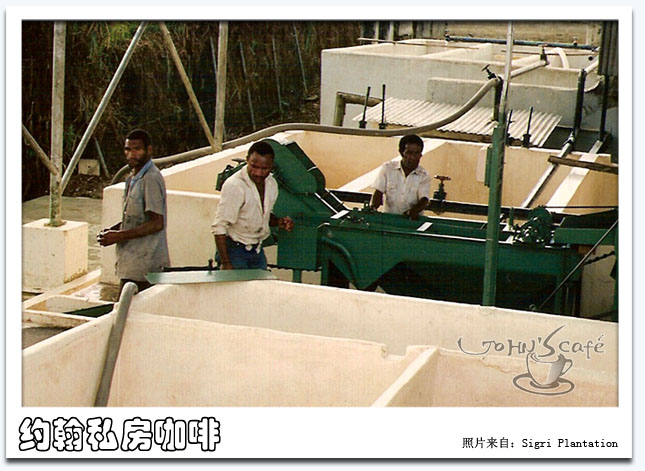

Primary processing of coffee washed coffee in Sigri farm

Having nothing to do, I was looking for some information about Sigri farm coffee in Papua New Guinea. I found these photos and information on the Gimmetries Coffee website.

Sigri Plantation is located in the Papua New Guinea highlands. Growing conditions here are well-suited for coffee: about 5200 feet above sea level, with a cool climate and plenty of rainfall.

Sigri Farm is located in Papua New Guinea, where the environment is very suitable for coffee growth, about 5200 feet (about 1600 meters) above sea level, the climate is cool and rainy.

"Processing" or "milling" is the way farmers separate the coffee bean from the pulpy fruit around it. The Sigri Estate has been refining its coffee processing method for over fifty years.

Through treatment, workers separate the pulp of coffee berries from seeds (raw coffee beans). Sigri Farm has been using traditional methods to handle coffee for more than 50 years.

Sigri uses a classic processing method: fully-washed and sun-dried. Processing the coffee immediately after harvest ensures a clean flavor in the final cup.

Sigri uses the traditional washing method to treat the coffee, that is, the coffee pulp and seeds are separated by complete washing immediately after picking, and then dried. This treatment ensures the clear and clean taste of sigri coffee.

The beans are washed three times over a 72-hour period. In between washings, they are held in fermentation tanks, which helps to break down the pulp around the bean. Once all the pulp is removed, the beans are soaked one last time in fresh water.

After 72 hours of washing and fermentation, the pulp is gradually separated from the seed. After the pulp is finally separated from the seed, the coffee beans are washed and soaked for the last time.

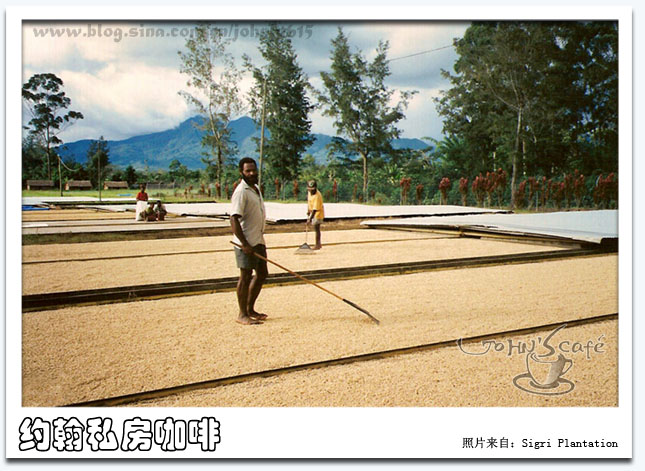

The beans are spread onto wide patios to dry in the sun. Over the next several days, the beans will be turned over with rakes make sure every last bean is dry. Finally, the coffee is ready to be sorted, shipped, and roasted. The final cup is deep and sweet, with an earthy flavor.

The coffee beans (soaked for the last time) are spread evenly on the drying ground to dry. Over the next few days, beans are often sown to ensure that each bean is completely dried. Beans can then be hand-graded, transported and baked according to the standard. Finally, the sigri in our cup is the sweet coffee with a touch of earthy aroma.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee processing Coffee beans processing

1. To remove the peel and most of the pulp mechanically or manually. 2. Fermentation removes mucus and membrane from the core by fermentation. Since the length of fermentation affects the flavor of coffee, each manufacturer has its own fermentation time. 3. Drying drying method is mainly divided into natural sun and natural air drying. Excessive moisture content is easy to cause coffee beans to mold and grow worms

- Next

Vibrating screen is used to select coffee beans and peanuts in the initial processing of coffee.

I saw on the Internet yesterday that someone asked if the vibrating screen could screen peanuts and coffee beans, and the answer was yes. In the following, some problems and solutions of vibrating screen in screening these two materials are discussed. First of all, customers need to know the number of peanuts and coffee beans, and then choose the appropriate sieve, which is like screening peanut and coffee beans.

Related

- Guji coffee producing area of Guji, Ethiopia: Humbela, Shakiso, Wulaga

- What is the most expensive variety of Qiloso in BOP multi-variety group?

- How to store the coffee beans bought home?

- Why are Yemeni coffee beans so rare now?

- Ethiopian Sidamo all Red Fruit Sun Sun Santa Vini Coffee beans

- SOE is mostly sour? What does it mean? Is it a single bean? what's the difference between it and Italian blending?

- Is Italian coffee beans suitable for making hand-brewed coffee?

- How to choose coffee beans when making cold coffee? What kind of coffee beans are suitable for making cold coffee?

- Just entered the pit to make coffee, what kind of coffee beans should be chosen?

- Can only Japan buy real Blue Mountain Coffee? What are authentic Jamaican Blue Mountain coffee beans?