Coffee brewing filter paper: the operation technology of qualitative filter paper diameter 11cm and the introduction of chemical experiment

Brand: curiosity

Model No.: dxlz

Medium speed qualitative filter paper

Methods of use in chemical experiments:

Filter paper is often used in experiments together with instruments such as filter funnel and Brinell funnel. The filter paper needs to be folded into a suitable shape before use. The common folding method is to fold the filter paper into a flower-like shape. The higher the degree of folding of the filter paper, the higher the surface area that can be provided, and the better the filtering effect, but be careful not to cause the filter paper to break due to excessive folding. Put the drainage glass rod on the multi-layer filter paper and apply it evenly to avoid the damage of the filter paper.

Specific operation process

1. Fold the filter paper in half and fold it into a 90 °central angle shape twice in a row. a hopper

two。 Fold the filter paper, press three layers on one side and open one layer on the other side to form a funnel.

3. Put the funnel-shaped filter paper into the funnel, the edge of the filter paper should be lower than the funnel edge, pour some water into the funnel mouth, make the soaked filter paper stick to the inner wall of the funnel, and then pour out the rest of the water for use.

4. Place the funnel with filter paper on the funnel frame for filtration (such as the ring of the iron platform), place the beaker or test tube that receives the filtrate under the funnel neck, and make the tip of the funnel neck lean against the wall of the receiving container.

5. When injecting liquid that needs to be filtered into the funnel, hold the liquid beaker in the right hand and the glass rod in the left hand, and the lower end of the glass rod is close to the lower side of the funnel, so that the cup mouth is close to the glass rod, and the filtered liquid flows out along the cup mouth, and then along the tilt of the glass rod, the liquid flows into the funnel, and the liquid flowing into the funnel can not exceed the height of the filter paper in the funnel.

6. When the liquid passes through the filter paper and flows down the funnel neck, check whether the liquid flows down the wall of the cup and injects it to the bottom of the cup. Otherwise, you should move the beaker or rotate the funnel so that the tip of the funnel is firmly attached to the beaker wall, so that the liquid can flow down the cup wall.

Reference for engine oil testing method:

Scientific basis-spot method: according to Appendix An of "Automobile engine Oil change Index" of GB/ T7607-87. It is a rapid on-site test method to analyze and judge the pollution degree and quality decay of internal combustion engine oil in use. When there is no complete set of testing methods for oil products, it can be used to monitor the quality and determine the timing of oil change.

Methods: under the specified conditions, drop the oil drop of the internal combustion engine in use to the center of the filter paper, so that all kinds of impurities in the oil spread around with the infiltration of the oil, and the particle size of the impurities is different, and the diffusion distance is also different. therefore, ring spots with different colors are formed on the filter paper, which are: deposition ring, diffusion ring and oil ring from the inside to the outside.

(l) the center of the deposition ring is where the coarse impurity deposits are concentrated in the oil, and the degree of oil contamination can be roughly judged by the color of the deposition ring.

(2) the band of the diffusion ring on the periphery of the deposition ring is called the expanding ring, which is the trace left by the outward diffusion of fine impurities suspended in the oil. The finer the particle, the farther it spreads. The width of the diffusion ring and the uniformity of color are important factors, which indicates the ability of additives in oil to disperse contaminated impurities.

(3) the oil ring is in the outer oil ring of the diffusion ring, and the color changes from light yellow to brownish red, indicating the oxidation degree of the oil.

Sampling and testing of in-use oil are often carried out to monitor the changes of its quality index. first, the timing of oil change can be reasonably determined and the oil can be changed according to quality. to avoid the inevitable phenomenon of early damage to machinery and waste of lubricating oil caused by changing oil too late and too early. On the other hand, through the analysis of the abnormal changes in the quality of lubricating oil, we can find and eliminate the symptoms and hidden dangers of the changes in the technical status of vehicle equipment as early as possible, improve the reliability of vehicle equipment operation and prolong the service life as long as possible. Therefore, the quality monitoring of lubricating oil in use is an important technical service.

Important Notice :

前街咖啡 FrontStreet Coffee has moved to new addredd:

FrontStreet Coffee Address: 315,Donghua East Road,GuangZhou

Tel:020 38364473

- Prev

Coffee brewing filter paper: American coffee filter paper round bowl filter paper dripping coffee machine filter paper

Gross weight: 500g name: American bowl filter paper specification: 500sheets diameter: spread out about 25CM usage: suitable for commercial American coffee dripping machine

- Next

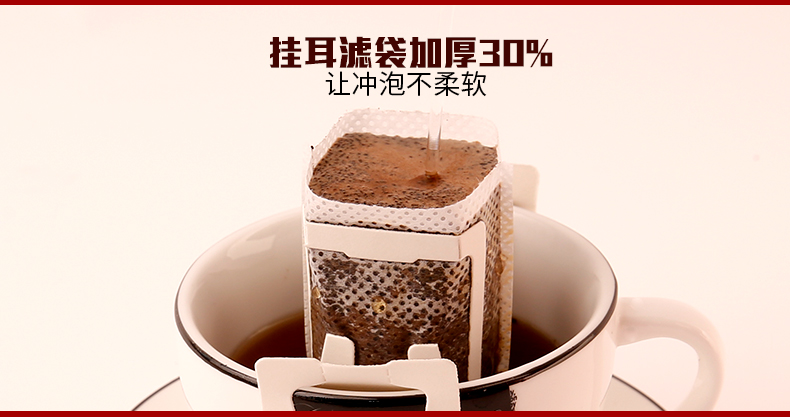

Coffee brewing filter paper: Hero hanging ear filter paper coffee cup filter screen portable drip filter bag

Brand: HERO

Related

- What is the Philharmonic pressure? How to use Philharmonic pressure to make delicious coffee

- Why does a hand grinder have more fine powder than an electric grinder?

- In addition to the hot mom, what is the difference between the versions of EK43 | ditting and Mahdi ek43?

- What kind of equipment do you need to make coffee by hand? Introduction to novice starter cooking equipment tools

- Espresso needs to be ground how thick and thin scale entry Italian Coffee Machine Bean Grinder investigation and Grinding course

- How much does it cost to open a small private cafe? How much does it cost to learn coffee? How to operate it?

- The difference between the flavor characteristics of hand-brewed coffee and coffee maker is hand-brewed coffee really better than coffee maker? Can I use a coffee machine to make coffee beans by hand?

- The difference between 01 and 02 of hario v60 filter cup what is the difference between 01 and 02 filter cup opening and cooking flavor

- What's the difference between the smart cup and the French kettle? Which is better, the French kettle or the Smart Cup?

- What's the difference between a smart cup and a V60 filter cup? The difference between the taste of smart cup and hand-brewed coffee