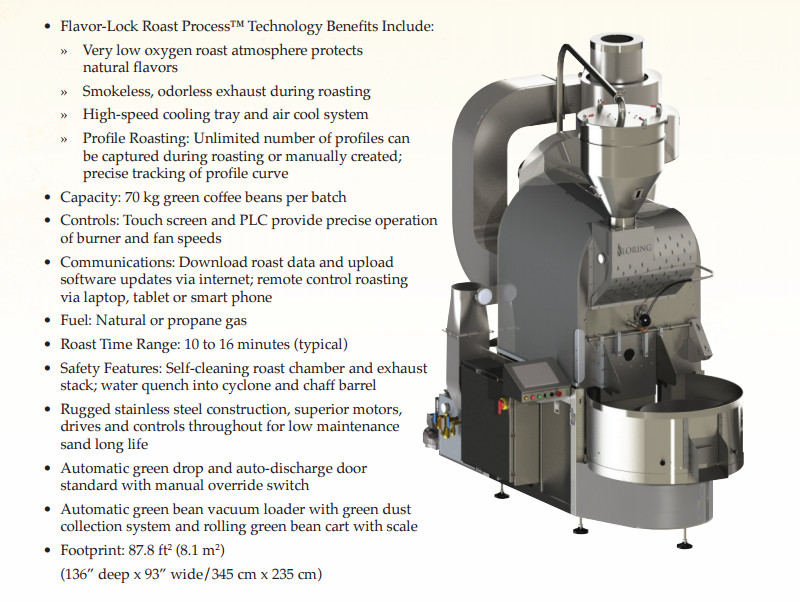

"LORING" intelligent coffee roaster-S70 PEREGRINE

"LORING" intelligent coffee roaster solves two problems that have not been solved in traditional roasters: one is the control of the roasting process, and the other is the smoke removal problem, so as to achieve smoke-free roasting. Its unique flavor lock baking process (Flavor-Lock Roast Process™) Intelligent control patented technology, is the most advanced coffee roasting technology in the coffee roasting process so far, it creates a "closed loop" roasting environment, removes oxygen from the heated gas, but at the same time increases the humidity of the hot gas, not only the bean yield is higher, more importantly, the roast taste is better; Its unique silver skin, smoke separation collector, on the one hand, the silver skin will be completely separated and burned, so that the silver skin collector is very clean, clean-free, to avoid silver skin burning fire, on the other hand, the smoke will be converted into high temperature steam and then enter the baking bin again, thus forming a "closed" hot air circulation system, not only smokeless baking, oxygen-free baking, but also greatly save energy.(Experimental data show that it is 80% more energy efficient than traditional roasters--this is quite a remarkable improvement, according to the manufacturer's calculation, based on US data statistics, after using Loring coffee roasters, gas alone can save 30,000 US dollars a year). Because only a small amount of excess hot gas is discharged from the traditional "exhaust pipe" of the Loring roaster, there is no scale on the pipe wall (there are scales formed by coffee oil and silver skin on the exhaust pipe wall of the traditional roasting system), thus solving the traditional roasting system. Due to its "closed" hot air circulation system, roasting will not be affected by environmental factors (temperature, humidity) brought about by weather changes, regardless of spring, summer, autumn and winter, the roasting environment in its roasting bin will not be affected, thus ensuring the roasting of coffee with consistent taste. LORING coffee roasters are loved by many roasters because they produce coffee that tastes cleaner and more lively. Its computer touch screen control system allows roasters to easily control every minute of coffee roasting, allowing roasters to easily reproduce coffee with consistent taste. Finally, it makes sense that all Loring coffee roasters sold can be linked to the Internet, so manufacturers can remotely monitor, guide roasting, diagnose problems, and users can remotely control and roast coffee via the Internet.

CAPACITY

Batch = 70 Kg (154 LB) Max; can run batches down to 15 Kg (33 LB)

8 hour shift = up to 2000 Kg (4000 LB)

52 weeks @ 40 hours/week = up to 600 tons

KEY BENEFITS OF FLAVOR-LOCK ROAST PROCESS™ TECHNOLOGY

Patented single-burner design = smokeless roasting

Computer-controlled, closed-loop, oxygen-free roasting = absolute repeatability of every roast

Roast times variable from under 10 minutes to over 16 minutes

Capture and download precise roast profiles and notes real time

High-speed cooling prevents baking and helps lock in flavor

UTILITIES

Electricity – custom wired to customer specifications in any country

Fuel – Natural Gas or Propane

Compressed Air

Water

Internet hookup for data upload, software updates and remote service assistance

CONTROLS

Touch screen operation

Optional remote control via iPad or other smart device with Internet hookup

Parametric PLCs for absolute precision

Automatic mode controls green bean drop, roasted bean discharge, cooling tray

Bean trier; True-color inspection lamp

MECHANICAL FEATURES

Footprint: 88 square feet (8.1 square meters)

136” deep X 93” wide (345 cm x 235 cm)

Rugged, beautiful stainless steel construction

Highest quality motors and drives = low maintenance and long life

Vacuum green bean lift

Roving bean truck with built-in digital scale

SAFETY FEATURES

Self-cleaning roast exhaust stack = no stack fires

Clutched operation of cooling tray paddles to help prevent personal injury

Computer controlled quench in cyclone and chaff bucket

INSTALLATION REQUIREMENTS

12 ft. minimum ceiling clearance

3 ft. recommended clearance to walls

8 inch ID, insulated double-wall stack

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

The principle and types of coffee roasters are divided into commercial roasters and household roasters.

First, commercial baking machine The manufacturing principle of commercial baking machine is mainly divided into three categories: direct fire type, semi-hot type, hot air type. At present, the latter two roasts have the best effect and are the mainstream in the specialty coffee market. 1, direct fire type The earliest baking tools used by humans are direct fire type, that is, the hot roller is baked with fire, and then the heat is transferred to the raw beans in the barrel. Although, the motor keeps turning the drum, turning

- Next

"LORING" intelligent coffee roaster-S35 KESTREL

The LORING intelligent coffee roaster solves two difficult problems that have not been solved in the traditional roaster: one is the control of the baking process, the other is the problem of smoke removal, so as to achieve smoke-free roasting. Its unique flavor lock roasting process (Flavor-Lock Roast Process) intelligent control patent technology is by far the most advanced coffee roasting technology in the coffee roasting process, which creates a

Related

- What is the Philharmonic pressure? How to use Philharmonic pressure to make delicious coffee

- Why does a hand grinder have more fine powder than an electric grinder?

- In addition to the hot mom, what is the difference between the versions of EK43 | ditting and Mahdi ek43?

- What kind of equipment do you need to make coffee by hand? Introduction to novice starter cooking equipment tools

- Espresso needs to be ground how thick and thin scale entry Italian Coffee Machine Bean Grinder investigation and Grinding course

- How much does it cost to open a small private cafe? How much does it cost to learn coffee? How to operate it?

- The difference between the flavor characteristics of hand-brewed coffee and coffee maker is hand-brewed coffee really better than coffee maker? Can I use a coffee machine to make coffee beans by hand?

- The difference between 01 and 02 of hario v60 filter cup what is the difference between 01 and 02 filter cup opening and cooking flavor

- What's the difference between the smart cup and the French kettle? Which is better, the French kettle or the Smart Cup?

- What's the difference between a smart cup and a V60 filter cup? The difference between the taste of smart cup and hand-brewed coffee