulp of the coffee fruit need to be removed, leaving seeds or beans, and drying. This refining process usually has two main processing methods: washing (wet method) and drying (dry method) washing or drying can produce the highest quality coffee. Generally speaking, water-washed coffee has distinct acidity and consistent flavor, while dry coffee has lower acidity and more varied flavor. Colombia, Kenya, Costa Rica, Guatemala, Mexico, and Hawaii all use water washing methods. Most of the coffee produced in some countries, including Brazil, Ethiopia and Indonesia, is dried, but some water-washed coffee is also produced. Wet method cherries are picked, including ripe, overripe and unripe cherries. These cherries must be treated separately and are mixed with many sundries, such as stones, leaves and so on. So these cherries have to be washed and placed in a large trough full of water for preliminary classification. The best coffee has a high density, so it sinks into the water. On the other hand, overripe cherries will surface and can be easily classified.

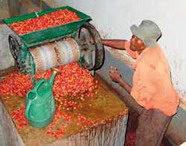

Remove the peel and pulp of the coffee cherry and soak it in a large cement tank filled with water. After fermentation, the water-washed coffee will have a distinctive and clear flavor. The fermented coffee beans are washed with clean water, then removed from the water and dried in the sun or machine. Finally, the peel and silver peel are removed by a sheller, which can be screened and divided into different grades of raw coffee beans.

The advantage of water washing is that it has good luster, less foreign bodies and slightly better sour taste. It is used in Colombia, Mexico and Guatemala. Disadvantages: bad time management will produce bad smell and special sour smell.

1. Select beans and remove spoons 2. Remove the outer skin and pulp 3. Ferment

4. Wash 5. Dry 6. Shedding

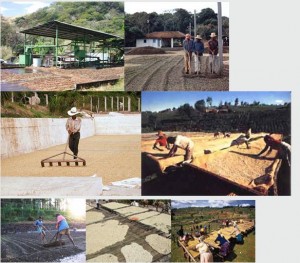

Dry method is usually used in more extensive, small-scale estates or in places where water resources are relatively scarce. The treatment is to spread the coffee cherries widely on the exposure field for two weeks and sweep them with a rake several times a day so that the coffee beans can be dried more evenly. When dried, the coffee beans are separated from the skin, and the dried pulp and peel are removed by a sheller, then screened and divided into different grades. The advantage of drying is that it has a soft sour taste and a peaceful bitter taste. This method is used in Brazil, Ethiopia and Yemen. Disadvantages: vulnerable to weather, defective beans and foreign bodies are more likely to mix.

Later, a new so-called semi-washing method came into being, which omits the two procedures of fermentation and washing in the washing method, that is to say, the pulp of coffee is removed naturally, and this method is only suitable for specific regions of some countries (such as Cerrado, Silado District of Brazil), where there is a long drying period in the climate before it can be used to deal with local coffee. The coffee produced by this method is sticky, and the mucus is not removed with fermentation in the tank. Therefore, the coffee produced by this semi-wet treatment contains the characteristics of both washing and drying. The acidity, sweetness, seasoning, and aroma of this coffee are soft and not as strong as those produced by pure drying or washing.

The selection and grading of coffee depends on the particle size and concentration of beans, as well as the number of defective beans in a pound (broken beans under ripe beans, etc.). Like the best wine, the careful handling and selection of professional coffee in the production process can be seen in the quality of the beans, because the product will have a unique representation, which represents the origin, climate and growers. Hierarchical processing method: 1. Get raw bean A. Wet treatment: the endocarp was crushed off B. Dry treatment: grind off the fruit shell 2. Removal of impurities: stone, dust, endocarp or shell debris use air separator to adjust wind speed and separate foreign bodies and other impurities. Remove bad beans, such as broken beans, stunted beans, pest beans, diseased beans, overripe beans and unripe beans, using air separator to separate bad beans with different specific gravity and weight (broken beans, overripe beans, unripe beans)

Using artificial vision or computer color sorting machine to separate bad beans with little difference in specific gravity and weight but with color difference (insect infested beans, diseased beans).

4. Size sieve: a series of sieves from small to large to separate raw beans of different sizes. purpose: to make the size of raw beans uniform, conducive to the baking operation, and improve the value of raw beans.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee beans History the birth of coffee beans

The lifetime of a coffee tree takes 3-5 years from planting to fruiting. 6-10 years of coffee trees are the most likely to bear fruit, about 15-20 years, is the harvest period. Coffee trees are usually bred in nurseries and grow into saplings, and then moved to coffee farms a year later, in full compliance with the way the Arabs planted and cultivated coffee trees. Coffee trees will continue to decline in the first four or five years of growth.

- Next

History of coffee beans birth of coffee beans 3

Different washable coffee and dried coffee the coffee produced by washing or drying coffee actually has its own characteristics, and there is no question of which is better or worse. However, generally speaking, washed coffee has less impurities and defective beans, and the appearance of beans is cleaner, neat and of certain quality, so it is well received by Europe and the United States. But appearance is not equal to

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?