Coffee roasting specific analysis of coffee roasting techniques and degree of selection of French coffee roasting

Coffee roasting is a process of high temperature decomposition (Pyrolysis), which completely changes the substance inside the raw bean, produces new compounds, and recombines to form aroma and mellow flavor. This effect only occurs at high temperatures, and decomposition cannot be caused if only low temperatures are used.

In fact, in the coffee processing process, baking is the most rare step, it is a kind of science, but also a kind of art. The baking process is divided into three stages:

Dehydration, in the early stage of baking, raw beans begin to absorb heat, and the water inside gradually evaporates. This is, the color gradually changed from cyan to yellow or light brown, and the silver skin began to fall off, you can smell the faint smell of grass. The main function of this stage is to remove water, but the baker will make good use of the temperature of the water and control it properly so that it will not evaporate too quickly. When the water reaches the boiling point, it turns to steam, when the internal material is fully heated, and the water begins to evaporate, draining the outside of the beans.

Decompose at high temperature, bake to about 160 degrees, the water inside the bean evaporates into gas, and begins to discharge the outside of the coffee bean. At this time, the interior of the raw bean changed from endothermic (Endothermic) to exothermic (Exdothermic), and the first burst sound appeared. After the first burst, it turns to endothermic again, when the internal pressure of the coffee bean is extremely high, up to 25 atmospheric pressure. Heat and pressure begin to deconstruct the original tissue to form new compounds that create the taste and taste of coffee. When it reaches about 190 degrees, the conversion between endothermic and exothermic occurs again. Of course, high temperature cracking continued to occur, coffee beans changed from brown to dark brown, and gradually entered the stage of heavy roasting.

Cooling (Quenching), coffee must be cooled immediately after roasting, quickly stop the high temperature cracking, and lock the flavor. Otherwise, the high temperature in the beans will continue to act and will burn off the aromatic substances. There are generally two cooling methods, one is air-cooled, the other is water-cooled. The air-cooled type is slow, but it is clean and does not pollute, and it can retain the mellow flavor of coffee, so it is used for fine coffee. Water-cooled coffee beans are sprayed with a layer of water mist on the surface of coffee beans, causing the temperature to drop rapidly, requiring precise calculation, and increasing the weight of roasted coffee beans, generally used in commercial coffee roasting.

Burst sound, raw beans from endothermic to exothermic, the internal gas out of the body, will form an obvious sound. The first time is louder, crisp and scattered, and the second is quiet, meticulous and concentrated. Because of the high correlation between popping sound and temperature, it can fully represent the baking temperature, which is an important basis for bakers to judge the baking degree.

The changes caused by baking are very complicated, and although scientists continue to study and analyze them, they are still unable to get a glimpse of the whole picture. There are roughly the following changes:

Weightlessness: the moisture content is reduced from about 13% to 1%, and the weight loss rate is about 12% 21%. The higher the baking degree, the more weightlessness.

Volume expansion: after baking, the volume of coffee beans will increase by more than 60%.

Pore enlargement: the cell wall of raw bean is hard and the cell pore is closed, so it is not easy to deteriorate. But after baking, the cell wall becomes fragile, the cell pore is enlarged, and it is easy to lose the internal material.

Formation of carbon dioxide: high temperature decomposition causes the carbohydrates inside the coffee bean to decompose and combine with other substances to form a large amount of carbon dioxide, which resides inside the coffee bean.

Change the organizational structure: after baking, carbohydrates dropped sharply from 58.9% to 38.3%, and acids (fatty acids, tannins, chloric acid, etc.) decreased from 8.0% to 4.9%. Under the action of high temperature pyrolysis, these substances are reorganized and transformed into caramel, carbon dioxide and some volatile substances. Among them, caramel accounts for 25% of the quality of roasted beans, forming the sweet taste of coffee. Fat accounts for 16.2% of raw beans and increases to 17% after baking, which is the source of mellow taste and consistency. Caffeine levels barely changed. Therefore, the bitterness of re-baked coffee does not come from caffeine.

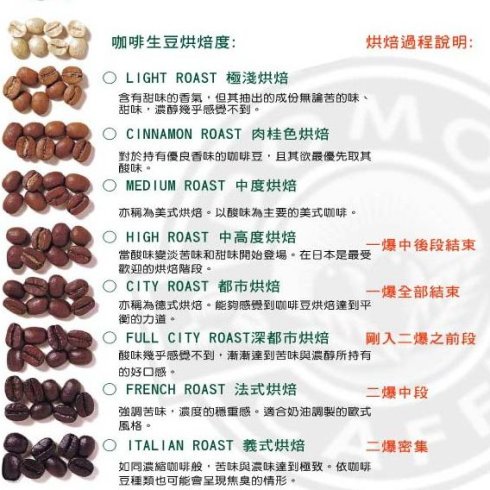

Baking degree, Pacific region differentiation method:

Light Roast (light baking): it still has the smell of grass, no aroma and mellow taste.

Cinnamon Roast (cinnamon roasting): coffee beans turn cinnamon.

Medium Roast (medium baking): has a strong sour taste.

High Roast (High Color Baking): sour, bitter and sweet begin to strike a balance.

City Roast (city baking): baked to the first explosion, just about to enter the second burst sound.

Full City Roast (city-wide roasting): when the second explosion is in progress, it is a favorite of select coffee roasters.

French Roast (French baking): very bitter.

Italian Roast (Italian roasting): the raw material of Italian espresso.

The National Fine Coffee Association (SCAA) uses Elon instruments to determine and analyze the color of coffee and the degree of caramel coking. Set black to 0 and white to 100, which is divided into 8 equal parts, representing 8 baking levels.

Source:

The blog of Mavericks Coffee

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee bean roasting theory definition of various baking degrees and taste problems effect of roasting degree on flavor

Let's talk about the definition of various baking degrees and taste. In the United States, the degree of roasting has long been defined by Cinnamon (shallow roasting), City (shallow roasting), Fully City (deep roasting) and Dark roast (heavy deep roasting, including Italian and French). However, the American preference for coffee flavor has always been strong in the west and light in the east, so on the west coast.

- Next

Coffee roasting principle: an introduction to the principle of different degrees of coffee roasting by heat conduction, convection and radiation

To do a good job in baking, every production link can not be ignored, the selection of materials should be fastidious, the weighing of materials should be accurate, and the operation should be careful. Baking is a science. To understand the principle of baking, we must first understand the three ways of heat conduction, convection and radiation. Conduction refers to when the heat is transmitted by the heat source, causing the surrounding molecules to vibrate and release heat, gradually moving from the high temperature to the low temperature. Conduction of stainless steel

Related

- Beginners will see the "Coffee pull flower" guide!

- What is the difference between ice blog purified milk and ordinary milk coffee?

- Why is the Philippines the largest producer of crops in Liberia?

- For coffee extraction, should the fine powder be retained?

- How does extracted espresso fill pressed powder? How much strength does it take to press the powder?

- How to make jasmine cold extract coffee? Is the jasmine + latte good?

- Will this little toy really make the coffee taste better? How does Lily Drip affect coffee extraction?

- Will the action of slapping the filter cup also affect coffee extraction?

- What's the difference between powder-to-water ratio and powder-to-liquid ratio?

- What is the Ethiopian local species? What does it have to do with Heirloom native species?